Manual

2100-435D

Page

9 of 38

HANDLING UNIT AFTER REMOVAL

FROM SKID

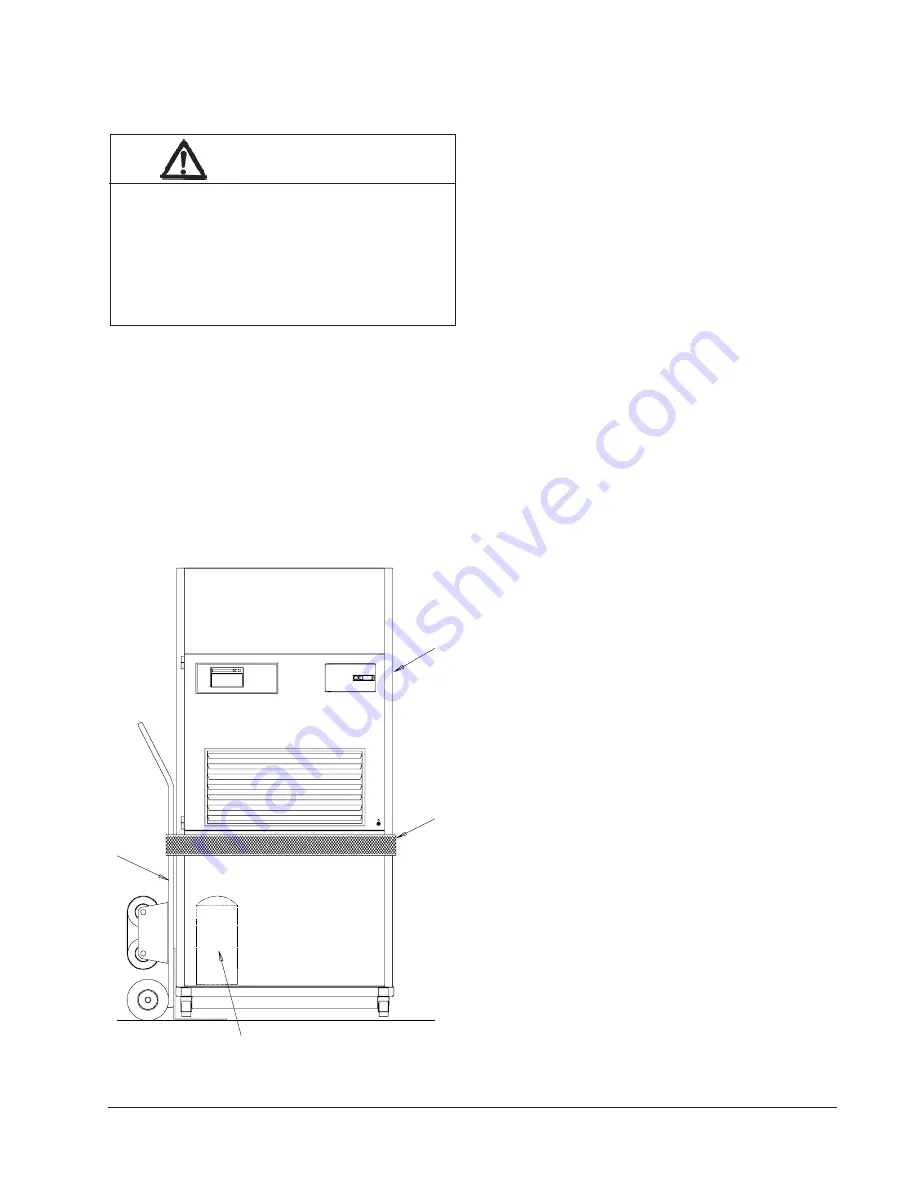

FIGURE 4

UNIT ON APPLIANCE CART

The unit will have to be turned sideways and removed

from the skid to fit through a 36" doorway. If the door

height allows, the unit can be slid sideways through the

door.

If the unit can not be slid through the door, then the unit

will have to be put on a cart and tipped down to roll

through the door. It is recommended that an appliance

cart by used with a strap to hold the unit on the cart.

The wheels of the unit

must be locked

. If the wheels

were allowed to roll, the unit could roll off the cart.

The

unit should always be carted from the left side

. This is

the side where the compressor is located. See Figure 4.

The blade of the appliance cart should be slid under the

wheels of the unit. The strap of the appliance cart

should be placed around the unit and strapped tightly.

Help will be required to tip the unit back onto the cart.

The unit can be leaned far enough back to be rolled

through the door. Be careful when setting the unit back

up to keep from damaging the unit.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The unit is designed for use with or without duct work.

For use without duct work, Plenum Box QPB42 is

recommended.

These instructions explain the recommended method to

install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Start

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 3 for information on codes and

standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Systems of

Other Than Residence Type, NFPA No. 90A, and

Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

MINIMUM INSTALLATION HEIGHT

The minimum installation height of the unit with a Free

Blow Plenum is 8 ft. 6 in. This provides enough

clearance for the plenum to be removed. See Figure 5.

The minimum installation height for ducted applications

is 8 ft. 4½ in. This provides enough clearance to install

the duct work. See Figure 6.

WARNING

Exercise extreme caution when pushing the

unit on the rollers. Handle and push from the

lower 1/3 of the unit. Insure that debris is not

on the floor where the unit is to be moved on

the rollers. Failure to do so could result in the

unit tipping over and causing bodily injury and/

or damage to the unit.

QT

EC

UNIT

(Right Side)

APPLIANCE

CART

COMPRESSOR

MIS-1555

STRAP

Summary of Contents for QTEC QH303D

Page 7: ...Manual 2100 435D Page 7 of 38 FIGURE 1 UNIT DIMENSIONS...

Page 26: ...Manual 2100 435D Page 26 of 38 MIS 1627 FIGURE 17 FRESH AIR DAMPER REMOVAL MOUNTING SCREW...

Page 30: ...Manual 2100 435D Page 30 of 38 FIGURE 20 QTEC DEHUMIDIFICATION MODE CIRCUIT DIAGRAM MIS 1088...

Page 31: ...Manual 2100 435D Page 31 of 38 FIGURE 21 QTEC COOLING MODE CIRCUIT DIAGRAM MIS 1089...