page 72

595 ML CRL (S)

800-00177

SINGLE PAD PUMP DRIVES

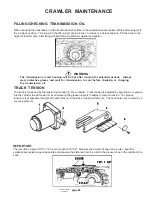

DISCONNECT CLUTCH (OPTIONAL)

If clutch does not pull, heats, or operating lever jumps out, adjustment is required. To adjust clutch, remove hand hole

plate, turn clutch until adjusting lock pin can be reached. Pull adjusting pin out and turn adjusting yoke to right or

clockwise until operating lever requires a distinct pressure to engage. A new clutch requires several adjustments until

friction discs are worn in. See Figure 5.

For cold weather start-up using Disconnect Clutch, see Start-up instructions in Operator's Manual.

Example of a Pump Drive with a Disconnect Clutch

HAND HOLE PLATE

Pull pin in this

direction (it is

spring loaded).

OPERATING LEVER

ADJUSTING PIN

(mounted inside clutch)

ADJUSTING YOKE

Figure 5

Figure 4

If a Disconnect Clutch (optional) is ordered on your machine, the following maintenance must be done.

PUMP DRIVE MAINTENANCE CONTINUED...

This type of Pump Drive (See Figure 4), is mounted to the engine, and is virtually maintenance free.

Summary of Contents for 595ML

Page 3: ...page3 595 ML CRL S 800 00177 Introduction Marker...

Page 16: ...page16 595 ML CRL S 800 00177 Maintenance A PREVENTIVE MAINTENANCE Maintenance...

Page 27: ...page27 595 ML CRL S 800 00177 Maintenance B HYDRAULIC SYSTEM...

Page 33: ...page33 595 ML CRL S 800 00177 HYDRAULIC PRESSURE ADJUSTMENT CONTINUED 558 01699...

Page 44: ...page44 595 ML CRL S 800 00177 Maintenance C ELECTRICAL SYSTEM MAINTENANCE...

Page 67: ...page67 595 ML CRL S 800 00177 Maintenance D POWER UNIT MAINTENANCE...

Page 77: ...page77 595 ML CRL S 800 00177 Structural E STRUCTURAL MAINTENANCE...

Page 84: ...page84 595 ML CRL S 800 00177 Trouble Shooting Marker Marker Marker...