Manual 2100-435D

Page

12 of 38

FRESH AIR INTAKE

This unit is equipped with a fresh air damper assembly.

The damper blade is locked in the closed position when

the unit is shipped from the Factory. To allow the

damper to operate remove the two plastic locking pins,

one on each end of the blade. This will allow for

maximum fresh air flow. The damper blade will now

open when the indoor blower is operating. If less than

maximum fresh air flow is required, reinsert the plastic

pins to limit damper blade opening to desired level.

Two extra pins are provided (taped to the inside of the

assembly) which may be used to hold the blade in some

position other than minimum or maximum position.

This fresh air assembly is located in the rear of the unit

and to gain access to make these adjustments remove

the air filter service door.

All capacity, efficiency and cost of operation

information as required for Department of Energy

“Energyguide” Fact Sheets are based upon the fresh air

blank-off plate in place and is recommended for

maximum energy efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

For details on energy recovery ventilation see separate

section.

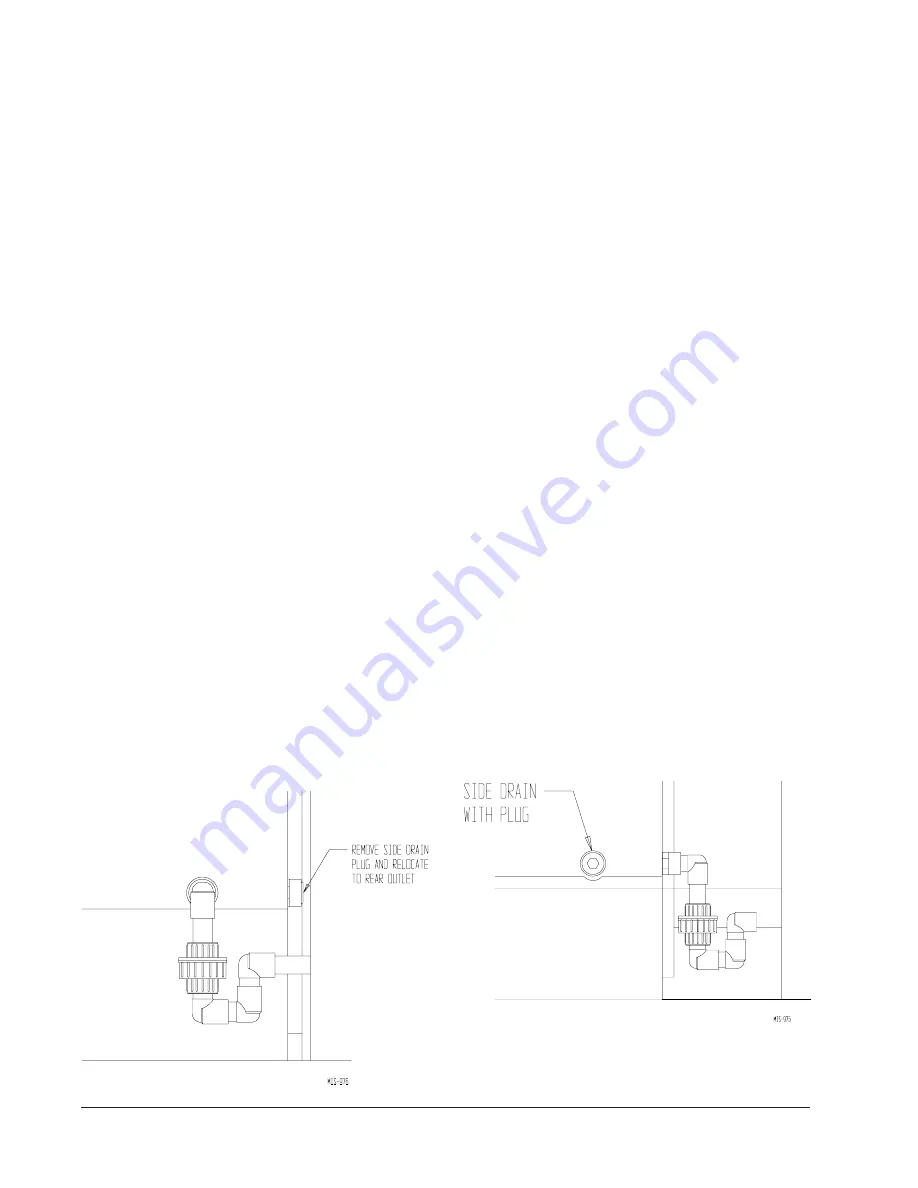

CONDENSATE DRAIN

There are two drain connections on the unit. The rear

drain is the primary drain, and is located on the right

lower rear panel of the unit. The optional side drain is

located on the bottom right side of the unit. The side

drain is shipped with a plug installed.

The

side drain

requires a water trap for proper drainage.

See Figure 9. The drain can be routed through the floor

or through the wall.

If the drain is to be routed

through an unconditioned space, it must be protected

from freezing.

The drain line must be able to be

removed from the unit if it is necessary to remove the

unit from the wall. When the side drain is used, the plug

must be removed and installed in the rear drain outlet.

The

rear drain

can be used with wall thickness of up to

10 inches where a water trap can be installed between

the unit and the interior wall. See Figure 10. The trap

cannot extend beyond the edge of the unit or it will

interfere with the wall mounting bracket. The drain can

be routed through the floor or through the wall. If the

drain is routed through the wall, the drain line must be

positioned such that it will not interfere with the sleeve

flange or the grille. See Figure 11.

If the drain is to be

routed through an unconditioned space, it must be

protected from freezing.

Optional rear drain kits, both standard and heated

versions, are available to facilitate easy installation, and

also removability of heat pump for service.

FIGURE 9

OPTIONAL SIDE DRAIN (SIDE VIEW)

INSTALLATION

QT

EC

UNIT

FIGURE 10

STANDARD REAR DRAIN

Summary of Contents for QTEC QH303D

Page 7: ...Manual 2100 435D Page 7 of 38 FIGURE 1 UNIT DIMENSIONS...

Page 26: ...Manual 2100 435D Page 26 of 38 MIS 1627 FIGURE 17 FRESH AIR DAMPER REMOVAL MOUNTING SCREW...

Page 30: ...Manual 2100 435D Page 30 of 38 FIGURE 20 QTEC DEHUMIDIFICATION MODE CIRCUIT DIAGRAM MIS 1088...

Page 31: ...Manual 2100 435D Page 31 of 38 FIGURE 21 QTEC COOLING MODE CIRCUIT DIAGRAM MIS 1089...