Operation and Maintenance Manual

Last Updated - 08/31/2016

495B ML TM (S)

18

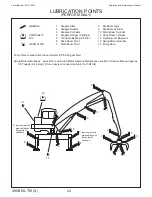

Preventive maintenance is really just a simple matter of common sense. If you keep any piece of mechanical

equipment clean and properly lubricated, and promptly replace any worn or damaged parts, you are going to "prevent"

deterioration and promote long life and safe, productive service. The only other requisite to such a program is the

regular scheduling of such maintenance.

Obviously, when you are operating under severe job conditions, such as a dusty job site, in extreme heat or cold, a

long operating day, or extremely heavy loads, the recommended intervals in the schedule should be shortened.

The suggested schedule on the following page is designed to be just a reminder of what should be done. For detailed

instructions on each item, consult the Table of Contents for where each is located in this manual.

AFTER THE FIRST 100 HOURS OF OPERATION OF A NEW MACHINE

A new machine needs a special maintenance procedure after the first 100 hours of operation.

1. Do a complete inspection of the loader. Rectify any problems, replace any damaged parts.

2. Check torque (retorque if necessary):

- Turntable Bearing Mounting Bolts

- Mounting Bolts/Nuts on major machine components (gearboxes, motors, pumps, booms,

attachment, turntable bearing, lower assembly, tires, etc.)

3. Check torque of loader mounting bolts. Retorque if necessary.

4. Change all filter elements.

Resume the normal maintenance intervals after this. See the Service Schedule for more information.

SPECIAL NEW-MACHINE INSTRUCTIONS

PREVENTIVE MAINTENANCE

Instructions are necessary before doing service on loader. See

warnings and instructions both at the beginning and throughout

this manual. After doing service or making repairs or adjustments

always check function of loader.

Safety glasses or goggles are always needed for eye protection

from electric arcs, from shorts or welding, battery acid, compressed

springs, fluids under pressure, and flying debris or loose material

when engines are running or tools are used. Use eye protection

approved for type of welding. Failure to obey warnings can cause

death, severe injury or property damage.

Summary of Contents for 495B SD

Page 3: ...Introduction...

Page 7: ......

Page 16: ...Maintenance...

Page 19: ...Operation and Maintenance Manual 495B ML TM S 19 Last Updated 08 31 2016 SERVICE SCHEDULE...

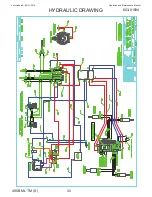

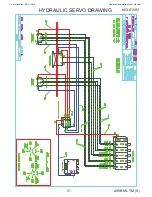

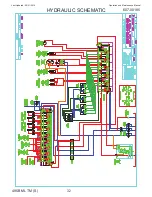

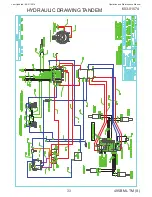

Page 29: ...Hydraulic...

Page 57: ...Electrical...

Page 58: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 58 ELECTRICAL SCHEMATIC...

Page 78: ...Maintenance...

Page 88: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 88 Structural...

Page 95: ...Trouble Shooting...