page 39

page 39

page 39

page 39

page 39

475 A CRL

800-00167

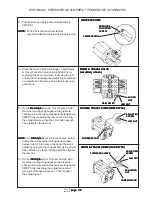

5. Replace element on the diverter/bypass valve assembly and install in the filter housing. Make sure that

the diverter o-ring seats properly into the head.

6. Check to make sure the notch on the diverter/bypass valve assembly lines up with the notch in the head.

7. Inspect the cover o-ring and replace it if necessary.

8. Replace the cover and tighten the hex head cap screws until they are snug. Do not over tighten these screws.

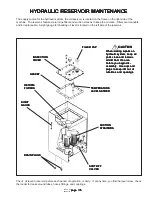

B. THE " SERVO" FILTER

B. THE " SERVO" FILTER

B. THE " SERVO" FILTER

B. THE " SERVO" FILTER

B. THE " SERVO" FILTER

The servo filter has an indicator to show when filter needs servicing. Check indicator daily to ensure proper service

intervals.

CHANGING FILTER ELEMENT

CHANGING FILTER ELEMENT

CHANGING FILTER ELEMENT

CHANGING FILTER ELEMENT

CHANGING FILTER ELEMENT

1. Unscrew filter bowl from filter head.

2. Replace old element with new one inside filter bowl. Screw filter bowl with element inside to filter head.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

These filter elements are not re-usable.

These filter elements are not re-usable.

These filter elements are not re-usable.

These filter elements are not re-usable.

These filter elements are not re-usable.

FILTER ELEMENT

FILTER ELEMENT

FILTER ELEMENT

FILTER ELEMENT

FILTER ELEMENT

FILTER BOWL

FILTER BOWL

FILTER BOWL

FILTER BOWL

FILTER BOWL

FILTER ELEMENT REPLACEMENT INTERVALS

FILTER ELEMENT REPLACEMENT INTERVALS

FILTER ELEMENT REPLACEMENT INTERVALS

FILTER ELEMENT REPLACEMENT INTERVALS

FILTER ELEMENT REPLACEMENT INTERVALS

On new machine filter elements should be replaced after 50 hours of operation and then every 400 hours of

operation after that.

INDICATOR

INDICATOR

INDICATOR

INDICATOR

INDICATOR

FILTER HEAD

FILTER HEAD

FILTER HEAD

FILTER HEAD

FILTER HEAD

HYDRAULIC OIL FILTER MAINTENANCE CONTINUED...