Service Manual

495B SE (S)

55

Last Updated - 9/28/2016

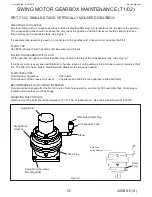

SWING MOTOR GEARBOX MAINTENANCE (T1/02)

RRT-T1/02 SINGLE-STAGE, VERTICALLY MOUNTED GEARBOX:

CHECKING FLUID LEVELS

An elbow fitting (with an oil expansion tank and an oil breather/filler plug in it) is located in the top side of the gearbox.

The oil expansion tank should rise above the very top of the gearbox, and the fluid level should be kept at just less

than half way up the expansion tank. See Figure 1.

If a separate lube reservoir is used (it is connected to the gearbox with a hose),it must be kept at half full.

FLUID TYPE

Use EP80-90 Gear Fluid in gearbox and lube reservoir (if used).

FILLING THE GEARBOX WITH FLUID

Fill the gearbox through the oil breather/filler plug located in the top of the oil expansion tank. See Figure 1.

If a lube reservoir is used, keep adding fluid to the lube reservoir until gearbox is full and lube reservoir remains at half

full. The filler cap has a built-in breather which allows air to escape as needed.

FLUID CAPACITIES

Fluid capacity of gearbox ............................ 9.09 quarts.

Fluid capacity of lube reservoir (if used) ......

2 quarts (keep at half full once gearbox is filled with fluid).

RECOMMENDED FLUID CHANGE INTERVALS

Fluid should be changed after the first 50 hours of machine operation, and every 400 hours after that. Drain plug is

located under gearbox mounting flange.

MOUNTING BOLT TORQUE

Gearbox mounting bolts should be torqued to 127 Ft. Lbs. of lubed torque. Use anti-seize lubricant 514-00700.

Figure 1

Swing Motor

Drain Plug

Swing Motor

Gearbox

Fluid Level

inside Gearbox

Swing Motor Gearbox

Mounting Bolts

Drain

Plug

Oil Expansion Tank

Oil Breather/Filler Plug

Elbow

Summary of Contents for 495B - SE

Page 3: ...Introduction...

Page 15: ...Maintenance...

Page 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Page 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Page 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

Page 28: ...Hydraulic...

Page 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Page 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

Page 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

Page 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

Page 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

Page 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Page 56: ...Electrical...

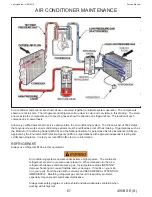

Page 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 78: ...Maintenance...

Page 88: ...Structural...

Page 93: ...Trouble Shooting...