page 74

page 74

page 74

page 74

page 74

160B&C TM

800-00140

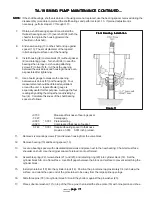

C. FLOW CONTROL AND RELIEF VALVE

C. FLOW CONTROL AND RELIEF VALVE

C. FLOW CONTROL AND RELIEF VALVE

C. FLOW CONTROL AND RELIEF VALVE

C. FLOW CONTROL AND RELIEF VALVE

Pumps are available with an integral Flow Control and Relief Valve in the pump cover. This limits the fluid flow in the system

to a maximum prescribed rate and prevents excessive pressure build-up. Fluid not required in the system is recirculated to

tank.

D. PRIORITY VALVE

D. PRIORITY VALVE

D. PRIORITY VALVE

D. PRIORITY VALVE

D. PRIORITY VALVE

Pumps are also available with a priority valve located in the pump cover. The priority valve maintains nearly a constant flow

to a primary circuit and diverts the remaining flow to a secondary circuit. Flow going to the secondary circuit is determined

by pump delivery. The primary circuit is protected by an integral relief valve but an external relief valve must be provided for

the secondary circuit.

E. APPLICATION

E. APPLICATION

E. APPLICATION

E. APPLICATION

E. APPLICATION

Pump ratings in GPM as shown in the model coding are at 1200 RPM and 100 PSI. For ratings at other speeds, methods

of installation, and other application information, engineering personnel should be consulted.

SECTION III - PRINCIPLES OF OPERATION

SECTION III - PRINCIPLES OF OPERATION

SECTION III - PRINCIPLES OF OPERATION

SECTION III - PRINCIPLES OF OPERATION

SECTION III - PRINCIPLES OF OPERATION

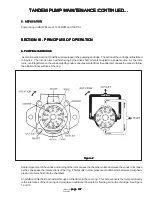

A. PUMPING CARTRIDGE

A. PUMPING CARTRIDGE

A. PUMPING CARTRIDGE

A. PUMPING CARTRIDGE

A. PUMPING CARTRIDGE

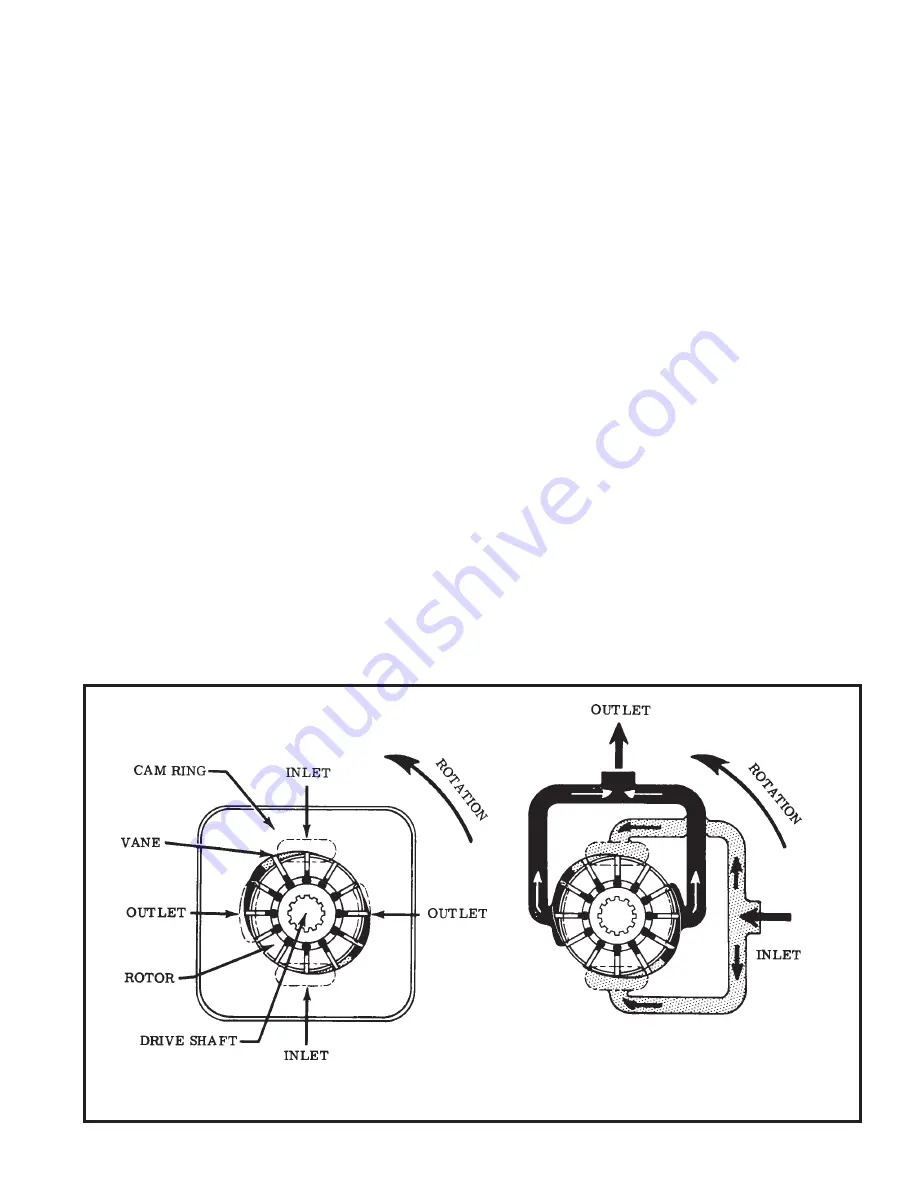

Fluid flow is developed by the pumping cartridge. The action of the cartridge is illustrated in Figure 2. The rotor is driven within

the cam ring by the drive shaft, which is coupled to a power source. As the rotor turns, centrifugal force causes the vanes

to follow the elliptical inner surface of the cam ring.

Radial movement of the vanes and turning of the rotor cause the chamber volume between the vanes to increase as the vanes

pass the inlet sections of the cam ring. This results in a low pressure condition which allows atmospheric pressure to force

fluid into the chambers. (Fluid outside the inlet is at atmospheric pressure or higher).

This fluid is trapped between the vanes and carried past the large diameter or dwell section of the cam ring. As the outlet

section is approached, the cam ring diameter decreases and the fluid is forced out into the system. System pressure is fed

under the vanes, assuring their sealing contact against the cam ring during normal operation.

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...