B1: DIXELL OPERATING INSTRUCTIONS

dIXEL

Operating instructions

1592002701

1592002701 XH240L-V GB r1.0 12.01.2004 *

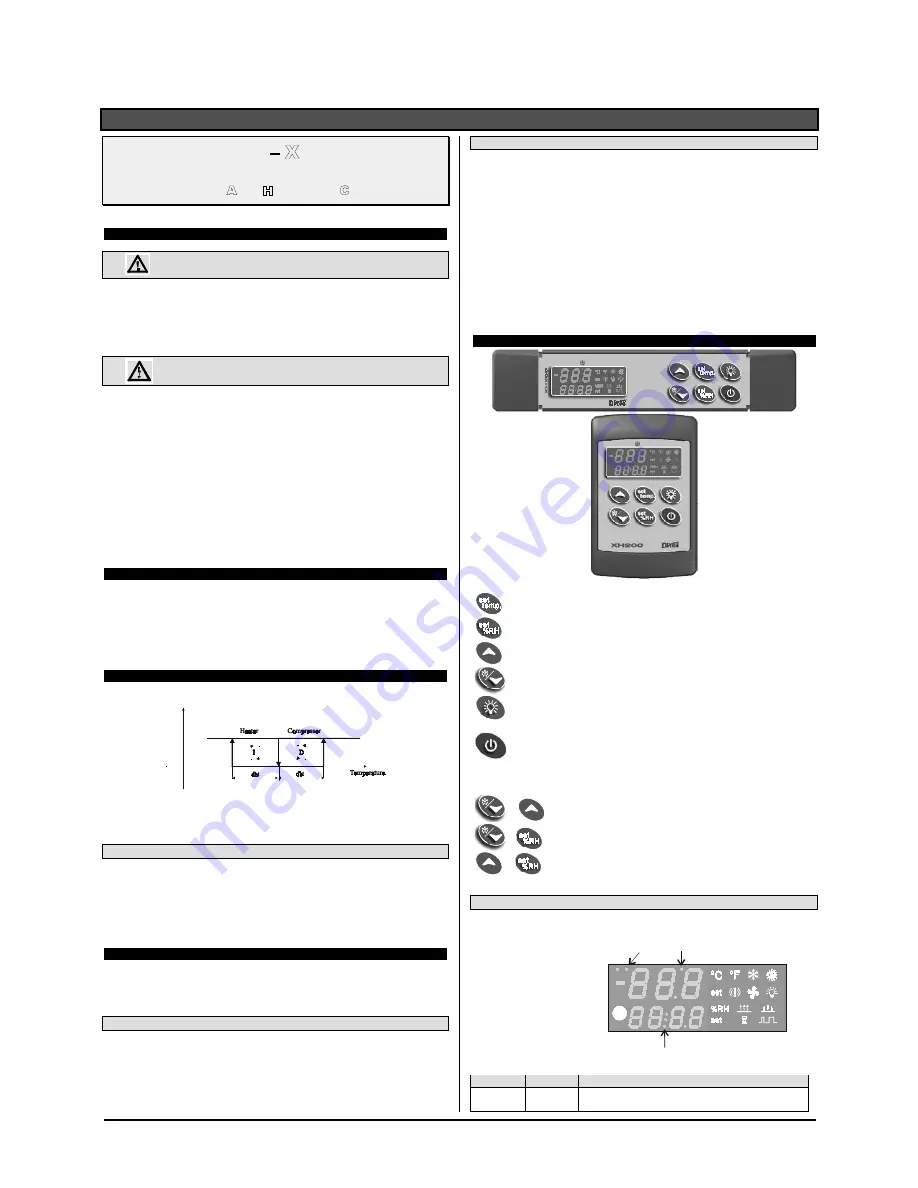

XH240L - XH240V

1/4

XH240L – XH240V

TEMPERATURE AND HUMIDITY CONTROLLER

1.

GENERAL WARNING

1.1

PLEASE READ BEFORE USING THIS MANUAL

x

This manual is part of the product and should be kept near the instrument for easy and

quick reference.

x

The instrument shall not be used for purposes different from those described hereunder. It

cannot be used as a safety device.

x

Check the application limits before proceeding.

1.2

SAFETY PRECAUTIONS

x

Check the supply voltage is correct before connecting the instrument.

x

Do not expose to water or moisture: use the controller only within the operating limits

avoiding sudden temperature changes with high atmospheric humidity to prevent formation

of condensation

x

Warning: disconnect all electrical connections before any kind of maintenance.

x

Fit the probe where it is not accessible by the End User. The instrument must not be

opened.

x

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell

s.r.l.” (see address) with a detailed description of the fault.

x

Consider the maximum current which can be applied to each relay (see Technical Data).

x

Ensure that the wires for probes, loads and the power supply are separated and far enough

from each other, without crossing or intertwining.

x

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in

parallel with inductive loads could be useful.

2.

GENERAL DESCRIPTION

The

XH240L,

38x185

format, and the

XH240V,

100x64

format, are microprocessor controllers,

suitable for applications on medium temperature refrigerating units. They control both humidity

and temperature. They have 4 output relays to control compressor, heating elements , fan and

humidifier. They have 2 analogue inputs: one for temperature control, the other one for humidity.

There is one digital input (free contact) configurable by parameter. An output allows the user to

programme the parameter list with the

“Hot Key”.

3.

TEMPERATURE REGULATION

The temperature regulation is performed through neutral zone using compressor and heater

output relays.

Set point

OFF

ON

•

Heating

output: CUT IN is “SET_TEMP-dbt”, CUT OUT is when the temperature reaches the

set point.

•

Compressor

output CUT IN is “ SET_TEMP +dbt”, CUT OUT is when the temperature

reaches the set point.

3.1

DEFROST

Defrost is performed through a simple stop of the compressor. Parameter “

IdF

” controls the

interval between defrost cycles, while its length is controlled by parameter “

MdF

”.

To

disable

the defrost set the

MdF

parameter to

zero

Humidity regulation during a defrost depends on the

Hud

parameter.

With

Hud=no

humidity regulation is disabled.

Con

Hud=yES

humidity regulation is performed also during a defrost.

4.

HUMIDITY REGULATION

The humidity regulation is performed through neutral zone, by humidifying dehumidifying

actions.

Humidity control can be disabled setting the SET_RH to “nu” value. In this case only the

temperature control is perform.

4.1

HUMIDIFYING ACTION

The humidifying action is done enabling the humidifier relay when the humidity is lower than the

“SET_RH-dbH” value.

The relay is switch off when humidity reaches the set values.

4.2

DEHUMIDIFYING ACTION

The dehumidifying action is performed enabling the heating and compressor outputs together

when humidity is higher than dbH value.

Outputs are disabled when humidity comes back to the SET_RH value.

4.2.1 Relation between cooling, heating and dehumidifying

1.

If is simultaneously present a request of cooling (temp>Sdbt) and

dehumidifying (RH > dbH): the cooling action has the priority over the

dehumidifying action: only the compressor relay is energised till the SET_TEMP is

reached at this point also the heating relay is enabled.

2.

If is simultaneously present a request of heating (temp< SET_TEMP-dbt) and

dehumidifying (RH > dbH): the dehumidifying action has the priority over the

heating action: both the compressor and the heating relays are energised till the humidity

set is reached at this point only the heating relay is enabled.

5.

THE DISPLAY

To display and modify target temperature set point. (SET_TEMP)

To display and modify target humidity set point (SET_RH); in programming mode it

selects a parameter or confirm an operation.

In programming mode it browses the parameter codes or increases the displayed

value.

In programming mode it browses the parameter codes or decreases the displayed

value. By holding it pressed for 3s the defrost is started

Switch ON and OFF the light, if present

Switch ON and OFF the instrument.

KEY COMBINATIONS

+

To lock and unlock the keyboard

+

To enter the programming mode.

+

To exit the programming mode.

5.1

ICONS AND SYMBOLS

Each LED function is described in the following table.

LED2

LED3

LED4

Temperature Display

Humidity Display

LED

MODE

FUNCTION

Led 4

ON

- Instrument in stand by.

- In “Pr2” indicates that the parameter is also present in “Pr1”.

Summary of Contents for AGB

Page 2: ...ii...

Page 22: ...A1 WIRING DIAGRAM...