Manual 2100-365Q

Page

20 of 73

ELECTRICAL GROUNDING

When installed, the furnace must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or Canadian Electrical Code,

CSA22.1, latest edition. Use a copper wire from green

ground wire on the furnace to a grounded connection in

the service panel or a properly driven and electrically

grounded ground rod. See Tables 1 & 1A for proper

ground wire size.

FIELD INSTALLED EQUIPMENT

Wiring to be done in the field between the furnace and

devices not attached to the furnace, or between separate

devices which are field installed and located, shall

conform with the temperature limitation for Type T

wire {63 degrees F rise (36 degrees C)} when installed

in accordance with the manufacturer’s instructions.

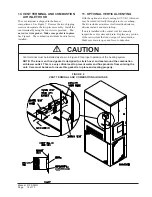

INSTALLATION OF FLEXIBLE CONDUIT

THROUGH RETURN AIR OPENING

NOTE: To allow proper clearance between the

control panel and any vent options, 90°

conduit fittings must be used on the back of

the control panel.

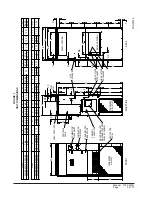

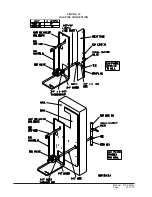

INSTALLING CONDUIT (See Figure 10.)

1. Remove conduit access panel if required to gain

access to area behind control panel.

2. Remove low voltage and high voltage knockouts

located in rear of control panel.

3. Run low voltage conduit through 7/8 bushing located

in conduit entrance plate and secure to low voltage

opening in rear of control panel.

4. Run high voltage conduit through 1-3/4 bushing

located in conduit entrance plate and secure to high

voltage opening in rear of control panel.

5. Replace conduit access panel if required to complete

installation.

6. Seal around conduit in conduit entrance plate.

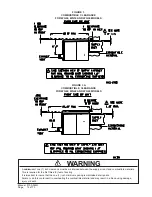

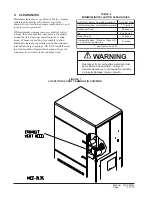

WARNING

Failure to provide a proper electrical ground

could result in electric shock or fire.

15. WIRING – MAIN POWER

Refer to unit rating plate for wire sizing information

and maximum fuse or “HACR” type circuit breaker

size. Each outdoor unit is marked with a “Minimum

Circuit Ampacity”. This means that the field wiring

used must be sized to carry that amount of current. All

models are suitable only for connection with copper

wire. Each unit and/or wiring diagram will be marked -

“

Use Copper Conductors Only

”. These instructions

must be

adhered to. Refer to the National Electrical

Code (NEC) for complete current carrying capacity

data on the various insulation grades of wiring material.

All wiring must conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75° C

copper) for all models.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR” type circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection and also to assure that

there will be no nuisance tripping due to the momentary

high starting current of the compressor motor.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect. To

convert for the locking capability bend the tab located

in the bottom left hand corner of the disconnect opening

under the disconnect access panel straight out. This tab

will now line up with the slot in the door. When shut, a

padlock may be placed through the hole in the tab

preventing entry.

See “Start Up” section for important information on

three phase scroll compressor start ups.

WARNING

For your personal safety, turn off electric

power at service entrance panel before

making any electrical connections. Failure to

do so could result in electric shock or fire.

WARNING

Failure to provide an electrical power supply

shut off means could result in electric shock

or fire.

Summary of Contents for WG242-A

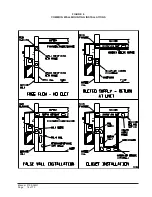

Page 13: ...Manual 2100 365Q Page 13 of 73 FIGURE 2A MOUNTING INSTRUCTIONS FOR WG42 WG48 AND WG60...

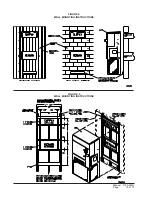

Page 16: ...Manual 2100 365Q Page 16 of 73 FIGURE 6 COMMON WALL MOUNTING INSTALLATIONS...

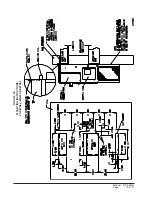

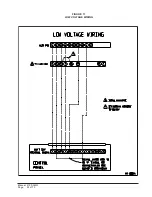

Page 22: ...Manual 2100 365Q Page 22 of 73 FIGURE 11 LOW VOLTAGE WIRING...

Page 23: ...Manual 2100 365Q Page 23 of 73 FIGURE 12 GAS PIPE CONNECTION...

Page 48: ...Manual 2100 365Q Page 48 of 73 WG242 A 230 208 60 1...

Page 49: ...Manual 2100 365Q Page 49 of 73 WG242 A WG362 A 230 208 60 1...

Page 50: ...Manual 2100 365Q Page 50 of 73 WG242 B 230 208 60 3...

Page 51: ...Manual 2100 365Q Page 51 of 73 WG242 B WG362 B 230 208 60 3...

Page 52: ...Manual 2100 365Q Page 52 of 73 WG243 C 460 60 3...

Page 53: ...Manual 2100 365Q Page 53 of 73 WG243 C 460 60 3...

Page 54: ...Manual 2100 365Q Page 54 of 73 WG302 A 230 208 60 1...

Page 55: ...Manual 2100 365Q Page 55 of 73 WG302 A WG482 A WG602 A 230 208 60 1...

Page 56: ...Manual 2100 365Q Page 56 of 73 WG302 B 230 208 60 3...

Page 57: ...Manual 2100 365Q Page 57 of 73 WG302 B WG482 B WG602 B 230 208 60 3...

Page 58: ...Manual 2100 365Q Page 58 of 73 WG303 C 460 60 3...

Page 59: ...Manual 2100 365Q Page 59 of 73 WG303 C 460 60 3...

Page 60: ...Manual 2100 365Q Page 60 of 73 WG362 A 230 208 60 1...

Page 61: ...Manual 2100 365Q Page 61 of 73 WG362 B 230 208 60 3...

Page 62: ...Manual 2100 365Q Page 62 of 73 WG363 C 460 60 3...

Page 63: ...Manual 2100 365Q Page 63 of 73 WG363 C 460 60 3...

Page 64: ...Manual 2100 365Q Page 64 of 73 WG423 A 230 208 60 1...

Page 65: ...Manual 2100 365Q Page 65 of 73 WG423 A 230 208 60 1...

Page 66: ...Manual 2100 365Q Page 66 of 73 WG423 B 230 208 60 3...

Page 67: ...Manual 2100 365Q Page 67 of 73 WG423 B 230 208 60 3...

Page 68: ...Manual 2100 365Q Page 68 of 73 WG424 C 460 60 3...

Page 69: ...Manual 2100 365Q Page 69 of 73 WG424 C 460 60 3...

Page 70: ...Manual 2100 365Q Page 70 of 73 WG482 A WG602 A 230 208 60 1...

Page 71: ...Manual 2100 365Q Page 71 of 73 WG482 B WG602 B 230 208 60 3...

Page 72: ...Manual 2100 365Q Page 72 of 73 WG483 C WG603 C 460 60 3...

Page 73: ...Manual 2100 365Q Page 73 of 73 WG483C WG603 C 460 60 3...

![Roberts Gorden Combat UHD[S] 150-400 Specifications preview](http://thumbs.mh-extra.com/thumbs/roberts-gorden/combat-uhd-s-150-400/combat-uhd-s-150-400_specifications_1469644-1.webp)