Operation and Maintenance Manual

Last Updated - 08/31/2016

495B ML TM (S)

80

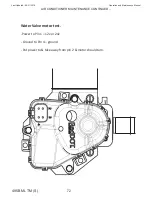

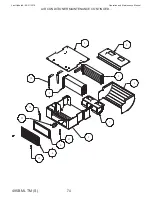

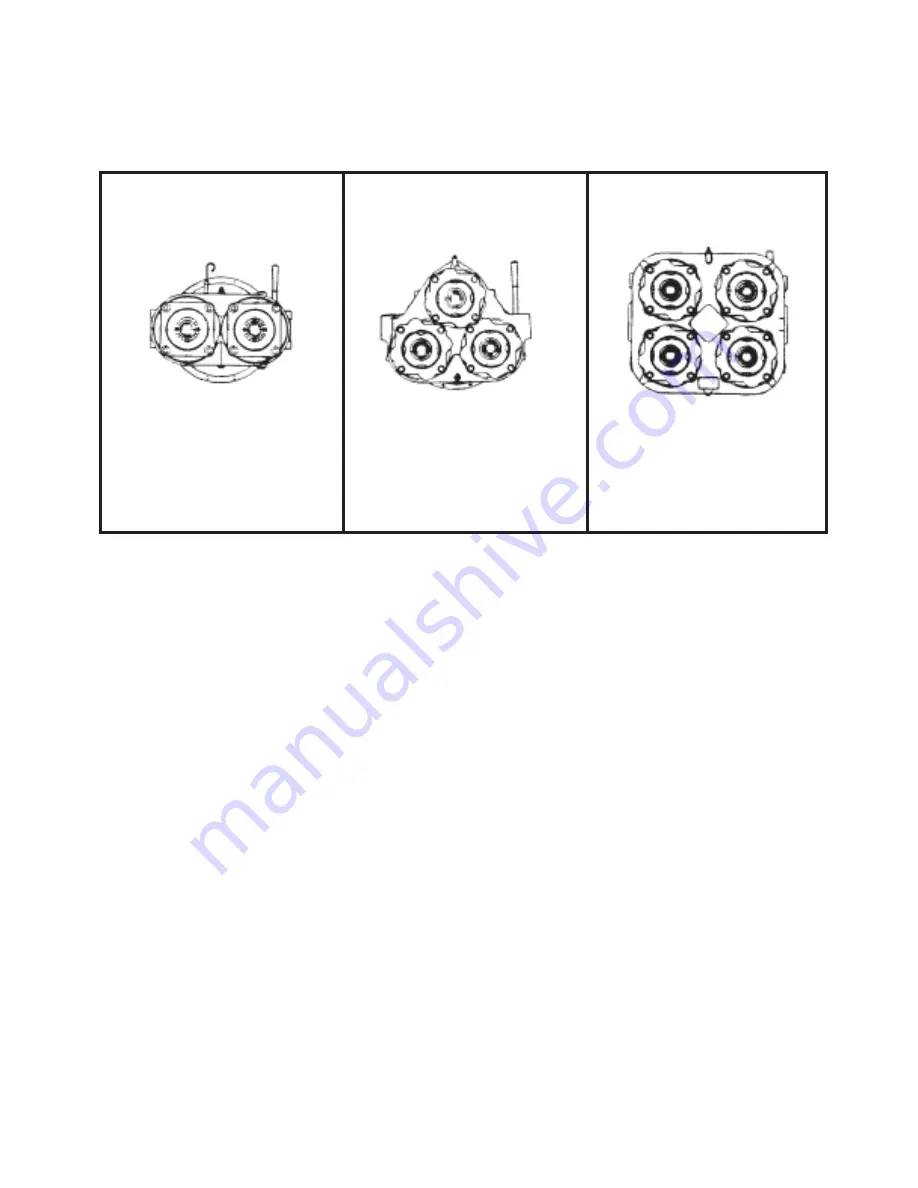

TWO, THREE AND FOUR PAD PUMP DRIVES

2 PAD PUMP DRIVE

3 PAD PUMP DRIVE

4 PAD PUMP DRIVE

Figure 1

LUBRICANT RECOMMENDATIONS AND FLUID CHANGING PROCEDURES

Lubricant Type:

EP 80-90 gear fluid (except for direct drive models).

Lubricant Grade:

Weather Temperature

Below -10 degrees F (-23 degrees C) = Use 75 W.

Above -10 degrees F and up to 100 degrees F (37.8 degrees C) = Use 80 W/90.

Above 100 degrees F (37.8 degrees C) = Use 85 W/140.

It is recommended that the fluid level be checked daily, at the same time checking for fluid leaks.

Because the lubricant system is the heart of the unit, it is especially important that the fluid be kept clean.

The following procedures should be followed:

1. Stop engine before checking or adding fluid.

2. Check unit for operational warning tags. Heed all warnings.

3. Clean around fluid fill before checking or adding fluid.

4. Change the fluid after every 400 hours of operation. Also, the fluid in the unit should be changed whenever

the

fluid level shows traces of dirt or effects of high temperature, evidenced by discoloration or strong odor.

5. Drain the fluid while the unit is still warm, examining for contamination or metal particles.

(FOR FUNK PUMP DRIVES)

PUMP DRIVE MAINTENANCE

Summary of Contents for 495B SD

Page 3: ...Introduction...

Page 7: ......

Page 16: ...Maintenance...

Page 19: ...Operation and Maintenance Manual 495B ML TM S 19 Last Updated 08 31 2016 SERVICE SCHEDULE...

Page 29: ...Hydraulic...

Page 57: ...Electrical...

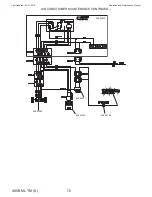

Page 58: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 58 ELECTRICAL SCHEMATIC...

Page 78: ...Maintenance...

Page 88: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 88 Structural...

Page 95: ...Trouble Shooting...