page 42

page 42

page 42

page 42

page 42

275B SER

800-00152

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

-

Assemble the spring (Item 15), spring guides (Item 16) and stripper bolt (Item 14) onto the spool (Reverse of Step

7). Lightly coat the spring assembly with high temperature grease to prevent rusting.

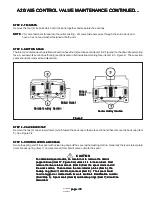

SPOOL ASSEMBLY - DETENTED

SPOOL ASSEMBLY - DETENTED

SPOOL ASSEMBLY - DETENTED

SPOOL ASSEMBLY - DETENTED

SPOOL ASSEMBLY - DETENTED

-

Clamp the control spool in a soft jawed vise. Apply a small amount of Loctite 262 or equivalent anaerobic

adhesive to the detent poppet retainer (Item 20) and thread it into the control spool.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Follow the adhesive manufacturer’s instruction for

Follow the adhesive manufacturer’s instruction for

Follow the adhesive manufacturer’s instruction for

Follow the adhesive manufacturer’s instruction for

Follow the adhesive manufacturer’s instruction for

proper cleaning and curing. Failure to clean and

proper cleaning and curing. Failure to clean and

proper cleaning and curing. Failure to clean and

proper cleaning and curing. Failure to clean and

proper cleaning and curing. Failure to clean and

prepare parts properly may result in assembly failure.

prepare parts properly may result in assembly failure.

prepare parts properly may result in assembly failure.

prepare parts properly may result in assembly failure.

prepare parts properly may result in assembly failure.

-

Then lightly coat the detent balls (Item 18), detent spring (Item 19) and detent sleeve (Item 17) with high

temperature grease.

-

Next place the detent balls and spring into the detent poppet retainer as shown in Step 8 and partially compress

them with a small clamp.

-

Now slide the detent sleeve into position, pushing the clamp out of the way at the same time.

VALVE SECTION ASSEMBLY

VALVE SECTION ASSEMBLY

VALVE SECTION ASSEMBLY

VALVE SECTION ASSEMBLY

VALVE SECTION ASSEMBLY

-

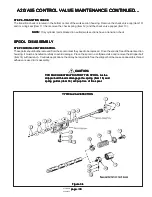

Apply a light coating of clean hydraulic oil to the valve spool.

-

Place the retaining plates (Item 6), new backup rings (Item 7) and new spool seals (Item 8) in position as shown in

Figure 3-4.

-

Carefully insert the spool into the housing. Make sure that the spool and housing are in the proper orien

tation (see Step 1).

-

Place Loctite 262 or its equivalent on the back cap screws (Item 4) and front retainer screws (Item 9) threading

them into the valve housing.

When installing the transition check refer to Step 6. Torque cap screws to 80 - 90 ft. lbs.

VALVE BANK ASSEMBLY

VALVE BANK ASSEMBLY

VALVE BANK ASSEMBLY

VALVE BANK ASSEMBLY

VALVE BANK ASSEMBLY

-

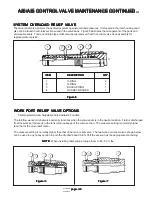

Return all relief valves to their proper positions (see Step 1).

-

Coat the section seals (Items 1 & 2 or Items 1 & 3) with grease and place them in their grooves (Figure 2).

-

Place the valve sections on the tie bolts in their proper sequence (see Step 1).

-

Torque the tie bolts in a cross pattern to:

VA20-29 foot pounds

VG20-42 foot pounds

VA35-34 foot pounds

VG35-75 foot pounds