page 36

595 ML CRL (S)

800-00177

HYDRAULIC FILTER MAINTENANCE

THE DRAIN FILTER

(See Figure 2)

This filter is mounted in the shrouding enclosure. The drain filter (565-00061) contains a replaceable filter element which

simply unscrews from the filter head.

CAUTION

These filter elements are not re-usable.

ELEMENT REPLACEMENT PROCEDURE

1.

Remove old element by unscrewing it from filter head.

2.

Remove used gasket from groove in filter head.

3.

Take new gasket from inside new element and install in groove in filter head.

4.

Apply oil to new gasket.

NOTE: On a new machine the filter elements must be changed after the first 100 hours of

operating time and then every 400 hours after that.

THE RETURN FILTER

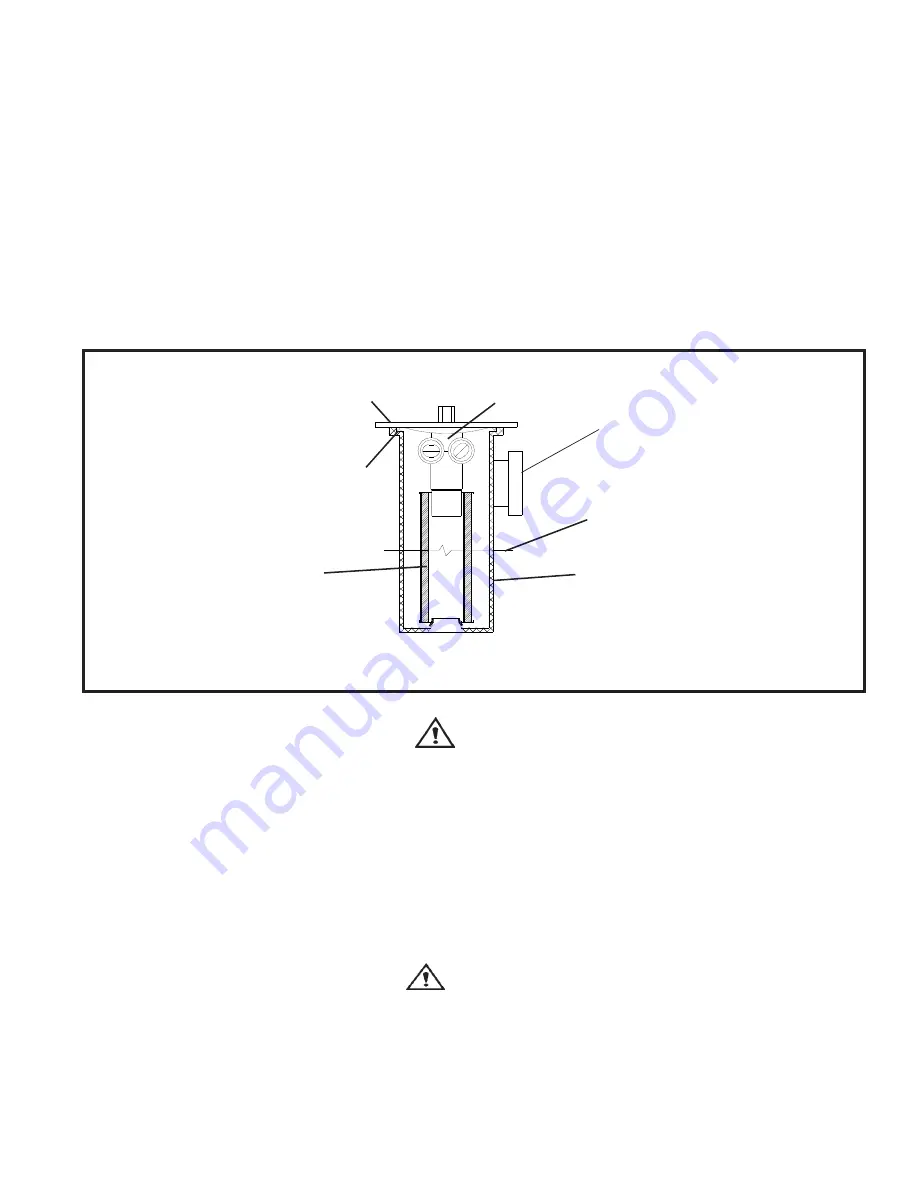

(See Figure 1)

The Return Filters (565-00116) are welded into the top of the hydraulic oil reservoir.

The filter heads must be unbolted, twisted, and lifted off to reveal the filter element which can then be removed and

replaced.

FILTER HOUSING

(welded to top plate

of Hydraulic Oil

Reservoir)

TOP PLATE OF

HYDRUALIC OIL

RESERVOIR

FILTER HEAD AND

BYPASS

BOLTS

O-RING

FILTER

ELEMENT

Figure 1

CAUTION

When maintaining the hydraulic system, keep all parts clean and remove all dirt

from the area before you begin disassembly. Use caps and plugs to keep dirt out of

tubelines and openings.

RETURN LINE INLET

(attaches to manifold)

Summary of Contents for 595ML

Page 3: ...page3 595 ML CRL S 800 00177 Introduction Marker...

Page 16: ...page16 595 ML CRL S 800 00177 Maintenance A PREVENTIVE MAINTENANCE Maintenance...

Page 27: ...page27 595 ML CRL S 800 00177 Maintenance B HYDRAULIC SYSTEM...

Page 33: ...page33 595 ML CRL S 800 00177 HYDRAULIC PRESSURE ADJUSTMENT CONTINUED 558 01699...

Page 44: ...page44 595 ML CRL S 800 00177 Maintenance C ELECTRICAL SYSTEM MAINTENANCE...

Page 67: ...page67 595 ML CRL S 800 00177 Maintenance D POWER UNIT MAINTENANCE...

Page 77: ...page77 595 ML CRL S 800 00177 Structural E STRUCTURAL MAINTENANCE...

Page 84: ...page84 595 ML CRL S 800 00177 Trouble Shooting Marker Marker Marker...