Manual

2100-319F

Page

7 of 10

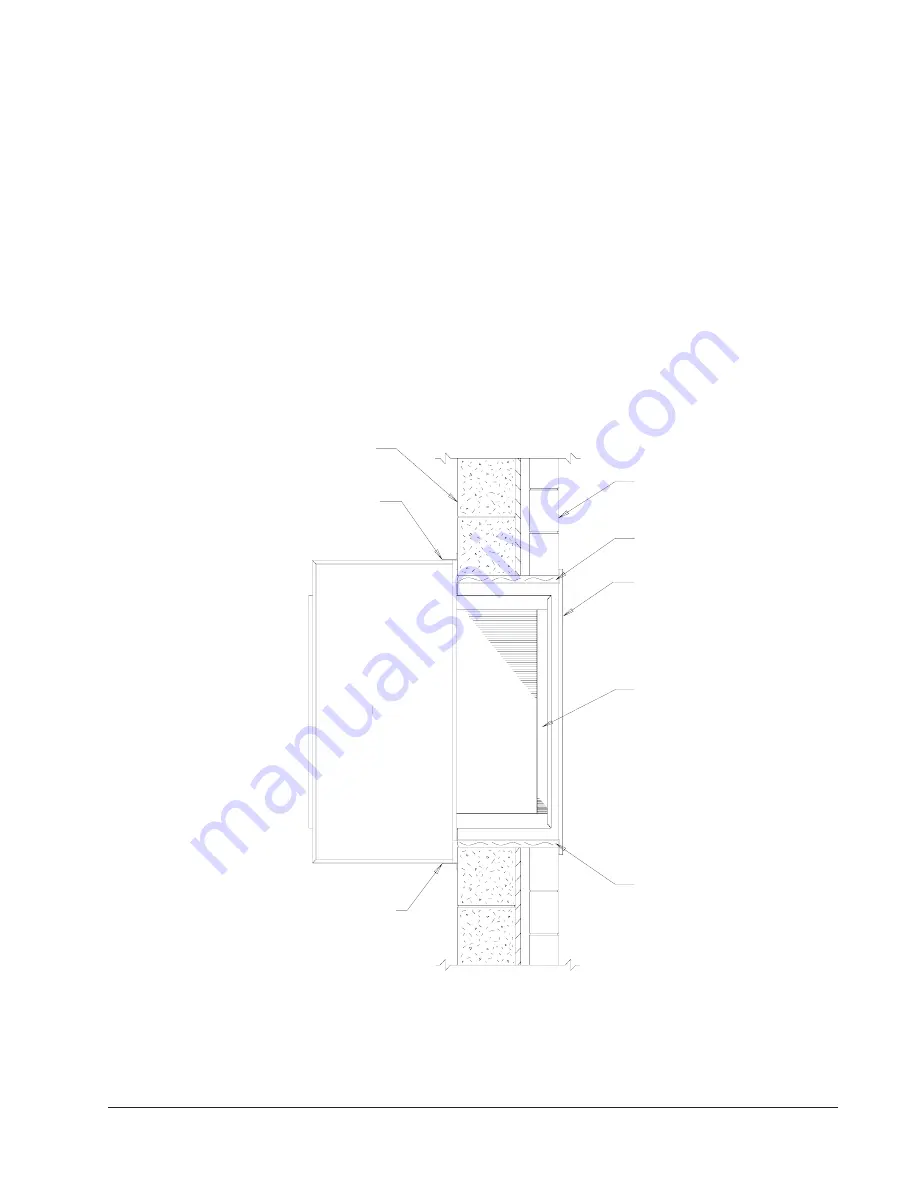

FIGURE 5

TYPICAL INSTALLATION WITH 14" MAX. WALL THICKNESS

sealant must be applied as required. The sleeve must be

anchored to the wall. All four mounting flanges must be

fastened with two fasteners each to the outside wall.

The gaps between the side flanges, and the top and

bottom flanges must be sealed to the wall.

On the inside of the building, the gaps between the

sleeve and the opening must be filled with insulation.

This will help insulate the sleeve and prevent infiltration

of any unwanted outdoor air. See Figure 5.

If the QT

EC

unit will be drained through the wall, the

drain line must be installed through the wall.

Information for the drain installation is contained in the

QT

EC

Installation Instructions.

square in the opening. A slope is built into the bottom of

the sleeve from the inside to the outside. This will allow

any water that gets into the sleeve to drain out. Once the

test fitting has been checked out, the sleeve should be

removed from the wall.

With the sleeve removed, two 1/4 inch beads of sealant

must be applied to the flanges that contact the outside

wall. See Figure 3

The sleeve must be installed back in the wall making

sure that the predrilled holes in the wall line up with the

holes in the mounting flanges of the sleeve. Check to

make sure that there is enough sealant between the wall

and the flanges to make the joint watertight. Additional

INSIDE

WALL

WALL BRACKET

QTEC UNIT

OUTSIDE WALL

INSULATION

OUTDOOR GRILLE

CONDENSER COIL AND FAN

INSERTED INTO SLEEVE

WALL BRACKET

INSULATION

TOP SECTION VIEW