page 96

page 96

page 96

page 96

page 96

160B&C TM

800-00140

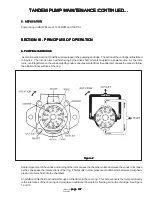

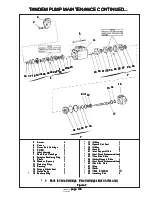

c. Place the cartridge on a flat surface (outlet support plate down) and remove the two socket head

screws (20).

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DO NOT slide flex plates across the ring and rotor.

DO NOT slide flex plates across the ring and rotor.

DO NOT slide flex plates across the ring and rotor.

DO NOT slide flex plates across the ring and rotor.

DO NOT slide flex plates across the ring and rotor.

Burrs on the ring or rotor can cause deep scratches

Burrs on the ring or rotor can cause deep scratches

Burrs on the ring or rotor can cause deep scratches

Burrs on the ring or rotor can cause deep scratches

Burrs on the ring or rotor can cause deep scratches

in the soft bronze surface.

in the soft bronze surface.

in the soft bronze surface.

in the soft bronze surface.

in the soft bronze surface.

d. Slide inlet support plate (21) and seal pack subassemblies (22) off the cartridge. DO NOT allow

the flex side plate (23) to slide with the support plate.

e. Move flex side plate (23) off center just enough to lift up and away without sliding.

f.

Place a small clean piece of wood over the exposed ring and rotor. Reverse the position of the

cartridge.

g. Slide outlet support plate (24) and seal pack subassemblies (25) off flex side plate (26). DO NOT

permit flex side plate (26) to move across the ring and rotor.

h. Move flex side plate (26) off center just enough to lift up and away without sliding.

i.

Lift ring (27) away from the rotor (28) and vanes (29). Locate the arrow stamped into the rotor

periphery. Remove the vanes and inserts in order, starting at the arrow. Keep them in order for

inspection.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Do not remove cartridge locating pins (30) from the inlet support plate unless they are damaged. The

pins are of a drive-loc type and can be difficult to remove.

C. INSPECTION AND REPAIR

C. INSPECTION AND REPAIR

C. INSPECTION AND REPAIR

C. INSPECTION AND REPAIR

C. INSPECTION AND REPAIR

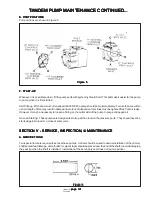

Cleaning: All parts must be thoroughly cleaned and kept clean during inspection and assembly. The close tolerance

of the parts makes this requirement very important. Clean all removed parts, using a commercial solvent that is

compatible with the system fluid. Compressed air may be used in cleaning, but it must be filtered to remove water

and contamination.

Discard the shaft seal(s), o-rings, back-up ring, and seal pack subassemblies. Use a new seal kit for reassembly.

Wash the metal parts, blow them dry with air, and place on a clean surface for inspection.

1. Check the cartridge wear surfaces for pickup, scoring, and excessive wear. Slight heat discoloration of the

flex side plate bronze surface is normal. Score marks deeper than 0.001 inch and scratches deeper than 0.002

inch indicate a new part is needed. Slight scoring and/or scratches can be removed

with an oiled Arkansas stone.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DO NOT use a dry stone on the bronze surface or

DO NOT use a dry stone on the bronze surface or

DO NOT use a dry stone on the bronze surface or

DO NOT use a dry stone on the bronze surface or

DO NOT use a dry stone on the bronze surface or

scratches will result.

scratches will result.

scratches will result.

scratches will result.

scratches will result.

2. Inspect both sides of each vane (29) and insert in order. If pickup, heavy wear, or scoring is found inspect

the appropriate rotor (28) slot. Replace scored parts.

3. Inspect ring (27) for vane chatter marks, wear and/or scratches. Replace if scoring is evident.

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...