page 78

page 78

page 78

page 78

page 78

275B SER

800-00152

ELECTRICAL MOTOR COUPLING MAINTENANCE

ELECTRICAL MOTOR COUPLING MAINTENANCE

ELECTRICAL MOTOR COUPLING MAINTENANCE

ELECTRICAL MOTOR COUPLING MAINTENANCE

ELECTRICAL MOTOR COUPLING MAINTENANCE

CONTINUED...

CONTINUED...

CONTINUED...

CONTINUED...

CONTINUED...

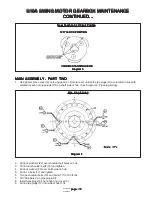

INSTALLATION OF TAPERED GRID

INSTALLATION OF TAPERED GRID

INSTALLATION OF TAPERED GRID

INSTALLATION OF TAPERED GRID

INSTALLATION OF TAPERED GRID

COUPLINGS

COUPLINGS

COUPLINGS

COUPLINGS

COUPLINGS

1. MOUNT SEALS AND HUBS

1. MOUNT SEALS AND HUBS

1. MOUNT SEALS AND HUBS

1. MOUNT SEALS AND HUBS

1. MOUNT SEALS AND HUBS

Lock out starting switch of prime mover. Clean all metal

parts using a non-flammable solvent. Lightly coat seals

with grease and place on shafts BEFORE mounting hubs

(See Figure 2). Mount hubs on their respective shafts so

the hub face is flush with the end of its shaft. Tighten set

screws when furnished. Heat interference fit hubs as

instructed.

2. GAP & ANGULAR ALIGNMENT

2. GAP & ANGULAR ALIGNMENT

2. GAP & ANGULAR ALIGNMENT

2. GAP & ANGULAR ALIGNMENT

2. GAP & ANGULAR ALIGNMENT

Use a spacer bar equal in thickness to the normal gap

specified in Table 1. Insert bar, as shown in Figure 3, to

same depth at 90 degree intervals and measure clearance

between bar and hub face with feelers. The difference in

minimum and maximum measurements must not exceed

the ANGULAR limit specified in Table 1.

3. OFFSET ALIGNMENT

3. OFFSET ALIGNMENT

3. OFFSET ALIGNMENT

3. OFFSET ALIGNMENT

3. OFFSET ALIGNMENT

Align so that a straight edge rests squarely (or within the

limits specified in Table 1) on both hubs a shown in

Figure 4 and also at 90 degree intervals. Check with

feelers. The clearance must not exceed the OFFSET

limit specified in Table 1. Tighten all foundation bolts and

repeat steps 2 and 3. Realign coupling if necessary.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Use a dial indicator for more accurate alignment.

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

Figure 3

Figure 3

Figure 3

Figure 3

Figure 3

Table 1

Table 1

Table 1

Table 1

Table 1

INSTALLATION DATA * (Dimensions-

INSTALLATION DATA * (Dimensions-

INSTALLATION DATA * (Dimensions-

INSTALLATION DATA * (Dimensions-

INSTALLATION DATA * (Dimensions-

Inches)

Inches)

Inches)

Inches)

Inches)

Align couplings within "Operating

Align couplings within "Operating

Align couplings within "Operating

Align couplings within "Operating

Align couplings within "Operating

Alignment Limits" specified above.

Alignment Limits" specified above.

Alignment Limits" specified above.

Alignment Limits" specified above.

Alignment Limits" specified above.

Exceeding these limits reduces coupling

Exceeding these limits reduces coupling

Exceeding these limits reduces coupling

Exceeding these limits reduces coupling

Exceeding these limits reduces coupling

life.

life.

life.

life.

life.

Figure 4

Figure 4

Figure 4

Figure 4

Figure 4