10-10

®

SAFETY SUMMARY

(continued...)

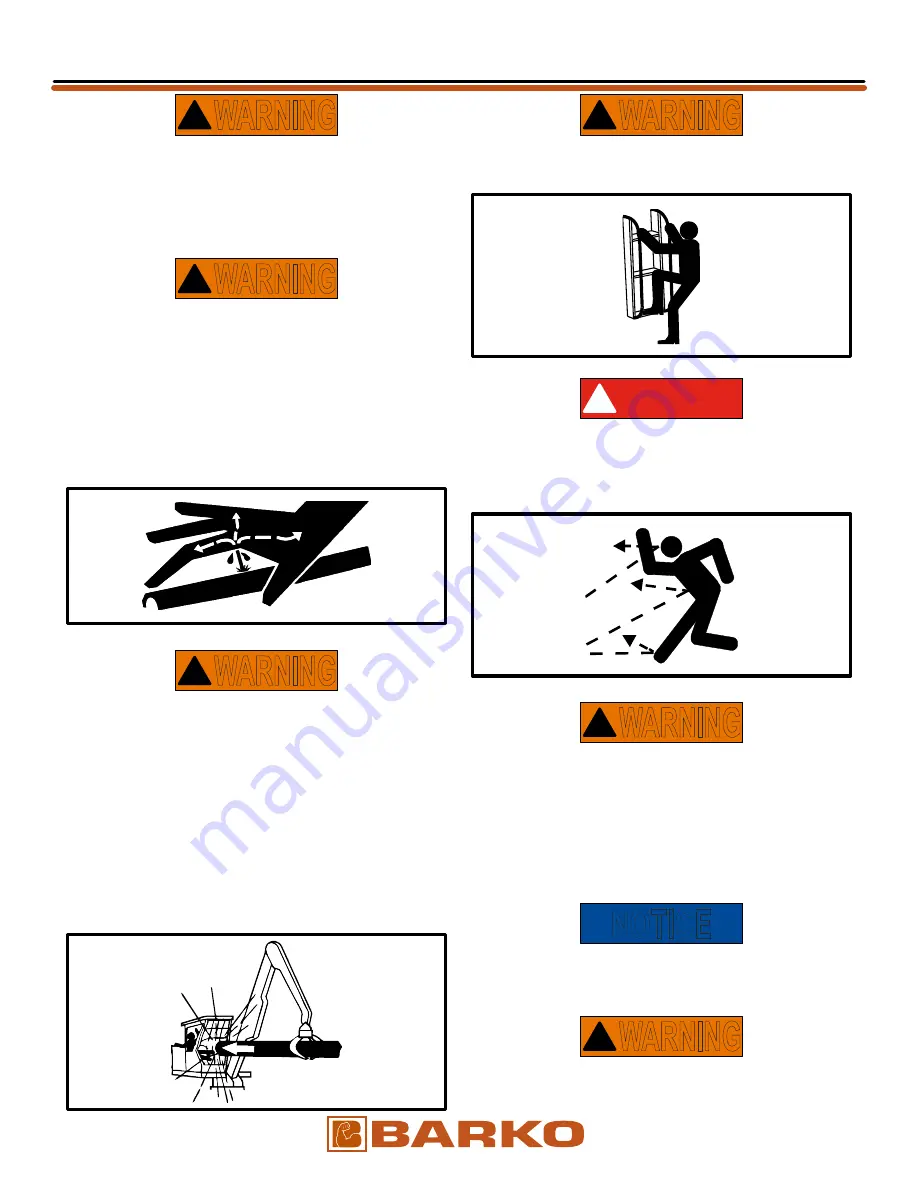

If machine malfunctions during operation, stop

machine motion as quickly as possible, lower boom

to the ground and shut down the machine.

Service or

repair the machine as needed before running or operating

again.

Always maintain 3-point contact with handles and

steps when mounting or dismounting.

Never jump on

or off machine. Do not rush. Walk, do not run.

High pressure hydraulic fluid can penetrate skin

causing death, gangrene or other severe injury.

Seek

immediate medical help to remove fluid.

Ÿ

Keep hands and body away from areas ejecting fluid.

Use piece of cardboard to check for leaks. Wear

proper hand and eye protection.

Ÿ

Relieve hydraulic pressure before loosening any

hydraulic connections.

Ÿ

Tighten all hydraulic connections before applying

hydraulic pressure.

FLYING DEBRIS will cause death or severe injury.

Do

not start up attachment until all personnel are 500 feet

from attachment and on opposite side of machine from

where debris and cutting chips will be thrown from

attachment. Shut down attachment when not in use.

Grease all boom, cylinder, and turntable bearing and

pinion points daily.

Loose or over-torqued bolts can cause death, severe

injury, or property damage.

Maintain proper bolt torque.

Visually check bolts daily. Check torque every 50 hours.

Mechanically connected controls will cause

movement of components at all times - EVEN IF

PUMP OR ENGINE IS NOT OPERATING.

Always be

certain that boom and attachment are properly supported

or resting on firm ground before stopping engine to

minimize chance of accidental movements of components

causing death, severe injury or property damage

Improper load handling and/or hydraulic pressure

loss can cause load to impact cab guard, resulting in

death or severe injury.

Ÿ

Do not rely on guard alone for personal protection. Use

safe and proper load handling techniques.

Ÿ

Do not operate machine with damaged or unsecured

guard or cab.

Ÿ

Do not repair damaged guard. Replace with factory-

authorized guard.

Ÿ

Do not modify guard without factory authorization.

Ÿ

Do not operate before conducting Pre-Start

Maintenance Inspection. Check hydraulic components

for leaks, loose fittings or damage.

WARNING

!

WARNING

!

WARNING

!

WARNING

!

DANGER

!

WARNING

!

WARNING

!

NOTICE

07/12/2018

Updated

OPERATOR’S

Summary of Contents for 295B

Page 4: ...THIS PAGE INTENTIONALLY BLANK SUPERIOR WI USA www barko com...

Page 6: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Page 27: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Page 60: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Page 64: ...THIS PAGE LEFT INTENTIONALLY BLANK...