5 8

C H A N GE PARA METERS

C H A N GE PAR A METERS menu

There are a very

l

arge number of parameters that

can be a

l

tered by the user. A

ll

the a

l

terab

l

e

parameters have a factory defau

l

t sett

i

ng that

i

n

most cases w

ill

prov

i

de a perfect

l

y w orkab

l

e

so

l

ut

i

on and w

ill

not need a

l

ter

i

ng.

One c

l

ass of parameters that w

ill

need sett

i

ng

ho w ever

i

s the C ALIBR A TIO N va

l

ues. These are

spec

i

a

l

because they are used to set the max

i

mum

rat

i

ngs for the motor and dr

i

ve.

The abso

l

ute max

i

mum ava

il

ab

l

e armature current

of any part

i

cu

l

ar mode

l

w

ill

not norma

ll

y exceed the

C ALIBRA TIO N menu sett

i

ng. If the contro

l

card

i

s

transferred to a d

i

fferent po w er chass

i

s

i

t w

ill

automat

i

ca

ll

y

i

nterrogate the chass

i

s to determ

i

ne

the frame s

i

ze. The user must make sure that

i

f the

armature burden res

i

stor va

l

ue

i

s d

i

fferent, then the

ne w va

l

ue

i

s entered

i

nto the un

i

t. See 1 3.1 3.4

DRIV E PERS O N ALIT Y / Armature current burden

Th

i

s a

ll

o w s o w ners of

l

arge numbers of dr

i

ves to

ho

l

d m

i

n

i

ma

l

spares.

Somet

i

mes

i

t

i

s usefu

l

to return a un

i

t to

i

ts defau

l

t

parameter cond

i

t

i

on. E.g. a tr

i

a

l

conf

i

gurat

i

on may

prove to be un w orkab

l

e and

i

t

i

s eas

i

er to start

aga

i

n. If a

ll

4 keys are he

l

d do w n dur

i

ng the

app

li

cat

i

on of the contro

l

supp

l

y, then the dr

i

ve w

ill

automat

i

ca

ll

y refer to the defau

l

t parameters and

i

nterna

l

connect

i

ons.

Ho w ever parameters that are used to match the motor to the dr

i

ve are not affected by restor

i

ng the defau

l

ts.

Th

i

s

i

nc

l

udes a

ll

thos

e

i

n th

e

CA

L

I

B

R

AT

I

ON m

e

nu

a

nd 100

)

F

I

E

L

D VO

L

TS O

P

%,

(

fo

r

MOTO

R

1

a

nd MOTO

R

2

)

a

nd 680

)

I

a

r

m BU

R

DEN OHMS. Th

e

s

e

p

a

r

a

m

e

t

e

r

s

r

e

m

a

i

n

a

s p

r

e

v

i

ous

l

y

ca

li

b

r

a

t

e

d to p

r

e

v

e

nt

acc

i

d

e

nt

a

l

d

e

-

ca

li

b

r

a

t

i

on wh

e

n

r

e

sto

ri

ng d

e

f

a

u

l

ts

. See 5.1.3 Restor

See a

l

so 1 3.1 3.2 DRIV E PERS O N ALIT Y / Rec

pe page PIN 6 7 7, for deta

il

s of 2 and 3 key reset operat

i

on.

Th

i

s feature a

ll

o w s for 3 tota

l

i

nstrument rec

i

pes to be stored and retr

i

eved. W ARNIN G. Rec

i

pe page 2 and 3

each have the

i

r o w n set of ca

li

brat

i

on parameters, so be carefu

l

to check them a

ll

pr

i

or to runn

i

ng.

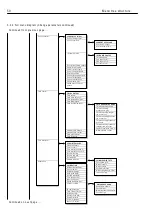

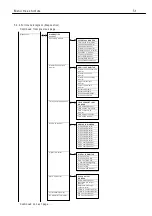

EN TRY MENU LE V EL 1

C H A N GE PAR A METERS 2

C H A N GE PAR A METERS 2

C ALIBRA TIO N 3

C H A N GE PAR A METERS 2

RUN M O DE R A MPS 3

C H A N GE PAR A METERS 2

J O G CRA WL SL A C K 3

C H A N GE PAR A METERS 2

M O T ORISED PO T RA MP 3

C H A N GE PAR A METERS 2

ST OP M O DE RA MPS 3

C H A N GE PAR A METERS 2

SPEED REF SU M MER 3

C H A N GE PAR A METERS 2

SPEED C O N TROL 3

C H A N GE PAR A METERS 2

C URREN T C O N TROL 3

C H A N GE PAR A METERS 2

FIELD C O N TROL 3

C H A N GE PAR A METERS 2

ZERO IN TERLO C KS 3

R

R

R

R

R

R

R

R

R

Summary of Contents for PLX

Page 2: ...2 Contents ...

Page 202: ......