Service Manual

Last Updated - 9/28/2016

495B SE (S)

60

ELECTRICAL SYSTEM DESCRIPTION

This machine has 12 Volt electrical system with alternator, negative ground, and 12 Volt battery.

There are two basic circuits in the electrical system:

1. Charging circuit (alternator and battery).

2. Starting circuit (switch, solenoid, battery, and starter).

NOTE: Disconnect battery ground cable before making any repairs to electrical circuits.

In addition to the two basic circuits, there is an accessories circuit and operating light circuit(s).

ELECTRICAL SYSTEM INSPECTION

Check for:

- Clean and tight battery cables. Be sure all cables are clean and tight. Remove any acid or corrosion from

battery cables with baking soda and water solution. Cover terminals with grease to prevent corrosion.

- Proper tension on drive belt for alternator. For drive belt adjustment, see ALTERNATOR DRIVE BELT

ADJUSTMENT information.

- Loose wire connections. Be sure all wires are tightly connected.

- Broken or open wires. Replace any wires that are damaged or worn.

- Proper electrolyte level in battery. Add distilled water if necessary.

- Proper voltage of battery. Charge if necessary.

NOTE: See ELECTRICAL Section in Parts Manual for parts information, layouts and hookups.

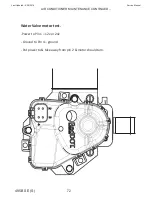

BATTERY DISCONNECT SWITCH

Located on side of shrouding behind cab door.

Breaks positive circuit between battery and all points

on machine.

This switch should be used to disconnect battery

circuit when transporting machine and whenever

false starts or electrical damage need be prevented.

Turn switch to OFF to disconnect battery circuit.

Turn switch to ON to connect battery circuit.

If welding is to be done on machine:

1) Get factory authorization.

2)

Disconnect

battery.

3) Disconnect electronic throttle.

4)

Disconncet

radio.

Damage to components will occur if the

above procedures are not followed.

ELECTRICAL SYSTEM MAINTENANCE

OFF

ON

CAB

SHROUDING

Summary of Contents for 495B - SE

Page 3: ...Introduction...

Page 15: ...Maintenance...

Page 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Page 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Page 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Page 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

Page 28: ...Hydraulic...

Page 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Page 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

Page 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

Page 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

Page 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

Page 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Page 56: ...Electrical...

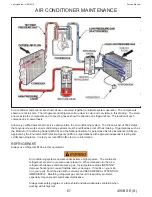

Page 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

Page 78: ...Maintenance...

Page 88: ...Structural...

Page 93: ...Trouble Shooting...