page 67

page 67

page 67

page 67

page 67

160B&C TM

800-00140

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

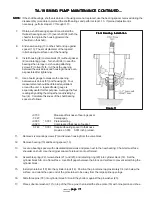

c. Slide yoke (37) from side to side to loosen yoke bearing races

(35) and (36) within the housing. The races are a normal slip fit

but may be tight. Use an open end wrench between the yoke

and the pintle bearing to help slide out the races. Apply

pressure to bearing (35) or (36) at the approximate center and

allow the bearing rollers to gently press the race out of the

housing.

d. Remove yoke (37) from housing (8).

3. Lift front shaft bearing (38) from the housing. DO NOT

DO NOT

DO NOT

DO NOT

DO NOT remove the

bearing race unless bearing was found defective. Use special tool

shown in Figure 5.

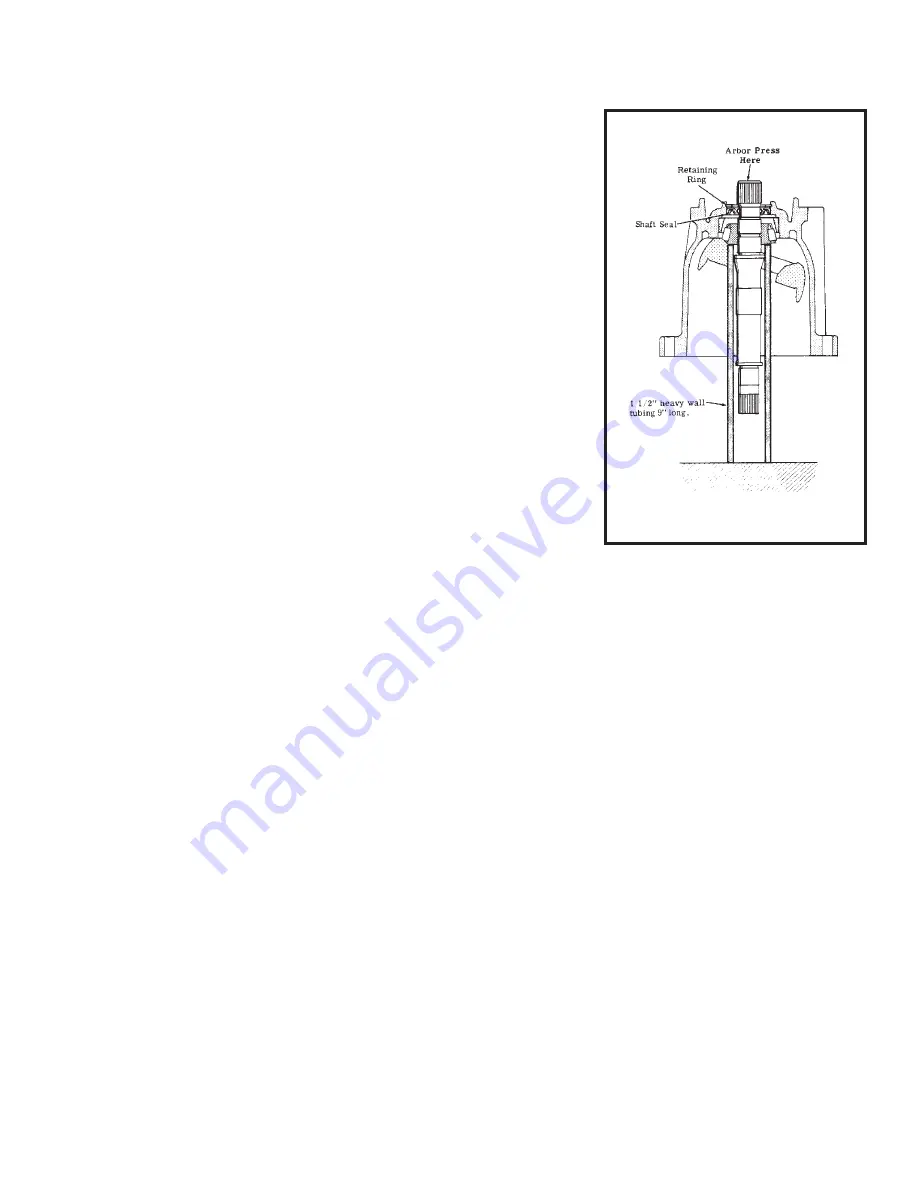

4. Remove retaining ring (39) and press shaft seal (40) out of the housing.

Use a short piece of 1-1/2 inch heavy wall tubing as a tool or if the yoke

was not removed, use a brass rod and work from the inside of the

housing to remove seal (40).

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: All parts must be thoroughly cleaned and kept clean during

inspection and assembly. Clean all removed parts, using a

commercial solvent that is compatible with the system fluid.

Compressed air may be used in cleaning, but it must be filtered to

remove water and contamination. Clean compressed air is

particularly useful in cleaning valve block passages.

Front Bearing Removal

Front Bearing Removal

Front Bearing Removal

Front Bearing Removal

Front Bearing Removal

Figure 9

Figure 9

Figure 9

Figure 9

Figure 9

F. INSPECTION REPAIR AND REPLACEMENT

F. INSPECTION REPAIR AND REPLACEMENT

F. INSPECTION REPAIR AND REPLACEMENT

F. INSPECTION REPAIR AND REPLACEMENT

F. INSPECTION REPAIR AND REPLACEMENT

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Replace all parts that do not meet the following specifications.

1.

Check bearing spacer (13) for burrs. Remove small burrs with an India stone.

2.

Inspect cylinder block face (14) for wear, scratches, and/or erosion between cylinders. Check the spring,

washer, and retaining ring located within the cylinder block.

3.

Check each cylinder block bore for excessive wear. Use the piston and shoe subassemblies (15) for this

purpose. The piston should be a very close fit and slide easily in and out of the bore. No bind can be tolerated.

If binding is evident, clean the cylinder block and piston, lubricate with clean hydraulic fluid and try again. Even

minor contamination of the fluid could cause the piston to freeze up in the cylinder bore.

4.

Inspect each piston and shoe subassembly (15) for a maximum end play of 0.005 inch between the piston and

shoe.

5.

The face thickness dimension of each shoe must be within 0.001 inch of each other.

6.

Inspect shoe plate (16) for excessive wear and cracking in the area of spherical washer (17). If heavy wear or

cracks are found, replace the shoe plate and spherical washer at the same time.

7.

Check spherical washer (17) for burrs, wear, and possible scratches due to pin (18) breakage. Replace if wear

is excessive.

8.

Inspect pins (18) for equal length, excessive wear, and possible bending. Replace all pins simultaneously if one

is defective.

9.

The pin retainer (19) may develop burrs. Remove all burrs with an India Stone.