10

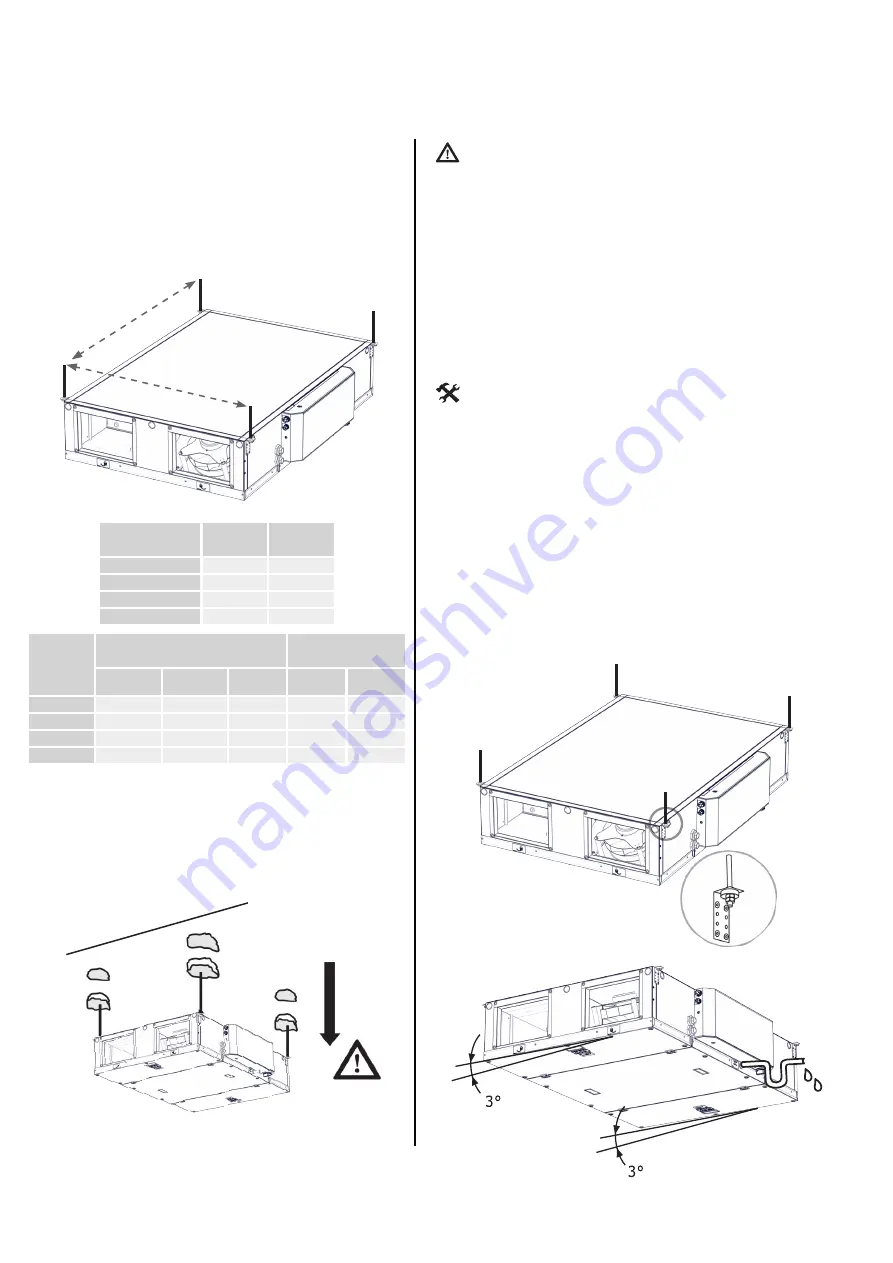

6.1-3 Hanging the unit

For location of the anchorage points, use the drill-

ing template listed below.

The units are equipped with mounting brackets

which should be used in conjunction with threaded

drop rods ZTZ-M8/1.0 or equivalent to facilitate

levering and leveling.

•

Due to the weight of the unit, it is necessary to

use an appropriate lifting device when assem

-

bling (e. g. a forklift, scissor lift, etc...)

•

It’s recommended that the unit is installed into

position before making connections to duct

and pipe work or electrical connections.

•

Depending on the type of building structure

there can be a number of ways of attaching

the suspension system, such as drilled-in fix

-

ings, clamps and clips, wedge nuts, etc.. En

-

sure whatever system is utilized it has suffi

-

cient strength to support the unit.

•

4-6 M8 check nuts (according to the unit type)

•

4-6 stud bolts

•

4-6 dowels of a suitable type and dimension

(according to the ceiling material and the unit

weight)

•

Driller with drills of a suitable type and dimen

-

sion

•

Tongs and nut wrenches

Place the unit horizontally and then incline it by 3°

by adjusting the nuts on the drop rods so that the

condensate drains into the outlet connection on

the access side of the unit.

ATTENTION!

YOU WILL NEED

6. INSTALLATION

Establish the weight of each unit and make sure

that ceiling will be adequate to support up to four

times the weight of the unit.

Drill the holes in the ceiling, try the strength of its

material and attach the unit by the side brackets

using the hanging rods ZTZ-M8/1.0 or equivalent.

A

B

Type

A

B

HRFL2-040

700

1120

HRFL2-070

1000

1330

HRFL2-150

1300

1630

HRFL2-200

1630

1930

Type

Weight of unit (kg)

Weight of accesso-

ries (kg)

Without

reheating

With electric

reheating

With water

reheating

WCO

mod-

ule

DX module

HRFL2-040

70

75

75

25.5

24

HRFL2-070

90

95

95

32

30

HRFL2-150

165

170

170

37

35

HRFL2-200

240

245

245

43

40