page 54

595 ML CRL (S)

800-00177

AIR CONDITIONER MAINTENANCE CONTINUED...

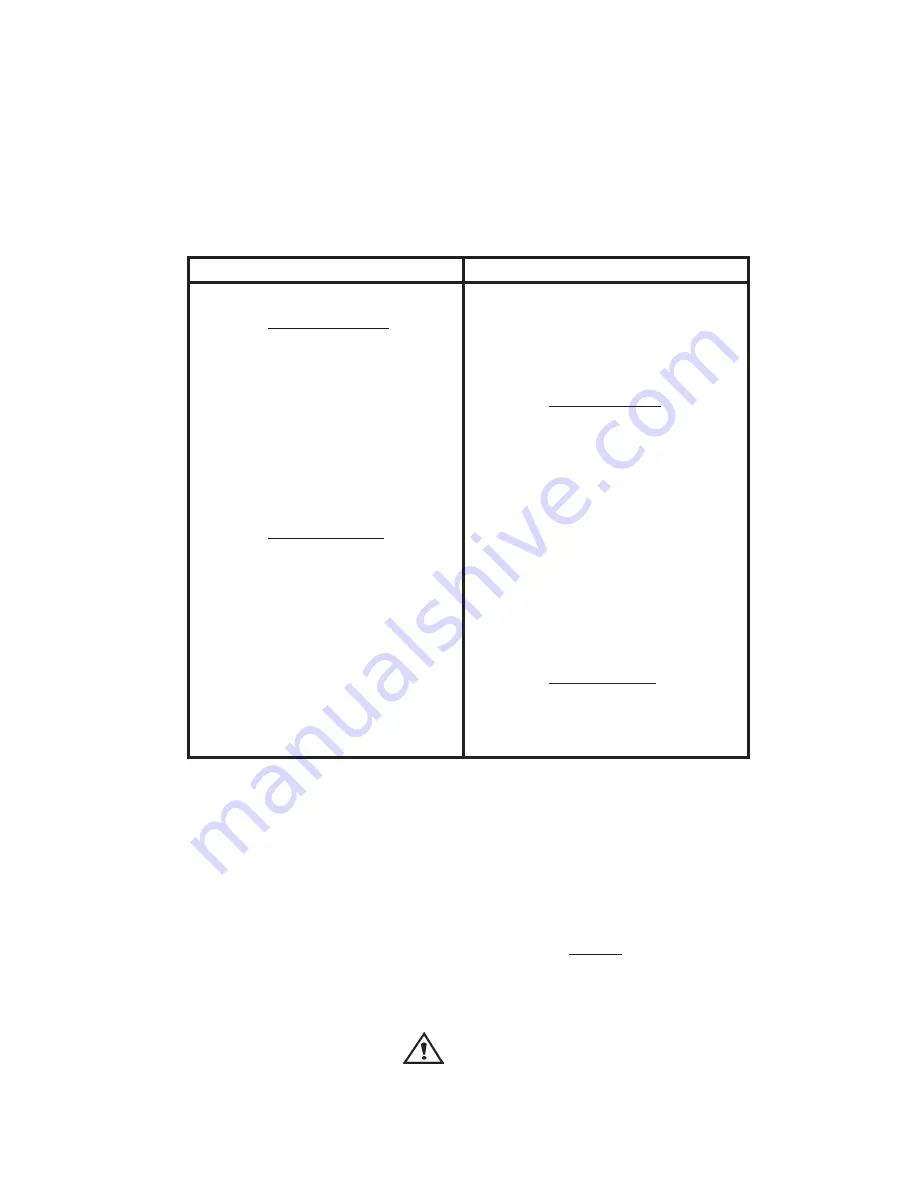

130 F. condenser temp. = 200 PSIG*

* based on 30 MPH air flow.

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

45

50

55

60

65

70

75

80

85

90

91

92

All values rounded two places.

C

O

N

D

E

N

S

E

R

R

A

N

G

E

15.69

17.04

18.43

19.87

21.35

22.88

24.47

26.10

27.79

29.52

31.32

33.17

35.07

37.03

39.05

40.09

45.48

51.27

57.47

64.10

71.19

78.75

86.80

95.40

104.40

106.30

108.20

93

94

95

100

102

104

106

108

110

112

114

116

118

120

122

124

126

128

130

135

140

145

150

155

160

165

170

110.20

112.10

114.10

124.30

128.50

132.90

137.30

141.90

146.50

151.30

156.10

161.10

166.10

171.30

176.60

182.00

187.50

193.10

198.90

213.70

229.40

245.80

263.00

281.10

300.10

320.00

340.80

The numbers above represent boiling points for R-134a.

EVAPORATOR

pressures represent gas temperatures

inside the coil and not the coil

surfaces. Add to temperature for coil

air-off temperatures (8 - 10f.)

CONDENSER

temperatures are not ambient

temperatures. Add to ambient

(35 - 40 F.) for proper heat transfer,

then refer to pressure chart.

Example:

90 F. ambient temp.

Conditions will vary for different system configurations.

TEMP F.

PSIG

R-134a Temperature Pressure Chart

E

V

A

P

O

R

A

T

O

R

R

A

N

G

E

TEMP F.

PSIG

CHECKING/ADDING REFRIGERANT

Allow only certified personnel to service the heater/air conditioner system. The chart below shows relative

temperatures and pressures for the system.

Generally, for most Barko machines, 3 pounds of refrigerant is required for the system to operate properly. However,

use the chart below to determine the exact amount.

WARNING

Older air conditioning equipment may contain R-12, a substance which harms public

health and environment by destroying ozone in the upper atmosphere. To remove R-12

from the air conditioning system, use service equipment certified to meet the requirements

of S.A.E. J2209 or J1990.

+40

Summary of Contents for 595ML

Page 3: ...page3 595 ML CRL S 800 00177 Introduction Marker...

Page 16: ...page16 595 ML CRL S 800 00177 Maintenance A PREVENTIVE MAINTENANCE Maintenance...

Page 27: ...page27 595 ML CRL S 800 00177 Maintenance B HYDRAULIC SYSTEM...

Page 33: ...page33 595 ML CRL S 800 00177 HYDRAULIC PRESSURE ADJUSTMENT CONTINUED 558 01699...

Page 44: ...page44 595 ML CRL S 800 00177 Maintenance C ELECTRICAL SYSTEM MAINTENANCE...

Page 67: ...page67 595 ML CRL S 800 00177 Maintenance D POWER UNIT MAINTENANCE...

Page 77: ...page77 595 ML CRL S 800 00177 Structural E STRUCTURAL MAINTENANCE...

Page 84: ...page84 595 ML CRL S 800 00177 Trouble Shooting Marker Marker Marker...