Service Manual

495B SE (S)

45

Last Updated - 9/28/2016

A heavy wall tubing and multi-wire hose network carries the hydraulic oil from the reservoir to the pumps and valves

and then to cylinders and motors and finally back to the reservoir.

Operating pressure of the hydraulic system varies from model to model. For your loader, consult the Hydraulic

Pressure Warning Sheet in this manual.

Replace any tubelines which are bent or have become flat. There will be a restriction of fluid flow which will make

hydraulic action slow and cause heat. Replace hoses which show signs of wear, damage, or weather-cracked rubber.

When making repairs on hydraulic system keep all parts clean and remove all dirt from the area

before you disassembly Use caps and plugs to keep dirt out of tubelines and openings.

PIPE THREAD SEALER

The main causes of air being introduced into a hydraulic system are loose connections and fittings. This not only

creates aeration in the fluid but also provides the risk of contamination entering the fluid and components with the air.

The easiest way to effectively reduce and possibly eliminate this problem is to use an adequate pipe thread sealer at

all connections and fittings.

While other pipe thread sealers may meet specifications, the methods which Barko uses are Teflon tape, and Locktite

Teflon Thread Sealer.

The sealer will form a flexible, non-hardening seal that can be easily broken at any time without stripping the threads

or damaging the pipes or fittings. It will also provide a non-shrinking bond that will inhibit rust or corrosion in the

threads and will not gall, seize, or block the threads.

APPLICATION

The pipe thread sealer is intended for use on threaded steel pipe in fixed installations. It can be easily applied by the

tube it comes in. This sealer is intended for use with petroleum fluids only. Apply sealer sparingly and leave the first

two threads near the end of the pipe or fitting bare.

Barko recommends the use of pipe thread sealer on all exterior pipe plug threads and pipe fittings.

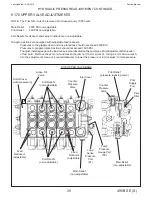

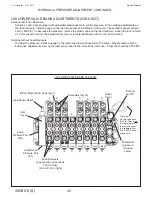

HYDRAULIC FITTINGS, HOSES & TUBING

Summary of Contents for 495B - SE

Page 3: ...Introduction...

Page 15: ...Maintenance...

Page 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Page 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Page 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

Page 28: ...Hydraulic...

Page 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Page 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

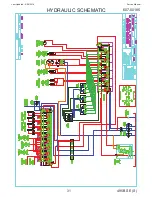

Page 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

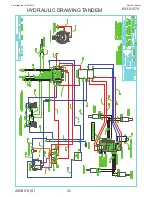

Page 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

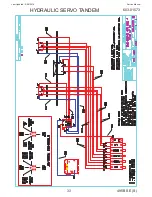

Page 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

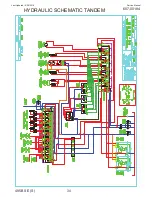

Page 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Page 56: ...Electrical...

Page 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

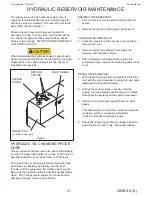

Page 78: ...Maintenance...

Page 88: ...Structural...

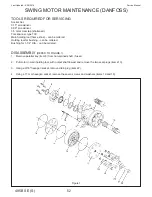

Page 93: ...Trouble Shooting...