Manual 2100-419E

Page

25 of 48

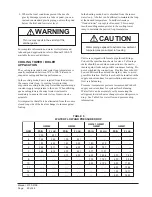

OPTIONAL CFM

This option is not available for QW241 or QW301.

These units are shipped from the factory set to operate at

the optional CFM level shown in Table 4. This provides

lower operating sound levels for non-ducted, free

discharge applications. This CFM level will reduce the

system capacity performance by approximately 2% at

the same energy efficiency.

Rated CFM is required for ducted applications for

maximum performance rating. To obtain full CFM on

these models, connect jumper wire as follows:

1. Disconnect all power to the unit. Failure to do so

may result in damage to the motor.

2. Open hinged return air grille panel

3. Open control panel cover.

4. Locate low voltage terminal strip. There is a pink

jumper wire with both ends attached to terminal

marked “G2”. Move one end of this jumper to

terminal “Y”.

5. Reverse steps to reassemble.

IMPORTANT INSTALLER NOTE

For improved start up performance, wash the indoor coil

with dishwashing detergent.

PHASE MONITOR

All units with three phase scroll compressors are

equipped with a three phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the Y signal is present at the phase monitor

and phases are correct, the green LED will light and

contactor will energize. If phases are reversed, the red

fault LED will be lit and compressor operation is

inhibited.

If a fault condition occurs, reverse two of the supply

leads to the unit. Do not reverse any of the unit factory

wires as damage may occur.

SERVICE HINTS

1. Caution user to maintain clean air filters at all times.

Also, not to needlessly close off supply air registers.

This may reduce air flow through the system which

shortens equipment service life as well as increasing

operating costs and noise levels.

2. The heat pump wall thermostats perform multiple

functions. Be sure that all function switches are

correctly set for the desired operating mode before

trying to diagnose any reported service problems.

SEQUENCE OF OPERATION

COOLING

– Circuit R-Y makes the thermostat pull in

the compressor contactor starting the compressor. The

G (indoor motor) circuit is automatically completed on

any call for cooling operation, or can be energized by

manual fan switch on subbase for constant air

circulation.

DELAY ON MAKE TIMING

s

e

t

u

n

i

m

5

0

.

)

s

d

n

o

c

e

s

0

3

(

B

O

D

=

M

O

D

s

d

n

o

c

e

s

3

2

1

s

e

t

u

n

i

m

0

.

1

)

s

d

n

o

c

e

s

0

6

(

B

O

D

=

M

O

D

s

d

n

o

c

e

s

6

2

1

s

e

t

u

n

i

m

0

.

2

)

s

d

n

o

c

e

S

0

2

1

(

B

O

D

=

M

O

D

s

d

n

o

c

e

s

2

3

1

s

e

t

u

n

i

m

0

.

3

)

s

d

n

o

c

e

s

0

8

1

(

B

O

D

=

M

O

D

s

d

n

o

c

e

s

8

3

1

s

e

t

u

n

i

m

0

.

4

)

s

d

n

o

c

e

s

0

4

2

(

B

O

D

=

M

O

D

s

d

n

o

c

e

s

4

4

1

s

e

t

u

n

i

m

0

.

5

)

s

d

n

o

c

e

s

0

0

3

(

B

O

D

=

M

O

D

s

d

n

o

c

e

s

0

5

1

Summary of Contents for QW242

Page 6: ...Manual 2100 419E Page 6 of 48 FIGURE 1 UNIT DIMENSIONS ...

Page 21: ...Manual 2100 419E Page 21 of 48 FIGURE 15 REMOTE THERMOSTAT WIRING DIAGRAM X OPTION ...

Page 41: ...Manual 2100 419E Page 41 of 48 FIGURE 27 WATER SOURCE HEAT PUMP COOLING CYCLE MIS 329 ...

Page 42: ...Manual 2100 419E Page 42 of 48 FIGURE 28 WATER SOURCE HEAT PUMP HEATING CYCLE MIS 328 ...