43-4

®

TURNTABLE BEARING- ML

(continued...)

WARNING

!

WARNING

!

Fig-1

INSPECTION

(continued...)

Ÿ

Re-check mounting bolt torque every

100 hours of operation

.

Ÿ

Should any loss of pretension be detected, the source must be determined and eliminated.

The bolts should be checked again

after each additional 50 hours of operation

until loss is

no longer detected.

MOUNTING BOLTS

Ÿ

Mounting bolts should be checked by the end user

after the first 50 operating hours

.

Ÿ

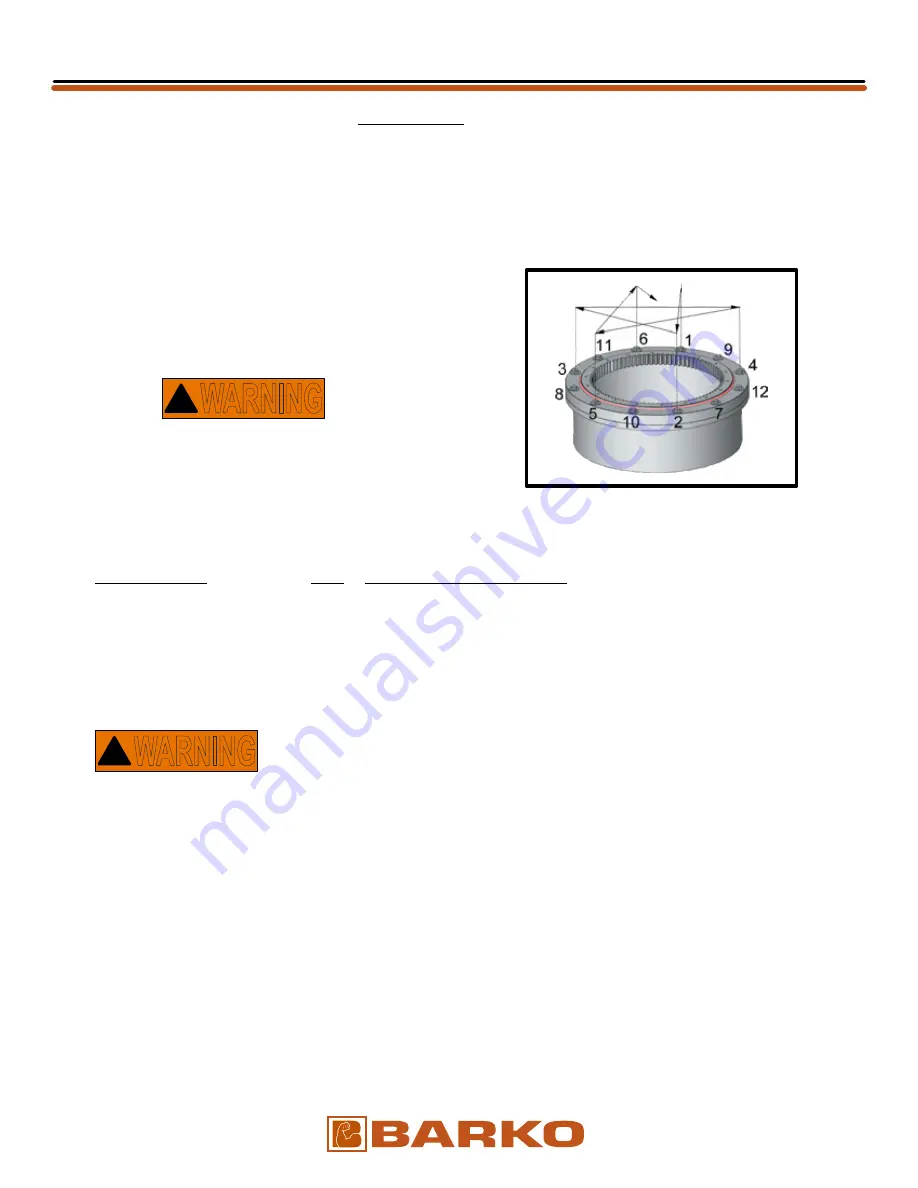

A common fastener torque sequence is the star

pattern tightening following the steps below. This

is usually done in 3 steps at approximately 30%,

80%, and 100% of the final torque or tension level

prescribed the machine specifications.

See Fig-1

for the torque sequence.

Maintain proper bolt torque.

Visually

check bolts daily. Check torque every 100

hours.

Loose or over-torqued bolts can cause

death, severe injury or property damage.

ML TURNTABLE BEARING, MOUNTING, & SPECIFICATIONS

DESCRIPTION

QTY BARKO SPECIFICATIONS

Turntable Bearing

1

3/4” Mounting Bolts

36

torque to 331 ft-lbs, use anti-seize

Ÿ

bearing to platform

Ÿ

lower frame to bearing

*DO NOT RE-USE TURNTABLE MOUNTING BOLTS OR WASHERS!

However mounting bolts may be re-torqued and torque should be checked

regularly, if any mounting bolts break or if the swing bearing is being removed

and replaced,

ALL NEW MOUNTING BOLTS AND WASHERS MUST BE

USED.

Failure to do so could result in catastrophic failure to machine

mounting.

08/20/2018

Updated

OPERATOR’S

Summary of Contents for 295B

Page 4: ...THIS PAGE INTENTIONALLY BLANK SUPERIOR WI USA www barko com...

Page 6: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Page 27: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Page 60: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Page 64: ...THIS PAGE LEFT INTENTIONALLY BLANK...