page 70

page 70

page 70

page 70

page 70

475 A CRL

800-00167

INTRODUCTION

INTRODUCTION

INTRODUCTION

INTRODUCTION

INTRODUCTION

This manual is a step-by-step guide to assembly and disassembly of torque-hub units. It is designed for the customer

or shop mechanic who is repairing a particular model of torque-hub final drive.

Users of this manual should note that each part mentioned is followed by an identification number enclosed in

parentheses. These part numbers may be referred to in the Parts List section of this manual and on the cross-

sectional view of this unit.

Any specialized tools normally used to assemble this unit are noted in the assembly procedures. However, it is not

mandatory that these tools be used in this unit’s assembly. Bearing cups and cones can be pressed using a punch

and hammer along their top edges. Seals can be pressed by laying a board flat on top of the seal and them hammering

the board down until it meets the hub. Studs can be hammered into stud holes. Should you use these methods,

be very careful not to damage parts when using a punch and/or hammer.

Users should familiarize themselves with the procedures for roll and leak testing and bolt tightening and torquing

found on the following two pages before getting started.

SAFETY

SAFETY

SAFETY

SAFETY

SAFETY

Standard safety practices should be followed during the disassembly and assembly procedures described. Safety

glasses and safety shoes should be worn. Heavy, heat resistant gloves should be used when heated components

are handled. Be especially alert when you see the word CAUTION. This indicates that a particular operation could

cause personal injury if not performed properly or if certain safety procedures are not followed.

ROLL AND LEAK TESTING

ROLL AND LEAK TESTING

ROLL AND LEAK TESTING

ROLL AND LEAK TESTING

ROLL AND LEAK TESTING

Torque-hub units should always be roll and leak tested before disassembly and after assembly to make sure that

the unit’s gears and sealants are working properly. The following information briefly outlines what to look for when

performing these tests.

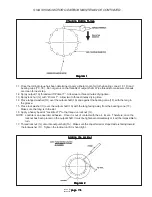

THE ROLL TEST

THE ROLL TEST

THE ROLL TEST

THE ROLL TEST

THE ROLL TEST

The purpose of a roll test is to determine if the unit’s gears are rotating freely and properly. You should be able to

rotate the gears in your unit by applying a constant force to the roll checker. If you feel more drag in the gears only

at certain points, then the gears are not rolling freely and should be examined for proper installation or defects. Some

gear packages roll with more difficulty than others. Do not be concerned if the gears in your unit seem to roll hard

as long as they roll with consistency.

THE LEAK TEST

THE LEAK TEST

THE LEAK TEST

THE LEAK TEST

THE LEAK TEST

The purpose of a leak test is to make sure the unit is air tight. You can tell if your unit has a leak if the pressure gauge

reading on your air checker starts to fall once the unit has been pressurized. Leaks will most likely occur at the main

seal or wherever o-rings or gaskets are located. The exact location of a leak can usually be detected by brushing

a soap and water solution around the main seal and where o-rings or gaskets meet the exterior of the unit then

checking for air bubbles. If a leak is detected in a seal, o-ring, or gasket, the part must be replaced.

TIGHTENING AND TORQUING BOLTS

TIGHTENING AND TORQUING BOLTS

TIGHTENING AND TORQUING BOLTS

TIGHTENING AND TORQUING BOLTS

TIGHTENING AND TORQUING BOLTS

If an air impact wrench is used to tighten bolts, extreme care should be taken to insure that the bolts are not tightened

beyond their indicated torque specification. Never use an impact wrench to tighten should bolts; all shoulder bolts

should be tightened by hand.

The following steps describe the proper procedure for tightening and torquing bolts or socket head cap screws in a

bolt circle.

1. Tighten (but do not torque) bolt “A” until snug.

2. Go to the opposite side of the bolt circle and tighten bolt “B” until equally snug.

3. Continue around the bolt circle and tighten the remaining bolts.

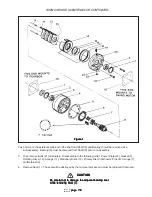

SWING MOTOR GEARBOX MAINTENANCE (S10A)

SWING MOTOR GEARBOX MAINTENANCE (S10A)

SWING MOTOR GEARBOX MAINTENANCE (S10A)

SWING MOTOR GEARBOX MAINTENANCE (S10A)

SWING MOTOR GEARBOX MAINTENANCE (S10A)