page 133

page 133

page 133

page 133

page 133

160B&C TM

800-00140

Grapple hanger referenced below may be installed on grapple at factory. All grapple relief valve pressures are preset at

factory and should not need adjusting.

GRAPPLE INSTALLATION

GRAPPLE INSTALLATION

GRAPPLE INSTALLATION

GRAPPLE INSTALLATION

GRAPPLE INSTALLATION

Before installing grapple to loader boom, check loader for the three items listed below:

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Failure to perform the following three checks could result in damage

Failure to perform the following three checks could result in damage

Failure to perform the following three checks could result in damage

Failure to perform the following three checks could result in damage

Failure to perform the following three checks could result in damage

to rotate system of grapple and void warranty.

to rotate system of grapple and void warranty.

to rotate system of grapple and void warranty.

to rotate system of grapple and void warranty.

to rotate system of grapple and void warranty.

1) Oil flow going to grapple should not exceed 10 GPM. If it does, a flow restrictor must be installed in the grapple rotate

supply line either at the valve or in the line between the valve and the rotate motor to limit flow to rotate motor.

2) Open/close pressure must not exceed 3200 PSI for any grapple unless approved by the factory for the application.

3) Return flow of oil from grapple rotate circuit should be as free as possible to prevent back pressure at rotate motor.

Consult factory for further information.

Once the above steps are performed, proceed with the following steps to attach grapple to loader boom:

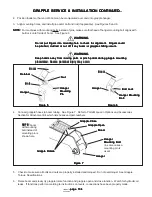

1. Set grapple upright on a solid surface to prevent tipping during installation. Rotators must be positioned as follows:

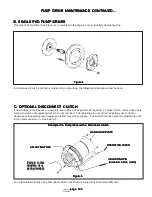

----- for 50B new style and old style CR rotators: Ensure that motor is positioned away from loader, as shown in

Figure 1.

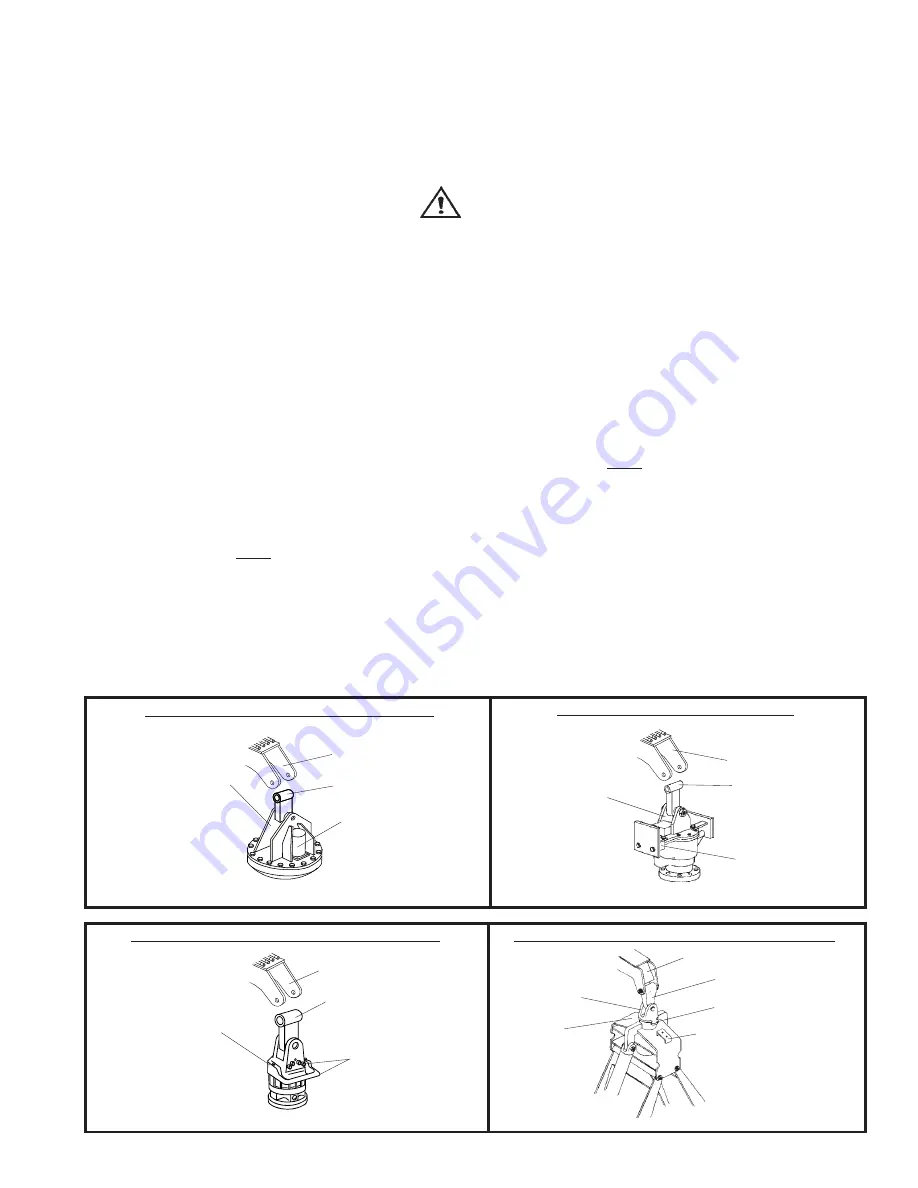

----- for 20K CR rotators: Ensure that crossover relief valve is pointed toward operator's right, as shown in Figure 2.

----- for 22I vane type CR rotators: Fittings and guard should point away from the operator, as shown in Figure 3.

----- for 280 and 360 degree non-CR rotators: Ensure that manifold plate and rotate stop (280 degree rotators only)

are positioned away from loader, as shown in Figure 4.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: The 280 degree grapple uses a vane motor which, along with the rotate stop, help stop rotation at 280 degrees.

The 360 degree grapple must be stopped by loader operator. It does not have any

stops on it. If it is rotated continually, hoses will be wrapped around grapple causing them to break.

Figure 1

Figure 1

Figure 1

Figure 1

Figure 1

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

Rotator

Rotator

Rotator

Rotator

Rotator

Motor

Motor

Motor

Motor

Motor

Hanger

Hanger

Hanger

Hanger

Hanger

Boom

Boom

Boom

Boom

Boom

Barko-Built Continuous Rotation Rotator

Barko-Built Continuous Rotation Rotator

Barko-Built Continuous Rotation Rotator

Barko-Built Continuous Rotation Rotator

Barko-Built Continuous Rotation Rotator

20K Continuous Rotation Rotator

20K Continuous Rotation Rotator

20K Continuous Rotation Rotator

20K Continuous Rotation Rotator

20K Continuous Rotation Rotator

Crossover

Crossover

Crossover

Crossover

Crossover

Relief Valve

Relief Valve

Relief Valve

Relief Valve

Relief Valve

Rotator

Rotator

Rotator

Rotator

Rotator

Hanger

Hanger

Hanger

Hanger

Hanger

Boom

Boom

Boom

Boom

Boom

Boom

Boom

Boom

Boom

Boom

Hanger

Hanger

Hanger

Hanger

Hanger

Rotator

Rotator

Rotator

Rotator

Rotator

280 degree Non-Continuous Rotation Rotator

280 degree Non-Continuous Rotation Rotator

280 degree Non-Continuous Rotation Rotator

280 degree Non-Continuous Rotation Rotator

280 degree Non-Continuous Rotation Rotator

Figure 3

Figure 3

Figure 3

Figure 3

Figure 3

Yoke

Yoke

Yoke

Yoke

Yoke

Rotate Stop

Rotate Stop

Rotate Stop

Rotate Stop

Rotate Stop

Manifold Plate

Manifold Plate

Manifold Plate

Manifold Plate

Manifold Plate

Rotator

Rotator

Rotator

Rotator

Rotator

22

22

22

22

22

I

Vane Type Continuous Rotation Rotator

Vane Type Continuous Rotation Rotator

Vane Type Continuous Rotation Rotator

Vane Type Continuous Rotation Rotator

Vane Type Continuous Rotation Rotator

Boom

Boom

Boom

Boom

Boom

Hanger

Hanger

Hanger

Hanger

Hanger

Figure 4

Figure 4

Figure 4

Figure 4

Figure 4

Fittings

Fittings

Fittings

Fittings

Fittings

and

and

and

and

and

Guard

Guard

Guard

Guard

Guard

GRAPPLE SERVICE & INSTALLATION

GRAPPLE SERVICE & INSTALLATION

GRAPPLE SERVICE & INSTALLATION

GRAPPLE SERVICE & INSTALLATION

GRAPPLE SERVICE & INSTALLATION