page 68

page 68

page 68

page 68

page 68

475 A CRL

800-00167

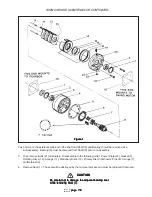

SERVO PUMP MAINTENANCE CONTINUED...

10.On models equipped with keyed drive shaft, install snap ring on drive shaft and install drive key.

11.Check that drive shaft turns with adjustable wrench without evidence of mechanical bind.

BREAK-IN PROCEDURE

BREAK-IN PROCEDURE

BREAK-IN PROCEDURE

BREAK-IN PROCEDURE

BREAK-IN PROCEDURE

TEST STAND METHOD:

TEST STAND METHOD:

TEST STAND METHOD:

TEST STAND METHOD:

TEST STAND METHOD:

1. Run pump for 1 minute at minimum pressure.

2. Raise discharge pressure to 500 PSI (34.5 bar) for 5 seconds, then lower to minimum for 5 seconds. Continue cycle

for 1 minute.

3. Repeat step but increase pressure in 500 PSI (34.5 bar) increments until maximum operating pressure is obtained.

Check flow.

ALTERNATE ON-EQUIPMENT METHOD:

ALTERNATE ON-EQUIPMENT METHOD:

ALTERNATE ON-EQUIPMENT METHOD:

ALTERNATE ON-EQUIPMENT METHOD:

ALTERNATE ON-EQUIPMENT METHOD:

1. Mount pump on equipment and operate for 2 minutes at minimum pressure and one-quarter engine speed.

2. Increase discharge pressure to relief setting with control valve. Hold for 5 seconds and release. Continue cycle for 2

minutes.

3. Repeat step 2 for 3 minutes at one-half engine speed.

4. Repeat step 2 for 3 minutes at full engine speed.

5. With engine at idle speed, check pump and hydraulic system for leaks. No shaft leakage sufficient to form a drop is

permissible. No external leakage is permissible.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

If a new body is installed, break-in of pump will result in wipe chips

If a new body is installed, break-in of pump will result in wipe chips

If a new body is installed, break-in of pump will result in wipe chips

If a new body is installed, break-in of pump will result in wipe chips

If a new body is installed, break-in of pump will result in wipe chips

(which is normal) to be expelled from pump outlet. These small aluminum

(which is normal) to be expelled from pump outlet. These small aluminum

(which is normal) to be expelled from pump outlet. These small aluminum

(which is normal) to be expelled from pump outlet. These small aluminum

(which is normal) to be expelled from pump outlet. These small aluminum

chips can go thru hydraulic system. A high pressure filter with a suitable

chips can go thru hydraulic system. A high pressure filter with a suitable

chips can go thru hydraulic system. A high pressure filter with a suitable

chips can go thru hydraulic system. A high pressure filter with a suitable

chips can go thru hydraulic system. A high pressure filter with a suitable

flow characteristic to match pump output flow should be installed at outlet

flow characteristic to match pump output flow should be installed at outlet

flow characteristic to match pump output flow should be installed at outlet

flow characteristic to match pump output flow should be installed at outlet

flow characteristic to match pump output flow should be installed at outlet

of pump. This precaution will assure these chips do not result in other

of pump. This precaution will assure these chips do not result in other

of pump. This precaution will assure these chips do not result in other

of pump. This precaution will assure these chips do not result in other

of pump. This precaution will assure these chips do not result in other

component failure.

component failure.

component failure.

component failure.

component failure.