page 46

page 46

page 46

page 46

page 46

160B&C TM

800-00140

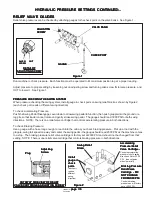

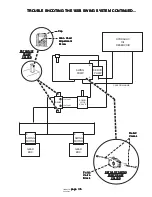

A20 CONTROL VALVE MAINTENANCE CONTINUED...

A20 CONTROL VALVE MAINTENANCE CONTINUED...

A20 CONTROL VALVE MAINTENANCE CONTINUED...

A20 CONTROL VALVE MAINTENANCE CONTINUED...

A20 CONTROL VALVE MAINTENANCE CONTINUED...

STEP 2 - TIE BOLTS

STEP 2 - TIE BOLTS

STEP 2 - TIE BOLTS

STEP 2 - TIE BOLTS

STEP 2 - TIE BOLTS

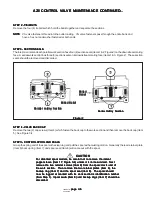

Remove the four (4) tie bolts which hold the bank together and separate the sections.

NOTE

NOTE

NOTE

NOTE

NOTE: VA valve fasteners thread into the outlet casting. VG valve fasteners pass through the entire bank and

have a hex nut and washer fastened at both ends.

STEP 3 - SECTION SEALS

STEP 3 - SECTION SEALS

STEP 3 - SECTION SEALS

STEP 3 - SECTION SEALS

STEP 3 - SECTION SEALS

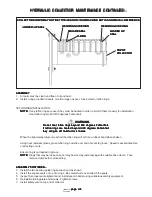

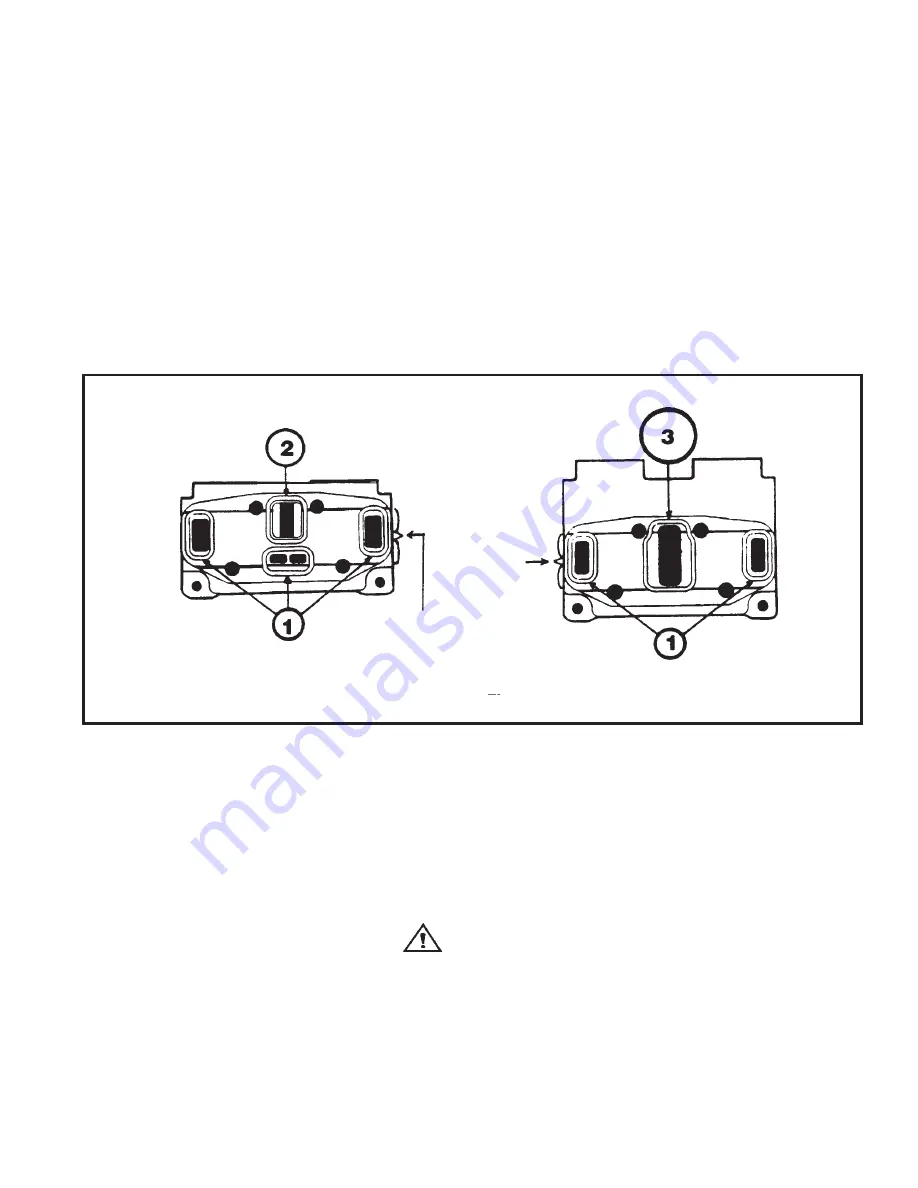

The inlet, mid-inlet and each parallel work section have four (4) section seals (Items 1 & 2, Figure 2) on the downstream mating

face. A series work section has three (3) section seals on its downstream mating face (Items 1 & 3, Figure 2). These section

seals should be removed and discarded.

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

STEP 4 - VALVE BACK CAP

STEP 4 - VALVE BACK CAP

STEP 4 - VALVE BACK CAP

STEP 4 - VALVE BACK CAP

STEP 4 - VALVE BACK CAP

Remove the two (2) cap screws (Item 4) which fasten the back cap to the work section and then remove the back cap (Item

5). See Figure 3-4.

STEP 5 - CONTROL SPOOL AND SEALS

STEP 5 - CONTROL SPOOL AND SEALS

STEP 5 - CONTROL SPOOL AND SEALS

STEP 5 - CONTROL SPOOL AND SEALS

STEP 5 - CONTROL SPOOL AND SEALS

Grasp the spring end of the spool with a clean rag and pull the spool with a twisting motion. Generally the rear retainer plate

(Item 6) backup ring (Item 7) and spool seal (Item 8) will come out with the spool.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

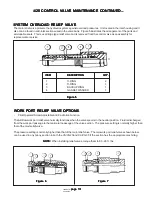

For detented spool models, be careful not to remove the detent

For detented spool models, be careful not to remove the detent

For detented spool models, be careful not to remove the detent

For detented spool models, be careful not to remove the detent

For detented spool models, be careful not to remove the detent

poppet sleeve (Item 17, Figure 3-4) unless it is to be serviced. Next

poppet sleeve (Item 17, Figure 3-4) unless it is to be serviced. Next

poppet sleeve (Item 17, Figure 3-4) unless it is to be serviced. Next

poppet sleeve (Item 17, Figure 3-4) unless it is to be serviced. Next

poppet sleeve (Item 17, Figure 3-4) unless it is to be serviced. Next

remove the two retainer screws (Item 9) from the spool clevis end of

remove the two retainer screws (Item 9) from the spool clevis end of

remove the two retainer screws (Item 9) from the spool clevis end of

remove the two retainer screws (Item 9) from the spool clevis end of

remove the two retainer screws (Item 9) from the spool clevis end of

the work section. Then remove the two retainer plates (Item 6), the

the work section. Then remove the two retainer plates (Item 6), the

the work section. Then remove the two retainer plates (Item 6), the

the work section. Then remove the two retainer plates (Item 6), the

the work section. Then remove the two retainer plates (Item 6), the

backup ring (Item 7) and the spool seal (Item 8). The spool should

backup ring (Item 7) and the spool seal (Item 8). The spool should

backup ring (Item 7) and the spool seal (Item 8). The spool should

backup ring (Item 7) and the spool seal (Item 8). The spool should

backup ring (Item 7) and the spool seal (Item 8). The spool should

now be tagged or marked with its work section’s identification number

now be tagged or marked with its work section’s identification number

now be tagged or marked with its work section’s identification number

now be tagged or marked with its work section’s identification number

now be tagged or marked with its work section’s identification number

(from Step 1). Spool seals (Item 8) and backup rings (Item 7) should be

(from Step 1). Spool seals (Item 8) and backup rings (Item 7) should be

(from Step 1). Spool seals (Item 8) and backup rings (Item 7) should be

(from Step 1). Spool seals (Item 8) and backup rings (Item 7) should be

(from Step 1). Spool seals (Item 8) and backup rings (Item 7) should be

discarded.

discarded.

discarded.

discarded.

discarded.

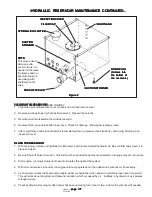

Parallel Lo-Boy Section

Parallel Lo-Boy Section

Parallel Lo-Boy Section

Parallel Lo-Boy Section

Parallel Lo-Boy Section

Milled Relief

Milled Relief

Milled Relief

Milled Relief

Milled Relief

Milled

Milled

Milled

Milled

Milled

Relief

Relief

Relief

Relief

Relief

Series Hi-Boy Section

Series Hi-Boy Section

Series Hi-Boy Section

Series Hi-Boy Section

Series Hi-Boy Section