Bareknuckle Welterweight - Airless Paint Sprayer

OPERATING INSTRUCTIONS & SAFETY MANUAL

Bareknuckle Welterweight - Airless Paint Sprayer

OPERATING INSTRUCTIONS & SAFETY MANUAL

|

8 |

9

Clean Sprayer immediately to prevent permanent damage.

Clean Sprayer immediately to prevent permanent damage.

9

9

9

9

9

9

9

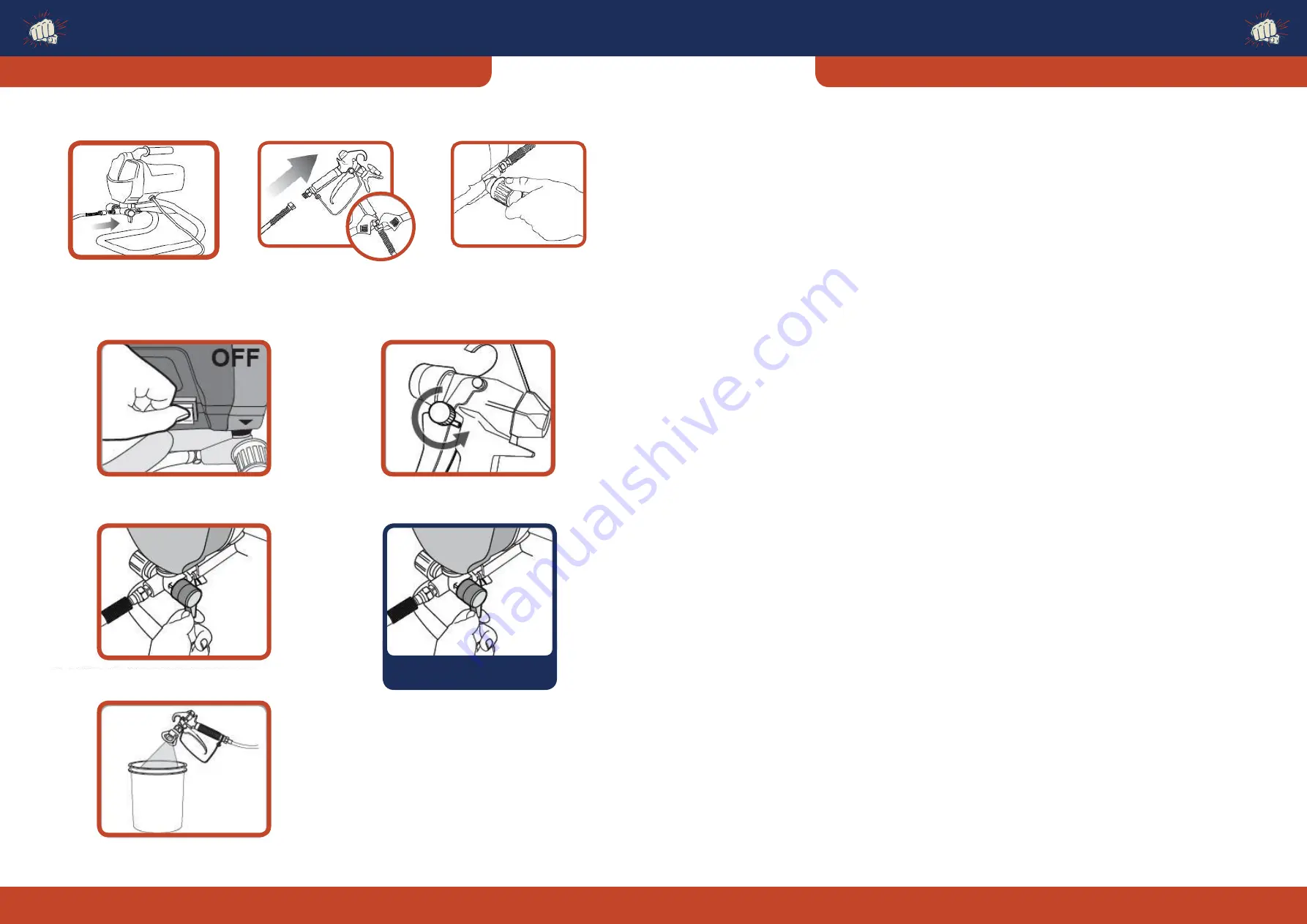

TO RELIEVE SPRAYER PRESSURE

SETUP

NOTE: Remove or cover objects that you want to protect from overspray (paint mist).

1. Attach Paint Hose to Paint Hose

Outlet and tighten with wrench.

1. Turn Power Switch off and unplug unit

from outlet

2. Switch Prime/Spray switch to Prime mode.

Note: Always set to Prime mode

between uses.

3. Point gun into paint pail and activate

Sprayer Trigger to relieve pressure.

4. Turn Trigger Knob to Locking poistion.

2. Attach Paint Hose to Paint Gun

and tighten with two wrenches.

3. Turn Pressure Control Knob to

Low Pressure Spray setting.

Bareknuckle Welterweight - Airless Paint Sprayer

OPERATING INSTRUCTIONS & SAFETY MANUAL

8 |

9

BEFORE STARTING

1)

CHECK

all fittings and connections in the pump system,

hose, and gun to ensure that they are tight.

CHECK

to ensure that there is a spray tip in the gun,

and that the tip is the correct size for the coating you

are to spray. (There are various tips available, for each

type of coating or configuration.)

2)

MAKE SURE

the power source is securely grounded and

match the motor rating of your sprayer.

3) New spray: Oil is used by the factory for testing and

protection. It is necessary to flush unit before spraying.

Clean the pump with warm soapy water. Make sure

the hydraulic oil in the pump is clean and sufficient in

volume then begin the following procedure

1. Remove spray tip from gun

2. Put the input hose and pressure relief tube into the

bucket with some water,

3. Turn on the motor and push the pressure valve

upright. In a few seconds, water will begin to flow

up through the tube and flow out from outlet valve,

tighten the outlet valve deasil, then tighten the

pressure valve deasil.

4. When the pressure reaches up to around 207bar,

check if there is any leakage on the outlet hose, if it’s

leaking, Please check. Don’t stop or deflect leaks with

your hand, body, glove or rag.

5. If it doesn’t leak, open the spray gun and test spray.

Clean the oil in pump. Change the soapy water and

use clean water when the spray is clean.

6. Turn off power, Continue to spray until there is no

more water.

7. Unlock trigger lock. Put the pressure valve upright, till

no soapy water in pump.

Whenever instructed to relieve pressure, Stop spraying,

Check or service equipment or install or clean spray tip.

1. Engage trigger safety lock on gun. Turn Off power

and turn sprayer pressure control to lowest pressure

setting.

2. Hold gun against side of flushing pail. Trigger gun

into pail to relieve pressure.

3. Turn off pump and release fluid pressure by turning

the pressure relief prime valve located on the side of

the pump down.

OPERATING INSTRUCTIONS

PRESSURE RELEASE PROCEDURE

9

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.