Manual

2100-435D

Page

35 of 38

FAN BLADE SETTING DIMENSIONS

Any service work requiring removal or adjustment in

the fan and/or motor area will require that the

dimensions in Table 7 be checked and blade adjusted in

or out of the motor shaft accordingly.

1

Maximum ESP (inches WC) shown is with 1" thick disposable filter (reduced by .2 for 2" filter).

2

Rated CFM for ducted applications – required for maximum performance rating. To obtain full CFM on models QH363, QH423, QH483 and

QH603 connect the pink jumper wire (provided) to terminal #G2 and #Y on the low voltage terminal block located in the circuit breaker box.

3

Optional CFM – the unit is shipped from the factory set to operate at the optional CFM level shown. This provides lower operating sound

levels for non-ducted, free discharge applications. This reduces system capacity performance by approximately 2% at the same energy

efficiency.

4

Continuous fan CFM is the total air being circulated during continuous fan mode.

5

Indoor air flow during periods of high humidity when system is operating under control of optional humidistat for maximum humidity reduction.

6

Models QH243 – when operating on 2nd stage heating the indoor air will increase to 1000 CFM.

REFRIGERANT CHARGE

The correct system R-22 charge is shown on the unit

rating plate. Optimum unit cooling performance will

occur with a refrigerant charge resulting in a Super Heat

as shown in Table 8. If correct charge is in doubt,

recover the refrigerant and recharge per the charge on

the unit rating plate.

FIGURE 23

FAN BLADE SETTING

MIS-983

TABLE 7

FAN BLADE DIMENSIONS

L

E

D

O

M

A

N

O

I

S

N

E

M

I

D

)

S

E

H

C

N

I

(

4

4

2

H

Q

0

5

7

.

3

0

3

H

Q

0

5

7

.

3

6

3

H

Q

0

5

7

.

3

2

4

H

Q

0

5

7

.

3

8

4

H

Q

0

5

7

.

3

0

6

H

Q

0

5

7

.

TABLE 8

SUPER HEAT AT COMPRESSOR

L

E

D

O

M

D

E

T

A

R

M

F

C

D

O

F

°

5

9

E

R

U

T

A

R

E

P

M

E

T

D

O

F

°

2

8

E

R

U

T

A

R

E

P

M

E

T

4

4

2

H

Q

0

0

8

8

1

-

6

1

6

1

-

4

1

3

0

3

H

Q

0

0

0

1

8

1

-

6

1

7

1

-

5

1

3

6

3

H

Q

0

0

2

1

8

1

-

6

1

6

1

-

4

1

3

2

4

H

Q

0

0

2

1

1

2

-

9

1

8

1

-

6

1

3

8

4

H

Q

0

0

4

1

5

2

-

3

2

4

2

-

2

2

3

0

6

H

Q

0

5

5

1

9

-

7

5

1

-

3

1

NOTE: These units are equipped with a variable speed (ECM) indoor motor that automatically adjust itself to maintain

approximately the same rate of indoor air flow in both heating and cooling, dry and wet coil conditions and at

both 230/208 or 460 volts.

TABLE 9

INDOOR BLOWER PERFORMANCE

l

e

d

o

M

P

S

E

d

e

t

a

R

1

P

S

E

.

x

a

M

2

d

e

t

a

R

M

F

C

3

l

a

n

o

i

t

p

O

M

F

C

4

s

u

o

u

n

i

t

n

o

C

B

F

C

5

n

o

i

t

a

c

i

f

i

d

i

m

u

h

e

D

M

F

C

@

M

F

C

P

X

E

.

x

a

M

4

4

2

H

Q

6

0

1

.

5

.

0

0

0

8

-

-

-

-

-

0

0

8

0

0

5

0

0

7

3

0

3

H

Q

5

1

.

8

.

0

0

0

0

1

-

-

-

-

-

0

0

0

1

0

0

7

0

1

9

3

6

3

H

Q

5

1

.

8

.

0

0

0

2

1

0

0

0

1

0

0

0

1

0

5

8

5

7

1

1

3

2

4

H

Q

5

1

.

8

.

0

0

0

2

1

0

0

0

1

0

0

0

1

0

5

8

5

7

1

1

3

8

4

H

Q

5

1

.

8

.

0

0

0

4

1

0

0

1

1

0

0

1

1

0

5

8

5

7

1

1

3

0

6

H

Q

0

2

.

5

.

0

0

5

5

1

0

5

2

1

0

5

2

1

0

5

2

1

0

0

4

1

Summary of Contents for QTEC QH303D

Page 7: ...Manual 2100 435D Page 7 of 38 FIGURE 1 UNIT DIMENSIONS...

Page 26: ...Manual 2100 435D Page 26 of 38 MIS 1627 FIGURE 17 FRESH AIR DAMPER REMOVAL MOUNTING SCREW...

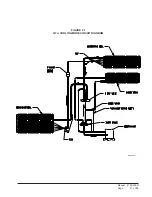

Page 30: ...Manual 2100 435D Page 30 of 38 FIGURE 20 QTEC DEHUMIDIFICATION MODE CIRCUIT DIAGRAM MIS 1088...

Page 31: ...Manual 2100 435D Page 31 of 38 FIGURE 21 QTEC COOLING MODE CIRCUIT DIAGRAM MIS 1089...