page 36

page 36

page 36

page 36

page 36

160B&C TM

800-00140

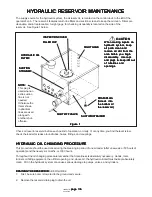

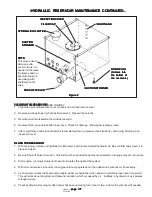

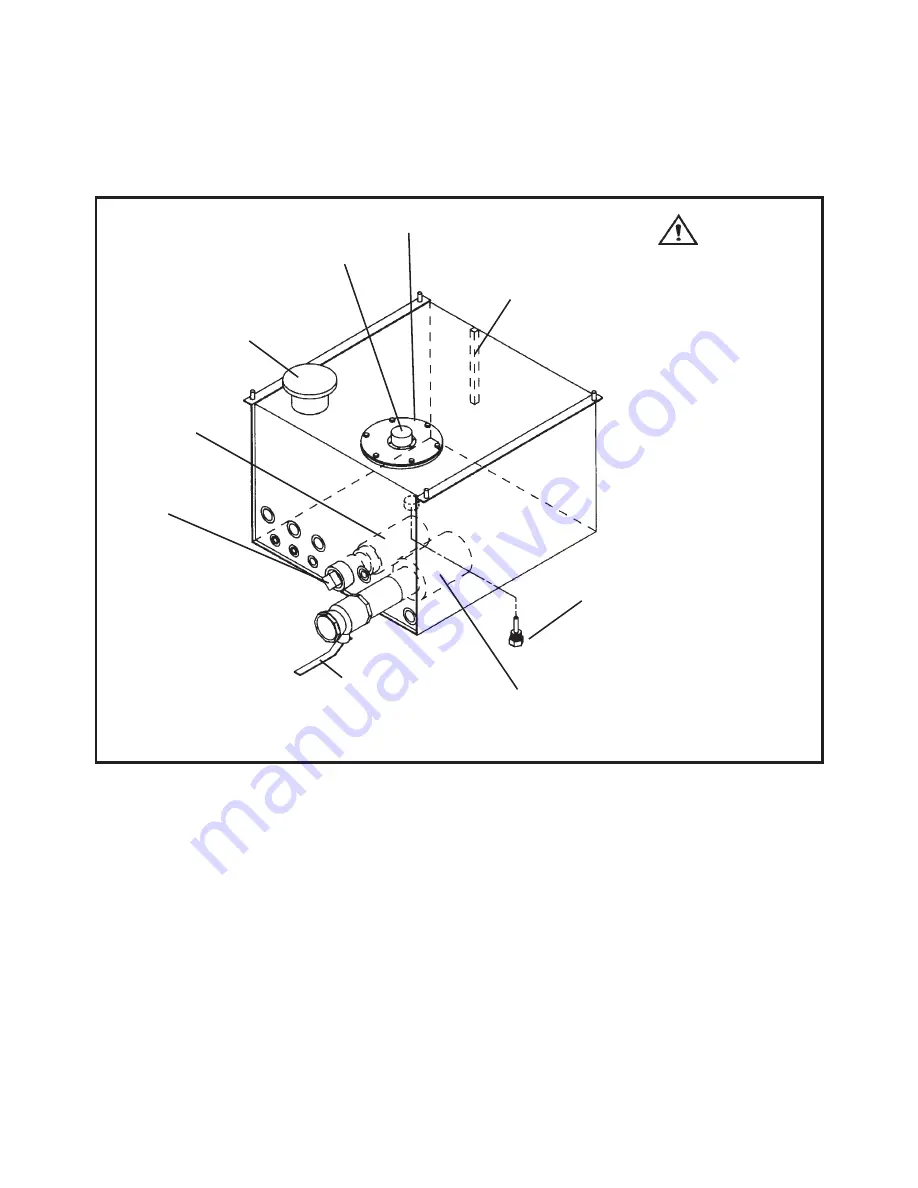

The supply source for the hydraulic system, the oil reservoir, is located on the control deck to the left of the

operator's cab. The reservoir features return line filters and suction screens to keep the oil clean. Filters are

cleanable, and/or replaceable. A sight gage for checking oil quantity is located on the side of the

reservoir. See Figure 1 below.

HYDRAULIC RESERVOIR MAINTENANCE

HYDRAULIC RESERVOIR MAINTENANCE

HYDRAULIC RESERVOIR MAINTENANCE

HYDRAULIC RESERVOIR MAINTENANCE

HYDRAULIC RESERVOIR MAINTENANCE

INSPECTION COVER

INSPECTION COVER

INSPECTION COVER

INSPECTION COVER

INSPECTION COVER

FILLER CAP

FILLER CAP

FILLER CAP

FILLER CAP

FILLER CAP

HYDRAULIC OIL

HYDRAULIC OIL

HYDRAULIC OIL

HYDRAULIC OIL

HYDRAULIC OIL

FILTER

FILTER

FILTER

FILTER

FILTER

SUCTION STRAINER

SUCTION STRAINER

SUCTION STRAINER

SUCTION STRAINER

SUCTION STRAINER

DRAIN PLUG

DRAIN PLUG

DRAIN PLUG

DRAIN PLUG

DRAIN PLUG

(Screws into

(Screws into

(Screws into

(Screws into

(Screws into

the bottom of

the bottom of

the bottom of

the bottom of

the bottom of

the reservoir.)

the reservoir.)

the reservoir.)

the reservoir.)

the reservoir.)

SHUT-OFF VALVE

SHUT-OFF VALVE

SHUT-OFF VALVE

SHUT-OFF VALVE

SHUT-OFF VALVE

SUCTION

SUCTION

SUCTION

SUCTION

SUCTION

STRAINER

STRAINER

STRAINER

STRAINER

STRAINER

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

This plug is

used when an

extra suction

line is not

needed.

Otherwise the

items shown

in phantom

lines are used

along with

another shut-

off valve.

SIGHT GAGE

SIGHT GAGE

SIGHT GAGE

SIGHT GAGE

SIGHT GAGE

When making repairs on

When making repairs on

When making repairs on

When making repairs on

When making repairs on

hydraulic system, keep

hydraulic system, keep

hydraulic system, keep

hydraulic system, keep

hydraulic system, keep

all

all

all

all

all parts clean and

parts clean and

parts clean and

parts clean and

parts clean and

remove

remove

remove

remove

remove all dirt from the

all dirt from the

all dirt from the

all dirt from the

all dirt from the

area

area

area

area

area before you begin

before you begin

before you begin

before you begin

before you begin

dis

dis

dis

dis

disassembly. Use caps

assembly. Use caps

assembly. Use caps

assembly. Use caps

assembly. Use caps

and

and

and

and

and plugs to keep dirt out

plugs to keep dirt out

plugs to keep dirt out

plugs to keep dirt out

plugs to keep dirt out

of

of

of

of

of tubelines and

tubelines and

tubelines and

tubelines and

tubelines and

openings.

openings.

openings.

openings.

openings.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Figure 1

Figure 1

Figure 1

Figure 1

Figure 1

Check oil level in reservoir before each period of operation, or daily. If, at any time, you find the level is low,

check the loader for leaks around tubes, hoses, fittings, and couplings.

HYDRAULIC OIL CHANGING PROCEDURE

HYDRAULIC OIL CHANGING PROCEDURE

HYDRAULIC OIL CHANGING PROCEDURE

HYDRAULIC OIL CHANGING PROCEDURE

HYDRAULIC OIL CHANGING PROCEDURE

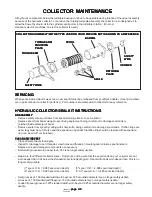

This procedure should be used once during the breaking in period of a new loader (after one week, or 50 hours of

operation) and then every six months, or 1000 hours.

Throughout the oil changing procedure remember that cleanliness is absolutely necessary. Hands, tools,

funnels, oil filling equipment, the oil filler opening, and, above all, the hydraulic oil itself must be kept absolutely

clean. Dirt in the hydraulic system can cause serious damage to pumps, valves, and cylinders.

DRAINING THE RESERVOIR

DRAINING THE RESERVOIR

DRAINING THE RESERVOIR

DRAINING THE RESERVOIR

DRAINING THE RESERVOIR SEE FIGURE 2.

1. First, be sure boom is lowered to the ground and secure.

2. Remove the reservoir drain plug to drain the oil.