Manual 2100-279

Page 3

3.1

BASIC OPERATION – HEATING CYCLE

This furnace is operated by an Electronic Blower Control

(EBC) and a gas control system which controls all functions

of the furnace.

On a call for heat from the thermostat, the EBC first turns on

the inducer motor. The pressure switch then closes

signaling the ignition control to proceed with ignition

function.

The ignition system consists of an intermittent pilot with a

hot surface igniter to light pilot burner, senses flame, and

then main gas valve opens with pilot flame lighting main

burners.

There is a 60 second delay after main burner is on until the

comfort air blower starts on heating (low) speed. After the

thermostat is satisfied, the burners will go off as gas

valve closes. The inducer will continue to run for 5

seconds, and the comfort air blower will continue to run for

two minutes.

3.2

BASIC OPERATION – COOLING CYCLE

On a call for cool the compressor and condenser fan will

start immediately, and the comfort air blower will start 6

seconds later on cooling (high) speed. When the thermostat

is satisfied the compressor and condenser fan will stop, and

the comfort air blower will continue to operate for 60

seconds.

3.2.1 COMPRESSOR LOCKOUT (CANADIAN

UNITS ONLY)

The units built for Canadian use are equipped with high and

low pressure controls. These controls protect the

compressor from extreme conditions such as high refrigerant

pressure or a loss of charge. When this happens the

compressor is held off line by a lock out relay. To reset the

lock out relay, the thermostat must be set to the “OFF”

position and then returned to the normal operating position.

The compressor is now allowed to function. If the

compressor continues to lock out, service personnel should

be called to check the unit.

3.3

MANUAL FAN (CONTINUOUS AIRFLOW)

OPERATION

If wall thermostat is set to MANUAL (ON) position to

operate comfort air blower continuously to provide air

circulation throughout the building, the blower will

operate on the heating speed rather than the cooling as is

typical with most systems. This permits the air to

circulate as desired but helps keep the operating noise

level down as well as conserving energy.

During a call for cooling, the blower automatically shifts up

to cooling speed, and remains there until 60 seconds

after thermostat is satisfied then drops back to heating

speed.

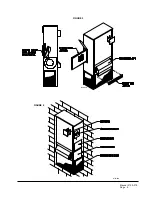

SECTION 3 • UNDERSTANDING HOW

YOUR FURNACE WORKS

Your installer should have given you a detailed explanation

of how the furnace operates. Shown below are the basic

operation characteristics and sequence of operation. If you

have any questions consult your installer and/or service

agency.

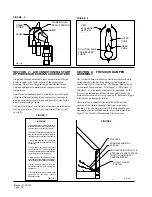

This furnace is equipped with a vent shut-off system which

monitors the combustion air into the burners by means of a

pressure sensing device. When the vent becomes blocked,

this device turns off the gas valve circuit to prevent flue

products from entering the structure. In the event that this

occurs, shut off furnace and contact a qualified service

agency.

2.3. ALTERATION OF FURNACE CONTROLS

WARNING

Never store anything combustible near or on

your furnace. These include brooms,

dustmops, vacuum cleaners, other cleaning

tools or items, plastic or plaxtic containers,

paper bags or other paper products. A fire

could occur resulting in damage, injury or

death.

WARNING

Do not alter any gas or electrical controls (gas

control, pilot or safety controls) in any manner.

Altering them could cause furnace to operate

unsafely resulting in damage, injury or death.

There are many types of thermostats

compatible with this furnace. Make sure you

understand the specific type installed. Ask

installer for detailed explanation, and retain

thermostat instruction manual for reference.

* * IMPORTANT * *