Version 3.01

| P2 Series User Guide |

21

www.bardac.com

4

Elec

trical Installation

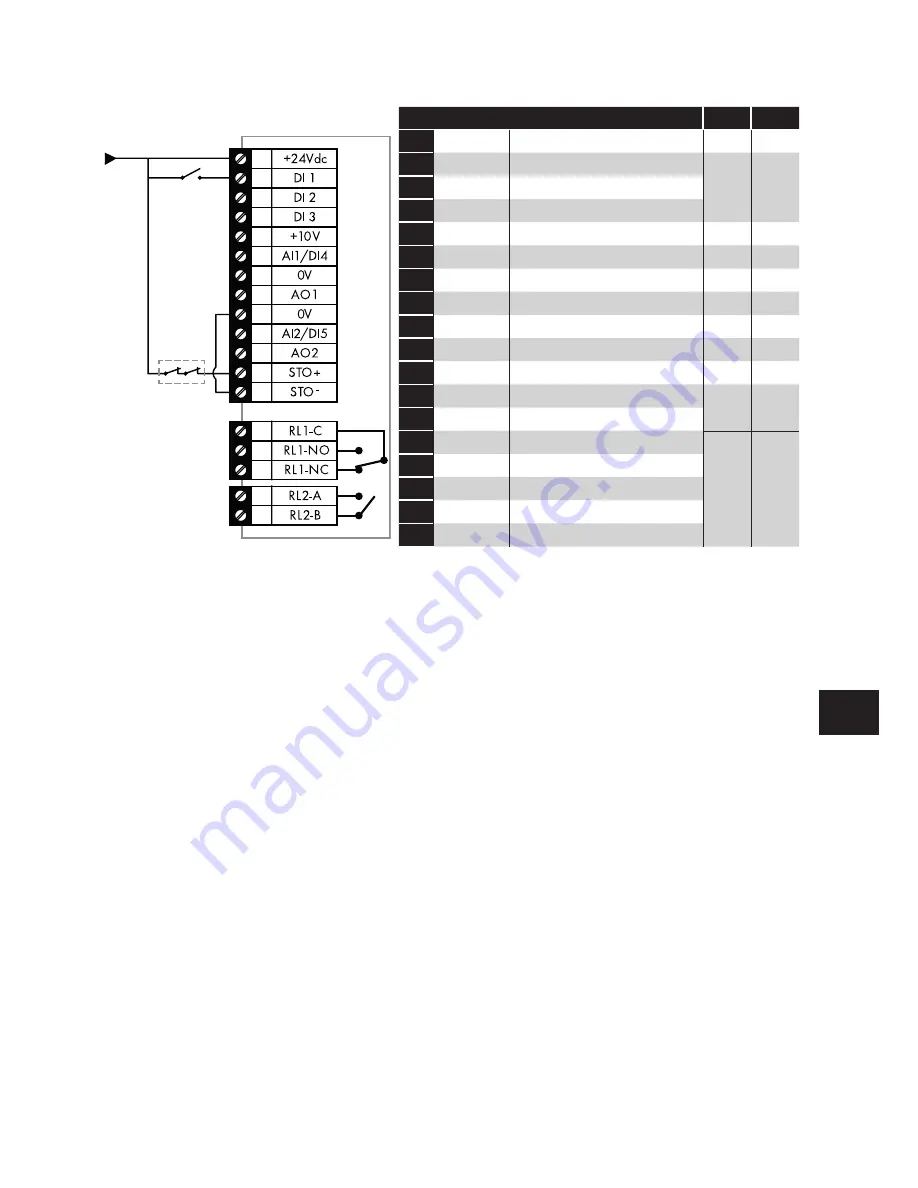

4.1.2. Control Connections

Key

Sec.

Page

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

+24V

24 Volt DC Input / Output

4.10.1

24

2

DI1

Digital Input 1 (Run Enable)

4.10.2

24

3

DI2

Digital Input 2

4

DI3

Digital Input 3

5

+10V

+10Volt DC Output

6

AI1 / DI4

Analog Input 1 / Digital Input 4

4.10.3

24

7

0V

0 Volt Common

8

AO1

Analog Output 1

4.10.4

24

9

0V

0 Volt Common

10

AI2 / DI5

Analog Input 2 / Digital Input 5

4.10.3

24

11

AO2

Analog Output 2

4.10.4

24

12

STO-

STO 0 Volt Connection

4.14

27

13

STO+

STO + 24VDC Connection

14

RL1-C

Relay Output 1 Common

4.10.5

24

15

RL1-NO

Relay Output 1 Normally Open

16

RL1-NC

Relay Output 2 Normally Closed

17

RL2-A

Relay Output 2

18

RL2-B

Relay Output 2

4.2. Protective Earth (PE) (Ground) Connection

4.2.1. Grounding Guidelines

Adequate safety earthing must be provided in accordance with local wiring rules and codes of practice. The ground terminal of each

drive should be connected back to the common safety earth bar to maintain touch potentials within safe limits. The ground terminal of

each drive should be individually connected DIRECTLY to the site ground bus bar (through the EMC filter if installed). The drive ground

connections should not loop from one drive to another, or to, or from any other equipment. Ground impedance must conform to local

industrial safety regulations and/or electrical codes.

To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring connections.

The integrity of all ground connections should be checked periodically.

4.2.2. Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductors.

4.2.3. Motor Ground

The driven motor must be locally connected to a suitable ground location to maintain touch potentials within safe limits. In addition, the

motor ground must be connected to one of the ground terminals on the drive.

4.2.4. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The drive is designed to produce the minimum possible leakage current

whilst complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching

frequency, the earth connections used and the type of RFI filter installed. If an ELCB (Earth Leakage Circuit Breaker) is to be used, the

following conditions apply:

A Type B Device must be used.

The device must be suitable for protecting equipment with a DC component in the leakage current.

Individual ELCBs should be used for each drive.

4.2.5. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal

(drive end) should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to

the safety ground terminal.