7

GB

must be properly installed and grounded.

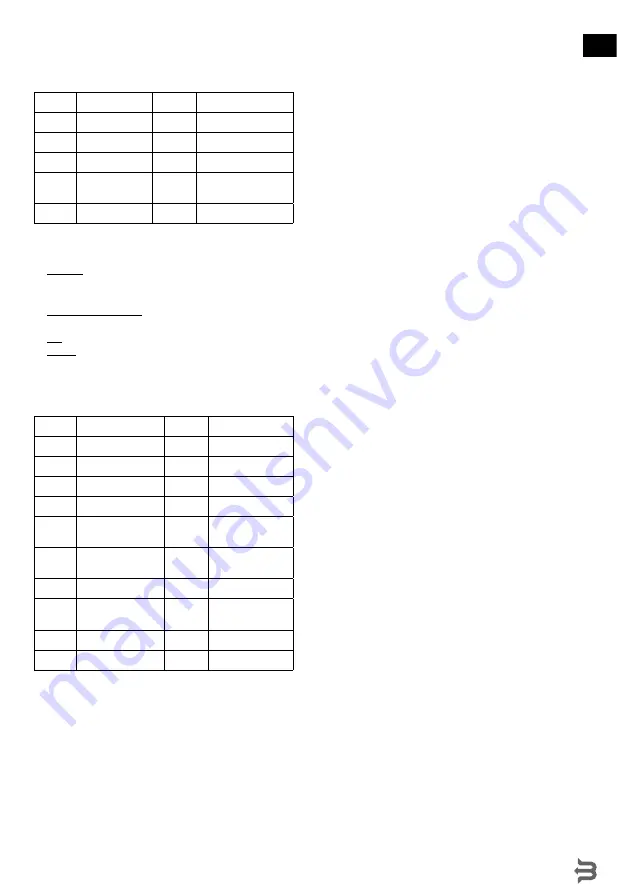

Operating principle

(Fig.1 on page 3)

Symbol

Description

Symbol

Description

C

Compressor

SC

Cycle probe

V

Fan

SA

Ambient probe

B

Pump

P

High pressure switch

EA

Water inlet

valve

T

Bin thermostat probe

GC

Hot gas valve

Control panel

(Fig.2 on page 3)

1. ON/OFF: Power on: lights up the screen and starts at point

0. Powe off: It turns off the appliance at any time. It turns off

the display light and leaves the time showing. All relays off.

2. UP / DOWN ARROWS: Moving between menu options. In-

creasing or decreasing values.

3. OK: Confirmation the menu options or set values.

4. MENU: Entering to the main menu or back from one setting

level when navigating the menus.

Electric circuit diagram

(Fig.3 on page 3)

Symbol

Description

Symbol

Description

#1

blue

#2

red

#3

brown

#4

back

#5

orange

#6

violet

#7

white

#8

grey

H

High pressure

switch

L

Low pressure

switch

SA

Air temperature

probe

SC

Cycle temperature

probe

T1

Bin thermostat

P

Water electrovalve

Q

Hot gas electro-

valve

S

Compressor

B

Pump

R

Fun

F

Fan control

Preparation before use

• Remove all protective packaging and wrapping.

• Check that the device is in good condition and with all ac-

cessories. In case of incomplete or damaged delivery, please

contact the supplier immediately. In this case, do not use the

device.

• Clean the accessories and the appliance before use (See ==>

Cleaning & Maintenance).

• Make sure the appliance is completely dry.

• Place the appliance on a horizontal, stable and heat resistant

surface that is safe against water splashes.

• Keep the packaging if you intend to store your appliance in

the future.

• Keep the user manual for future reference.

NOTE!

Due to manufacturing residues, the appliance may emit

a light odor during the first few uses. This is normal and does

not indicate any defect or hazard. Make sure the appliance is

well ventilated.

Operating instructions

Installation

• Use the flexible connection (length 1.3 m.) with the two filter

joints supplied with the appliance. We do not advise the use

of double water outlet with two stopcocks as they may close

the rear one by mistake, leaving the appliance without water.

Water pressure must be between 1 Bar and 6 Bar. If the pres-

sure exceeds these values, install the necessary corrective

components.

• It is important that the water line does not pass close to

sources of heat, and that the flexible hose or the filter does

not receive hot air from the appliance. It could cause de-

creasing of production.

• The drain must be below the appliance, by at least 150 mm.

• In order to prevent bad smells, install a siphon. The drainage

pipe should have an internal diameter of 60 mm and a mini-

mum slope of 3 cm per metre.

• The electronic board has a button battery for timer. During

installation, please remove the protection (board in the upper

side, behind the display - remove two screws under the upper

air grille, to access the electric box).

Start up

After installation (checking ventilation, conditions of the prem-

ises, temperature, water quality, etc.), proceed as follows:

• Open the water inlet. Check that there are no leaks.

• Connect the appliance to the mains.

• Push the button on the display.

• Check that there is no part which is rubbing or vibrating.

• Check that the curtain can move freely.

• Check that the injectors send the water to the evaporator in

the correct direction.

• Check that the collectors turn freely on their axles.

• Once 10 minutes have passed, check that the water container

has no leaks through the maximum level overflow channel.

Control panel

• The time is shown on the display when the appliance is off

(no backlight). When the appliance is disconnected from the

power supply the time is lost. When reconnected time 00:00

will flashing to indicate that the time is not set.

• During the start up, on display will appear “Starting”.

• During the detachment time, on display will appear “Har-

vest”. At the bottom of the screen it will show the tempera-

ture indicated by the cycle probe (SC).

• When the detachment has finished the screen will show a

progress bar with the time remaining until the end of the cy-

cle. It will also show the following text at the bottom of the

screen: “Fabr.: -12ºC”, with the temperature indicated by the

SC cycle probe.

• As the production time is “tf=tfv+tff” and at the start it is not

known how long the “tfv” will last, since it depends on the

“Tfc”, take as a reference: cooling time “tfv” of the last cycle

+ set production time “tff”.

Summary of Contents for ICE400

Page 3: ...3 1 2 3...

Page 51: ...51 GR Barmatic 20 cm R452A...

Page 55: ...55 GR 2 t 60 t Freez t Freez t t 20 2 t OK OK 50 35o 40oC 3 10 10...

Page 56: ...56 GR 7oC...

Page 76: ...76 UA 20 R290 I...

Page 80: ...80 UA 50 35o 40oC 3 10 10...

Page 81: ...81 UA 7 oC 710 6 2 _____ 30 2 ON 60 2...

Page 148: ...148 BG 20 R452A I 1 3 C SC V SA B P EA T GC 2 3 1 0 Powe 2 3...

Page 152: ...152 BG 3 10 10 7 C...

Page 153: ...153 BG 710 6 2 _____ 30 bar 2 60 2 harv time long freez time short freez time...

Page 154: ...154 RU Barmatic 20 R452A...

Page 158: ...158 RU 10 10 7oC...