Manual

2100-435D

Page

23 of 38

START UP

DESCRIPTION OF STANDARD

EQUIPMENT

Solid State Electronic Heat Pump Control

Provides efficient 30 minute defrost cycle. A thermistor

sensor and speed up terminal for service along with a 10

minute defrost override are standard on the electronic

heat pump control.

High / Low Pressure Switch

Provides refrigerant circuit high pressure and loss of

charge protection. Includes lockout circuit that is

resettable from room thermostat.

Five Minute Compressor Time Delay

Provides short cycle protection for the compressor

which extends compressor life. Built into the electronic

heat pump control as standard.

Service Light

One service light indicates when service is required.

• Check System – detects high or low pressure

switch operation for compressor protection.

OPTIONAL CFM (QH362, QH422, QH482

AND QH602 ONLY)

These units are shipped from the factory set to operate at

the optional CFM level shown in Table 9. This provides

lower operating sound levels for non-ducted, free

discharge applications. This CFM level will reduce the

system capacity performance by approximately 2% at

the same energy efficiency.

Rated CFM is required for ducted applications for

maximum performance rating. To obtain full CFM on

these models, connect jumper wire as follows:

1. Disconnect all power to the unit. Failure to do so

may result in damage to the motor.

2. Open Return Air access panel.

3. Open inner control panel cover.

4. Locate low voltage terminal strip. There is a pink

jumper wire with both ends attached to terminal

marked “G2”. Move one end of the jumper to

terminal “Y”

5. Reverse steps to reassemble.

IMPORTANT INSTALLER NOTE

For improved start-up performance, wash the indoor coil

with a dishwasher detergent.

PHASE MONITOR

All units with three phase scroll compressors are

equipped with a 3 phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the Y signal is present at the phase monitor

and phases are correct the green LED will light.

If phases are reversed, the red fault LED will be lit and

compressor operation is inhibited.

If a fault condition occurs, reverse two of the supply

leads to the unit. Do not reverse any of the unit factory

wires as damage may occur.

THREE PHASE SCROLL COMPRESSOR

START UP INFORMATION

Scroll compressors, like several other types of

compressors, will only compress in one rotational

direction. Direction of rotation is not an issue with

single phase compressors since they will always start

and run in the proper direction.

However, three phase compressors will rotate in either

direction depending upon phasing of the power. Since

there is a 50-50 chance of connecting power in such a

way as to cause rotation in the reverse direction,

verification of proper rotation must be made.

Verification of proper rotation direction is made by

observing that suction pressure drops and discharge

pressure rises when the compressor is energized.

Reverse rotation also results in an elevated sound level

over that with correct rotation, as well as, substantially

reduced current draw compared to tabulated values.

Verification of proper rotation must be made at the

time the equipment is put into service. If improper

rotation is corrected at this time there will be no

negative impact on the durability of the compressor.

However, reverse operation for oven one hour may

have a negative impact on the bearing due to oil pump

out.

All three phase scroll compressors used in the QT

EC

series are wired identically internally. As a result, once

the correct phasing is determined for a specific system

or installation, connecting properly phased power leads

to the same Fusite terminal should maintain proper

rotation direction. The direction of rotation of the

motor may be changed by reversing any two line

connections to the unit.

Summary of Contents for QTEC QH303D

Page 7: ...Manual 2100 435D Page 7 of 38 FIGURE 1 UNIT DIMENSIONS...

Page 26: ...Manual 2100 435D Page 26 of 38 MIS 1627 FIGURE 17 FRESH AIR DAMPER REMOVAL MOUNTING SCREW...

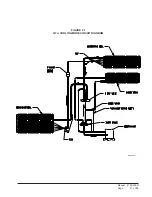

Page 30: ...Manual 2100 435D Page 30 of 38 FIGURE 20 QTEC DEHUMIDIFICATION MODE CIRCUIT DIAGRAM MIS 1088...

Page 31: ...Manual 2100 435D Page 31 of 38 FIGURE 21 QTEC COOLING MODE CIRCUIT DIAGRAM MIS 1089...