page 73

595 ML CRL (S)

800-00177

AIR CLEANER MAINTENANCE

Proper air cleaner servicing will result in maximum engine protection against the ravages of dust. Proper servicing can

also save you time and money by increasing filter life and dust cleaning efficiency. Two of the most common servicing

problems are:

1.

Over-servicing: New filter elements increase in dust cleaning efficiency as dust builds up on the media.

DON'T BE FOOLED by filter appearance, it should look dirty. By using proper filter restriction measurement

tools you will use the full life of the filter at maximum efficiency.

2.

Improper Servicing: Your engine is highly vulnerable to abrasive dust contaminants during the servicing process.

THE MOST COMMON CAUSE OF ENGINE DAMAGE IS DUE TO CARELESS SERVICE PROCEDURES. By

following the steps shown below and on the next few pages, you can avoid unnecessary dust contamination to the

engine.

The following steps should be taken on a daily basis or more often in severe conditions:

1.

Check to ensure that the air cleaner bonnet is free of leaves, twigs, etc. that are drawn in while the machine is

working. (See Figure 1).

NOTE: This is especially important in the fall months, as the trees shed their leaves.

AIR CLEANER BONNET

Figure 1

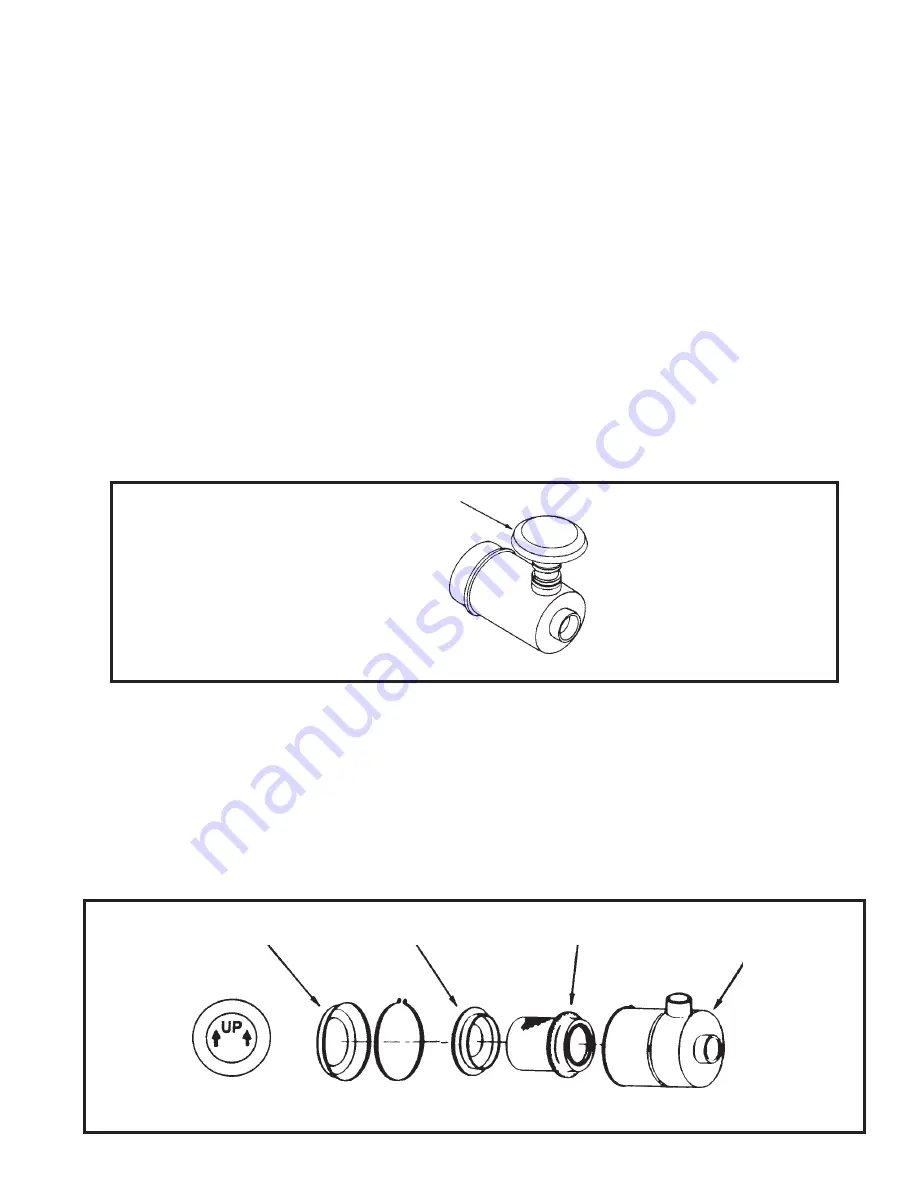

Figure 2

DUST CUP

ARROWS

DUST CUP

BAFFLE

ASSEMBLY

ELEMENT

AIR CLEANER

BODY

2.

Empty the pre-cleaner dust cup. Frequency of dust cup service will vary with dust conditions. See Emptying The

Dust Cup.

3.

Check the restriction indicator daily. When indicated, change the element. See Checking Air Cleaner

Restriction.

EMPTYING THE DUST CUP

Check the dust cup daily for dust build-up. When reinstalling the dust cup, make sure it seals 360 degrees around the

air cleaner body and the directional arrows are pointed in the UP position. See Figure 2.

Summary of Contents for 595ML

Page 3: ...page3 595 ML CRL S 800 00177 Introduction Marker...

Page 16: ...page16 595 ML CRL S 800 00177 Maintenance A PREVENTIVE MAINTENANCE Maintenance...

Page 27: ...page27 595 ML CRL S 800 00177 Maintenance B HYDRAULIC SYSTEM...

Page 33: ...page33 595 ML CRL S 800 00177 HYDRAULIC PRESSURE ADJUSTMENT CONTINUED 558 01699...

Page 44: ...page44 595 ML CRL S 800 00177 Maintenance C ELECTRICAL SYSTEM MAINTENANCE...

Page 67: ...page67 595 ML CRL S 800 00177 Maintenance D POWER UNIT MAINTENANCE...

Page 77: ...page77 595 ML CRL S 800 00177 Structural E STRUCTURAL MAINTENANCE...

Page 84: ...page84 595 ML CRL S 800 00177 Trouble Shooting Marker Marker Marker...