C H A N GE PARA METERS

1 1 3

6.10 CHANGE

P

A

R

AMETE

R

S / ZE

R

O

I

NTE

RL

OCKS

PIN number range 1 1 5-1 2 1.

Th

i

s menu

i

s used to enab

l

e 2

i

nter

l

ock

i

ng

funct

i

ons that are assoc

i

ated w

i

th zero speed.

There norma

l

standst

ill

behav

i

our

i

s as fo

ll

o w s.

A fter the sat

i

sfy

i

ng cond

i

t

i

ons of ‘zero speed and

current demand’,

AND

‘zero speed feedback’ are

fu

l

f

ill

ed, the f

i

r

i

ng pu

l

ses are removed and a

ll

other

l

oops rema

i

n act

i

ve to enab

l

e a rap

i

d response for a

ne w request for speed.

1 1 7)ZERO IN TLK SPD % sets the thresho

l

d for

both the zero speed reference and feedback

dec

i

s

i

ons. 1 1 8)ZERO IN TLK C UR % sets the

thresho

l

d for the zero current demand dec

i

s

i

on.

I

f 118

)

ZE

R

O

I

NT

L

K CU

R

%

i

s s

e

t to 0.00% th

e

n

th

e

f

iri

ng pu

l

s

e

s

a

r

e

not

r

e

mov

e

d.

Due to the rap

i

d response of the above mode,

i

t

may be necessary to

i

mp

l

ement

115

)

STANDST

I

LL

ENB

L

. W

i

thout th

i

s quench funct

i

on enab

l

ed the

motor may be cont

i

nuous

l

y mov

i

ng as the system

responds to sma

ll

var

i

at

i

ons, w h

i

ch may be

undes

i

rab

l

e.

i

)

115

)

STANDST

I

LL

ENB

L

prov

i

des an extra

l

eve

l

of

i

nh

i

b

i

t by not on

l

y remov

i

ng the f

i

r

i

ng pu

l

ses but

a

l

so quench

i

ng the

l

oops.

It operates after the sat

i

sfy

i

ng cond

i

t

i

ons of zero

speed reference, and zero speed feedback are

fu

l

f

ill

ed. 1 1 7)ZERO IN TLK SPD % sets the

thresho

l

d for both the zero speed ref and feedback dec

i

s

i

ons.

ii

)

116

)

ZE

R

O

R

EF STA

R

T

. Th

i

s prevents the current contro

l

be

i

ng enab

l

ed after a start command,

i

f the tota

l

speed reference to the dr

i

ve, or the

i

nput to the RUN M O DE RA MPS,

i

s not at zero. It

i

s used

i

f start

i

ng the

motor

i

nadvertent

l

y may be undes

i

rab

l

e. The message C O N T A C T OR LO C K O U T w

ill

appear after

approx

i

mate

l

y 2 seconds

i

f th

i

s funct

i

on

i

s not sat

i

sf

i

ed. The contactor

i

s de-energ

i

sed.

E. g. If an extruder

i

s fu

ll

of co

l

d p

l

ast

i

c, then start

i

ng

i

t may damage the scre w . By

i

mp

l

ement

i

ng th

i

s

funct

i

on the operator has to de

li

berate

l

y set the references to zero before he can commence runn

i

ng.

For these funct

i

ons to w ork the zero thresho

l

d

l

eve

l

s 1 1 7)ZERO IN TLK SPD % and 1 1 8)ZERO IN TLK C UR %

need to be def

i

ned. A

ll

the thresho

l

d

l

eve

l

s are symmetr

i

ca

l

for reverse rotat

i

on and have hyster

i

s

i

s of + /-

0.5 % around the chosen

l

eve

l

.

For systems emp

l

oy

i

ng a shaft encoder there

i

s a sub-menu for

i

mp

l

ement

i

ng sp

i

nd

l

e or

i

entat

i

on and/or zero

speed shaft pos

i

t

i

on

l

ock. In add

i

t

i

on to the ad

j

ustab

l

e parameters there are 4 d

i

agnost

i

c mon

i

tor

i

ng f

l

ags.

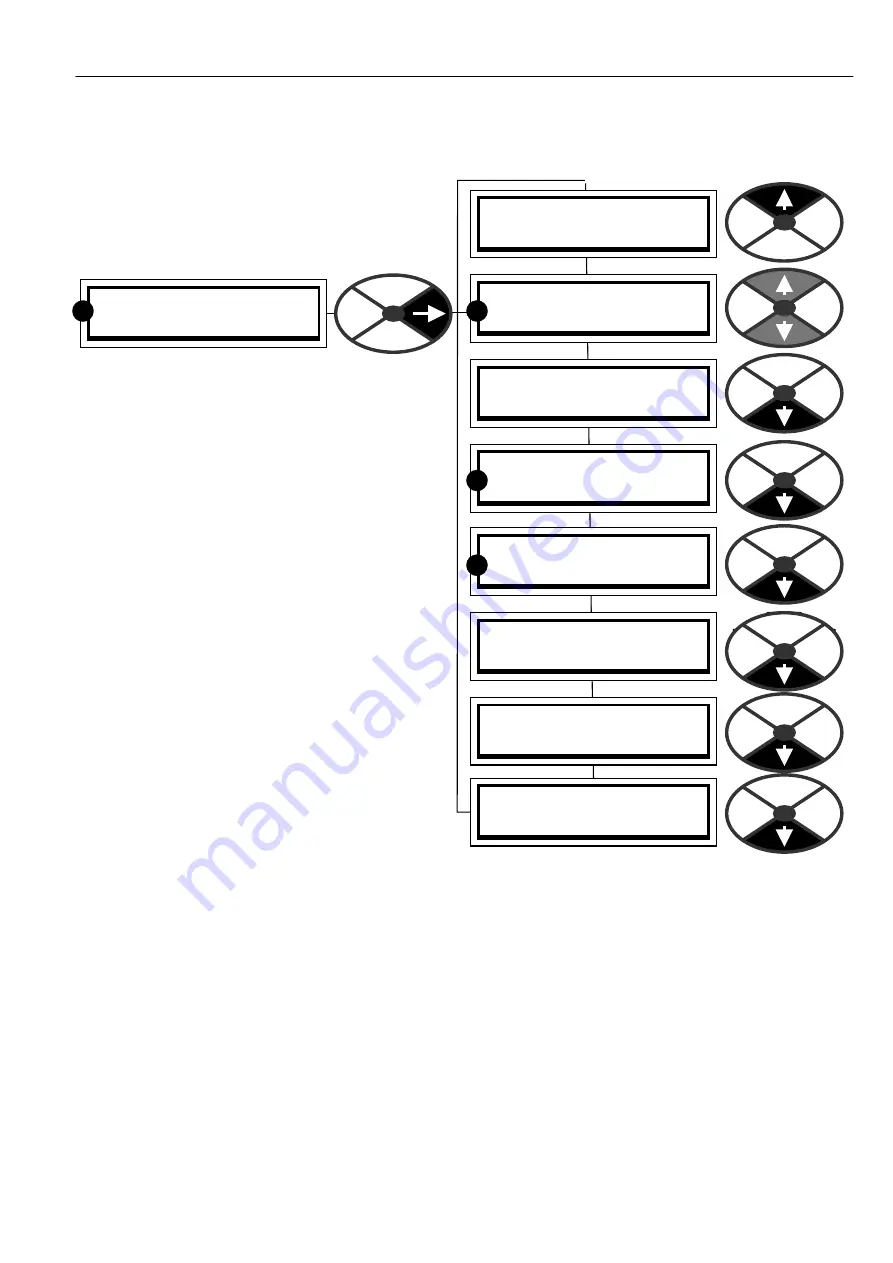

C H A N GE PAR A METERS 2

ZERO IN TERLO C KS 3

R

ZERO IN TERLO C KS 3

SPINDLE ORIEN T A TE 4

ZERO IN TERLO C KS 3

1 1 5)S T A NDSTILL ENBL

ZERO IN TERLO C KS 3

1 1 6)ZERO REF ST ART

ZERO IN TERLO C KS 3

1 1 7)ZERO IN TLK SPD %

ZERO IN TERLO C KS 3

1 1 8)ZERO IN TLK C UR %

ZERO IN TERLO C KS 3

1 1 9)A T ZERO REF FL A G

ZERO IN TERLO C KS 3

1 2 0)A T ZERO SPD FL A G

R

R

R

ZERO IN TERLO C KS 3

1 2 1)A T S T A NDSTILL

Summary of Contents for PLX

Page 2: ...2 Contents ...

Page 202: ......