page 80

page 80

page 80

page 80

page 80

475 A CRL

800-00167

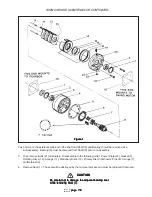

5. Remove Retaining Ring (2) and Bearing (3) from Housing (4).

6. Oil Relief Plug (23) should not be removed from Power Plate (20) unless the hole is contaminated. The plug

should then be removed to allow the hole in the power plate to be cleaned.

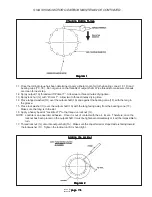

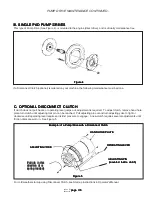

Figure 1

Figure 1

Figure 1

Figure 1

Figure 1

BRAKE RE-ASSEMBLY PROCEDURE

BRAKE RE-ASSEMBLY PROCEDURE

BRAKE RE-ASSEMBLY PROCEDURE

BRAKE RE-ASSEMBLY PROCEDURE

BRAKE RE-ASSEMBLY PROCEDURE

1. All parts must be thoroughly clean prior to re-assembly.

2. IMPORTANT:

IMPORTANT:

IMPORTANT:

IMPORTANT:

IMPORTANT: There may be more parts in a service kit than your brake requires. Check parts list care-

fully for the exact quantity. In the case of springs, space the required quantity equally.

3. Generally use the reverse of the disassembly procedure to re-assemble the brake.

4. Cylinder of the power plate, piston, and o-rings must be clean prior to assembly, and pre-lubed with

system hydraulic fluid.

5. Assemble Piston (14) into Power Plate (20) using a shop press, being careful not to damage the O-rings

or the Teflon back-up rings.

SWING BRAKE MAINTENANCE CONTINUED...