Manual 2100-435D

Page

28 of 38

SEQUENCE OF OPERATION

Cooling

– Circuit R-Y makes the thermostat pull in the

compressor contactor starting the compressor and

outdoor motor. The G (indoor motor) circuit is

automatically completed on any call for cooling

operation, or can be energized by manual fan switch on

subbase for constant air circulation.

Heating

– A 24V solenoid coil on reversing valve

controls heating cycle operation. Two thermostat

options, one allowing “Auto” change over from cycle to

cycle and the other constantly energizing solenoid coil

during heating season and thus eliminating pressure

equalization noise except during defrost, are to be used

on “Auto” option, a circuit is completed for R-W1 and

R-Y on each heating “on” cycle, energizing reversing

valve solenoid and pulling in compressor contactor

starting compressor and outdoor motor. R-G also makes

starting indoor blower motor. Heat pump heating cycle

now in operation.

The second option has no “Auto” change over position,

but instead energizes the reversing valve solenoid

constantly whenever the system switch on subbase is

placed in “Heat” position, the “B” terminal being

constantly energized from R. A thermostat demand for

heat completes R-Y circuit, pulling in compressor

contactor starting compressor and outdoor motor. R-G

also make starting indoor blower motor.

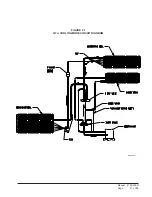

Reheat Circuit

– There is a small capillary tube inserted

between the reheat coil return line and suction line that

will prevent liquid from accumulating in the reheat coil

when it is inactive. This drain does not affect the

normal operation of the system.

There is a check valve located in the reheat coil return

line. It has a soft spring to hold the ball on the seat. This

will make the method of checking the ball freedom with

a magnet difficult. Refer to Figures 18 and 19 for the

location of the check valve and drain back capillary.

When the system is operating in the dehumidification

mode the suction pressure will be reduced by 4 to 8 psig

and the discharge pressure will be reduced by 19 to 22

psig.

Return Air Thermostat

– In dehumidification mode if

the return air temperature is lower than 65°, the return

air thermostat closes and brings on stage one electric

heat to maintain 65°.

High / Low Pressure Control

provides protection for

the compressor. In the event system pressures go above

350 PSI or below 3.5 PSI in either cooling or heating

mode the compressor will be stopped. This will activate

the red light located in the control panel. The lockout

circuit will hold compressor off line. When the system

problem is corrected, the unit operation can be restored

by turning of the main power supply off and then back

on, or reset the room thermostat. The low pressure

control has a bypass to eliminate nuisance lockout on

cold start up.

The bypass timer should be set to 200 seconds. this is to

assure there is no nuisance tripping of the low-pressure

control during startup in heating mode under cold

weather conditions. See Figure 19.

OPTIONAL CLIMATE CONTROLS

SEQUENCE OF OPERATION

The Climate Control

Option E

is an electronic,

programmable thermostat and a humidistat. This unit

has a refrigerant reheat circuit that is controlled by a 3

way valve.

When the humidity is above the setpoint of the

humidistat, the compressor circuit and the 3 way valve

are energized and the evaporator air flow is reduced.

The 3 way valve directs hot discharge gas into a

separate desuperheating condenser circuit that reheats

the conditioned air before it is delivered to the room.

When the humidistat is satisfied, the system switches

back to normal air conditioning mode.

If the thermostat calls for cooling during

dehumidification mode, the call for cooling takes

precedence over the dehumidification and the unit will

cool until the thermostat is satisfied. Once the call for

cooling is satisfied, the unit may continue to

dehumidify.

If the thermostat calls for heat when the unit is in the

dehumidification mode, the electric heaters will

energize and the evaporator air flow will return to the

heating air flow. When the thermostat is satisfied, the

electric heaters will turn off and the air flow will be

reduced and the system will continue to dehumidify

until humidistat is satisfied.

If the unit is running in heat pump mode and the

humidistat calls for dehumidification, the

dehumidification mode takes precedence over the heat

pump heating mode. The unit will not return to the

heating mode until 2nd stage heating is called for.

The Climate Control

Option F

has a non-programmable

electronic thermostat, timer, and humidistat. This unit

has a refrigerant reheat circuit that is controlled by a

3 way valve.

Unit operation is controlled by the manually operated

timer. Normal heating, cooling or ventilation is

available only when the timer is on. Dehumidification

can be set to be available only when the timer is on, or

to be available continuously by switching a jumper on

the relay logic board. See notes on Table 12.

Fan thermostat output should be programmed to be on

continuously when used with a vent option.

When the humidity is above the setpoint of the

humidistat, the compressor circuit and the 3 way valve

are energized and the evaporator air flow is reduced.

The 3 way valve directs hot discharge gas into a

separate desuperheating condenser circuit that reheats

the conditioned air before it is delivered to the room. If

Summary of Contents for QTEC QH303D

Page 7: ...Manual 2100 435D Page 7 of 38 FIGURE 1 UNIT DIMENSIONS...

Page 26: ...Manual 2100 435D Page 26 of 38 MIS 1627 FIGURE 17 FRESH AIR DAMPER REMOVAL MOUNTING SCREW...

Page 30: ...Manual 2100 435D Page 30 of 38 FIGURE 20 QTEC DEHUMIDIFICATION MODE CIRCUIT DIAGRAM MIS 1088...

Page 31: ...Manual 2100 435D Page 31 of 38 FIGURE 21 QTEC COOLING MODE CIRCUIT DIAGRAM MIS 1089...