page 34

page 34

page 34

page 34

page 34

160B&C TM

800-00140

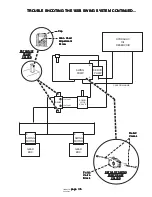

TROUBLE SHOOTING THE SWING SYSTEM

TROUBLE SHOOTING THE SWING SYSTEM

TROUBLE SHOOTING THE SWING SYSTEM

TROUBLE SHOOTING THE SWING SYSTEM

TROUBLE SHOOTING THE SWING SYSTEM

(See illustration on next page)

(See illustration on next page)

(See illustration on next page)

(See illustration on next page)

(See illustration on next page)

1.

1.

1.

1.

1. CHECK PUMP (TA-19/V10) 560-00946

CHECK PUMP (TA-19/V10) 560-00946

CHECK PUMP (TA-19/V10) 560-00946

CHECK PUMP (TA-19/V10) 560-00946

CHECK PUMP (TA-19/V10) 560-00946

a. Disconnect pressure lines at a A and B ports on pump.

b. Install 5000 PSI gauges on A and B ports on pump (where you disconnected hoses).

c. With engine at an idle, slowly engage swing pedal (read PSI in both directions - should read 4000 PSI to 4500

PSI both directions).

d. If PSI is low in one direction, switch relief cartridges (in pump) from side to side.

e. Take PSI readings again. If low reading appears in opposite gauge, replace bad relief.

f.

Check pressure again.

g. If pressures are low on both sides, replace pump.

2.

2.

2.

2.

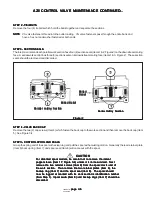

2. CHECK SWING RELIEF BLOCK

CHECK SWING RELIEF BLOCK

CHECK SWING RELIEF BLOCK

CHECK SWING RELIEF BLOCK

CHECK SWING RELIEF BLOCK

a. Install 5000 PSI gauges on test ports.

b. Stall swing by jamming grapple in the ground (swing lock must be off). Read pressures - both directions,

should be 3000 PSI.

c. If PSI varies, adjust accelerating pressure relief to correct variance.

WARNING

WARNING

WARNING

WARNING

WARNING

Do not adjust relief while machine is running. Shut engine down,

Do not adjust relief while machine is running. Shut engine down,

Do not adjust relief while machine is running. Shut engine down,

Do not adjust relief while machine is running. Shut engine down,

Do not adjust relief while machine is running. Shut engine down,

remove relief cap, make adjustment and replace cap.

remove relief cap, make adjustment and replace cap.

remove relief cap, make adjustment and replace cap.

remove relief cap, make adjustment and replace cap.

remove relief cap, make adjustment and replace cap.

d. If adjusting makes no difference, remove both accelerating and braking pressure reliefs, check o-rings, then

switch reliefs from top to bottom.

If swing pressure is 2000 PSI in both directions, remove reliefs, put upper relief in lower cavity again (where it

was originally) and replace accelerating pressure relief.

If 2000 PSI is not seen in both directions, test swing motors as described below.

e. If reliefs check out properly, proceed to swing motor.

3.

3.

3.

3.

3. TEST SWING MOTORS

TEST SWING MOTORS

TEST SWING MOTORS

TEST SWING MOTORS

TEST SWING MOTORS

a. Disconnect pressure lines to one motor and plug hoses (eliminate motor from system).

b. Test system pressure now. This will tell if motor left in system is good.

c. Next, disconnect this motor from system. Re-hook up other motor. Test system PSI again. This will tell you if

second motor is good.

d. If PSI varies greatly in either motor, replace bad motor.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

When replacing any major component in swing system, it is important

When replacing any major component in swing system, it is important

When replacing any major component in swing system, it is important

When replacing any major component in swing system, it is important

When replacing any major component in swing system, it is important

to flush out all remaining components: motors, pump, hoses, etc. This is a

to flush out all remaining components: motors, pump, hoses, etc. This is a

to flush out all remaining components: motors, pump, hoses, etc. This is a

to flush out all remaining components: motors, pump, hoses, etc. This is a

to flush out all remaining components: motors, pump, hoses, etc. This is a

closed loop system and contamination left in the system will affect the life of all

closed loop system and contamination left in the system will affect the life of all

closed loop system and contamination left in the system will affect the life of all

closed loop system and contamination left in the system will affect the life of all

closed loop system and contamination left in the system will affect the life of all

components.

components.

components.

components.

components.