page 65

page 65

page 65

page 65

page 65

275B SER

800-00152

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

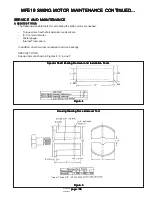

10. Locate a bearing spacer with calculated dimensions and place with shaft bearing (5). Use the original spacer if

preload is not performed. Set aside for final assembly.

11. Assemble spring (17), two washers (16) and (18) and retaining ring (15) into the cylinder block (9). See Figure 9

for instructions. Set the cylinder block S/A on a flat surface. Use Kraft paper between the block and surface to

prevent scratching the cylinder block face.

12. Install pin retainer (14) into cylinder block S/A until they bottom against pin washer (18).

13. Slide three pins (13) into cylinder block S/A until they bottom against pin washer (18).

14. Place spherical washer (12) on top of the three pins: Then install the shoe plate (11) with nine piston and shoe

subassemblies (10) over the spherical washer and into the cylinder block S/A. Wobble the shoe plate to make

sure that each piston is free within it's bore in the cylinder block. (Flood all parts with clean hydraulic fluid).

15. Install swash plate (20) over shaft (21) into housing (3). Set housing (3) on it's side and hold the shaft end so

drive shaft 921) is horizontal. Slide the rotating group into the housing. Rotate drive shaft (21) if necessary, to

match the shaft splines to cylinder block 9) and spherical washer (12).

16. Install bearing spacer (8) with chamfer toward the shoulder of drive shaft (21).

17. Install tapered roller bearing (5) over the shaft and against the spacer. The small diameter of the tapered roller

bearing must face toward valve block (2).

18. Install two housing pins (19) and place a new gasket (4) over them. Cover the unit and set aside for final

assembly.

F.

F.

F.

F.

F. FINAL ASSEMBLY OF PISTON MOTOR

FINAL ASSEMBLY OF PISTON MOTOR

FINAL ASSEMBLY OF PISTON MOTOR

FINAL ASSEMBLY OF PISTON MOTOR

FINAL ASSEMBLY OF PISTON MOTOR

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Flood all parts with system fluid to provide initial lubrication at assembly.

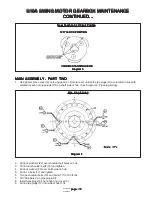

1. Install shaft seal (25) into valve plate (2) with garter spring facing shaft bearing. MFE19X models only. Be

careful not to damage seal during installation.

2. Assemble wafer plate locating pin (7) into valve block (2). Refer to Figure 8.

3. Assemble wafer plate (6) over the bearing race and locating pin (7) with wear surface away from valve block (2).

See Figure 8. Make sure wafer plate is flat against valve block (2). Check height of pin to be sure that it does

not hold the wafer plate away from the valve block.

4. Assemble valve block to housing with four attaching screw (1). Cross torque the screw to 42-45 Lb. Ft., Be

careful not to cut rear shaft seal (25) on through shaft models. (Tape shaft spline with plastic tape).

5. Tape the spline end of drive shaft (21) with plastic tape to prevent cutting new shaft seal (24). Start taping the

shaft close to the housing and work toward the end of the shaft. Install a new shaft seal (24) (garter spring

inward) in position over the shaft and press evenly into the housing. Use shaft seal driver shown in Figure 7.

The seal must be positioned just below (approx. 0.020 inch), the retaining ring groove. Install retaining ring (23)

into the housing. Use internal Truarc pliers to install retaining ring. (NOTE: Shaft seal will contact the tapered

roller bearing and be damaged if pressed too deep into the housing bore.)

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Refer to general procedures concerning oil recommendations, filling of the motor housings, etc., before

placing the inline piston motor into service.