Service Manual

Last Updated - 9/28/2016

495B SE (S)

50

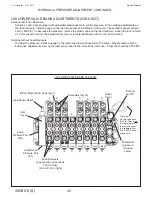

COLLECTOR TROUBLE SHOOTING CONTINUED...

5. Walk the clean or new thrust washer down the spool from seal groove to flow groove. Install the lower dust

shield o-ring onto the spool.

6. Using new clean oil, lightly oil the back-up o-rings, seals, and the stretching mandrel.

7. Install only the first back-up o-ring onto the spool (DO NOT install all of the back-up o-rings at once!).

8. Using your finger tips, (not fingernails) gently work the first seal down onto the stretching mandrel and allow at

least 5 minutes before removing.

9. After five minutes on the stretching mandrel, remove the stretched seal. Gently insert the I.D. of the seal into the

1st seal groove and gently walk it into the next seal groove. Then gently work the seal into the 1st flow groove

and repeat from flow groove to seal groove and so on until you get it in place over the first back-up o-ring that

you installed. Do not stop during this process because the stretched seal will want to go back to its original

shape making it more difficult to install without damage.

NOTE: If any seal appears to be damaged during installation, cut it off and start with a new one.

10. Once the seal is positioned over the back-up o-ring, gently place the loosened resizing clamp assembly over the

seal and SLOWLY tighten the clamp as you continually check that the seal is lined up with the groove. Tighten

until the clamp is firmly in place. The clamp can be removed by the time you get the next back-up o-ring and

seal in place.

This seal assembly process is to be repeated until all of the back-up o-rings and seals are installed and resized.

DO NOT use hooks, picks, screwdrivers, etc. to stretch or locate the seals.

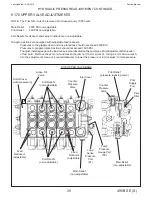

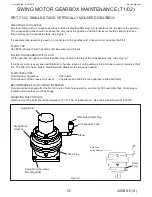

Figure 3

Housing

Cap Screws and

Lock Washers

Seals over Back-up

O-rings

Dust Shield O-ring

Spool

Retaining

Plate

Nylon Thrust Washer

PORT 1

PORT 2

(on left)

PORT 3

(on right)

PORT 4

1

2

3

4

1

2

3

4

3

4

1

Wear

Ring

Wear

Ring

Lower Nylon Thrust

Washer

Lower Dust Shield O-ring

Summary of Contents for 495B - SE

Page 3: ...Introduction...

Page 15: ...Maintenance...

Page 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Page 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Page 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

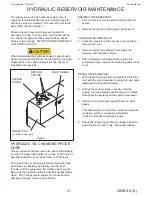

Page 28: ...Hydraulic...

Page 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Page 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

Page 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

Page 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

Page 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

Page 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Page 56: ...Electrical...

Page 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 78: ...Maintenance...

Page 88: ...Structural...

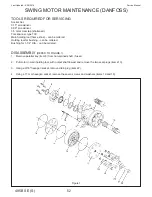

Page 93: ...Trouble Shooting...