4 2

Bas

i

c app

li

cat

i

on

4.5 CONT

R

O

L

ENG

I

NEE

R

I

NG COMM

I

SS

I

ON

I

NG

PR

OCEDU

R

ES

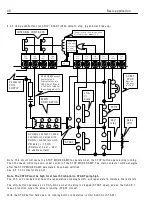

Before app

l

y

i

ng po w er to the L1/2/3 term

i

na

l

s for the f

i

rst t

i

me,

i

t

i

s recommended that a h

i

gh w attage

res

i

stor of bet w een 4 and 4 0 O hms

(

E.g.

a

1 Kw f

ir

e

b

a

r

)

i

s

i

nserted

i

n ser

i

es w

i

th the armature.

Th

i

s w

ill

li

m

i

t any potent

i

a

ll

y destruct

i

ve current and prevent poss

i

b

l

e thyr

i

stor damage.

(A typ

i

ca

l

examp

l

e of the cause of fau

l

t current

i

s the

i

ncorrect phas

i

ng of the EL/1/2/3 term

i

na

l

s w

i

th

respect to L1/2/3. W

i

thout the correct sem

i

-conductor fuses th

i

s may resu

l

t

i

n thyr

i

stor damage on the

app

li

cat

i

on of the start command).

(Note. The f

i

re bar w

ill

be removed pr

i

or to perform

i

ng the A U T O T UNE procedure as descr

i

bed

l

ater).

1) For systems us

i

ng f

i

e

l

d w eaken

i

ng, start w

i

th the un

i

t ca

li

brated for armature vo

l

tage feedback f

i

rst

i

n

order to ver

i

fy norma

l

operat

i

on up to base speed. Then

i

ntroduce f

i

e

l

d w eaken

i

ng on

l

y after carefu

l

ca

li

brat

i

on, and s w

i

tch

i

ng to e

i

ther tacho or encoder feedback.

2) For systems emp

l

oy

i

ng torque contro

l

i

t

i

s recommended to set up

i

n bas

i

c speed mode f

i

rst

i

n order to

estab

li

sh correct speed

l

oop funct

i

on

i

ng and ca

li

brat

i

on.

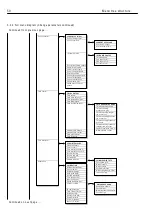

4.5.1 Q u

i

ck start ca

li

brat

i

on

Assum

i

ng that the dr

i

ve un

i

t

i

s correct

l

y

i

nsta

ll

ed and the motor and

l

oad are safe and ready to be rotated,

then the next task

i

s to ca

li

brate the dr

i

ve to su

i

t the supp

l

y and the motor.

The PL/X ser

i

es has a method of ca

li

brat

i

on w h

i

ch avo

i

ds the need to so

l

der res

i

stors and set s w

i

tches. A

ll

the fundamenta

l

dr

i

ve sca

li

ng parameters can be programmed v

i

a the on board d

i

sp

l

ay and menu keys.

Once the

i

n

i

t

i

a

l

ca

li

brat

i

on menu

i

s comp

l

eted the chosen

li

m

i

ts may be saved and w

ill

rema

i

n una

l

tered

un

l

ess you w

i

sh to re-ca

li

brate. There

i

s a

l

so the cho

i

ce of us

i

ng a pass w ord to prevent unauthor

i

sed re-

ca

li

brat

i

on.

The un

i

t automat

i

ca

ll

y kno w s the mode

l

armature current rat

i

ngs and w

ill

prevent sett

i

ng of armature current

i

n excess of the mode

l

rat

i

ng.

See 1 3.1 3.4 DRIV E PERS O N ALIT Y / Armature current burden res

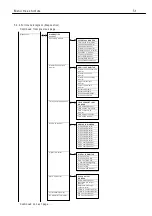

The parameters that w

ill

be se

l

ected for qu

i

ck start ca

li

brat

i

on are as fo

ll

o w s

See 6.1 C H A N GE P AR A METERS / C ALIBR A TIO N for a fu

ll

exp

l

anat

i

on of these parameters

Parameter

Range

Factory defau

l

t

Entered Un

i

ts

2)RA TED A RM A T URE A MPS

3 3 – 1 0 0 % of un

i

t rat

i

ng

3 3 %

A mps

3)C URREN T LIMIT %

0 – 1 5 0 % of un

i

t rat

i

ng

1 5 0 %

%

4)RA TED FIELD A MPS

0.1 A – 1 0 0 % of un

i

t rat

i

ng

2 5 %

A mps

5)B A SE RA TED RPM

0 - 6 0 0 0

1 5 0 0

Revs per m

i

nute of motor at

max

i

mum armature vo

l

ts

6)DESIRED M A X RPM

0 - 6 0 0 0

1 5 0 0

Max revs per m

i

nute of motor at

your des

i

red max speed

9)SPEED FEEDB A C K T YPE

Armature vo

l

tage (se

l

ect th

i

s one)

p

l

us 4 other cho

i

ces

Armature

vo

l

tage

Armature vo

l

tage

1 8)RA TED A RM V OLTS

0 – 1 0 0 0.0 V OLTS D C

4 6 0

V o

l

ts

1 9)EL1/2/3 RA TED A C

0 to 1 0 0 0.0

4 1 5 V

V o

l

ts A C

By se

l

ect

i

ng Armature V o

l

tage a qu

i

ck start

i

s more eas

il

y ach

i

eved.

1) The speed feedback

i

s a

l

w ays present, and

i

n the correct po

l

ar

i

ty.

2) The motor and/or

l

oad can be seen to be rotat

i

ng correct

l

y and at approx

i

mate

l

y the correct speed.

3) If a tachogenerator or encoder

i

s f

i

tted then

i

t can be checked for the correct po

l

ar

i

ty and output

l

eve

l

s

pr

i

or to

i

nc

l

ud

i

ng

i

t

i

n the feedback

l

oop.

4) O ther parameters such as ramp rates and stopp

i

ng modes can be checked and or set before

proceed

i

ng to f

i

na

l

accurate ca

li

brat

i

on.

5) The system may need pre-test pr

i

or to sh

i

pp

i

ng and no tachogenerator

i

s ava

il

ab

l

e. For th

i

s qu

i

ck start

procedure

i

t

i

s on

l

y necessary to set the above parameters.

Summary of Contents for PLX

Page 2: ...2 Contents ...

Page 202: ......