23

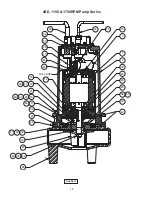

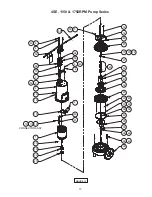

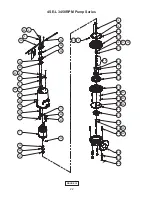

PARTS KITS

Seal Repair Kits

Double Seal........P/N - 130178

(†) 32, 42, 46, 57

Service Kits

Double Seal........P/N - 130174

(♦) 11, 12, 29, 30, 32, 33, 34, 35, 42, 46, 47, 54, 57

Seal Tool Kit ............................ P/N-085736

Pressure Gauge Kit ................ P/N-085343

PARTS LIST

ITEM

QTY

PART NO.

DESCRIPTION

NOTES

1

1

088754

Motor, 4SE5032L, 4SE5042L

230/460V, 3Phase, 3450RPM

088756

Motor, 4SE5052L

575V, 3Phase, 3450RPM

2

1

114492HA

Motor Housing, Double Cords

Power and Sensor Cord (STD)

1

114492

Motor Housing, Single Cord

Power Cord ONLY (Optional)

4

6

026322

5/16” Lock Washer

SS

5

2

014270

3/8” NPT Pipe Plug

ZP

6

6

1-156-1

HXHD Cap Screw

5/16-18 x 1” LG, SS

7

1

103503

Handle

SS

9

4

20-13-1

1/4” Lock Washer

SS

10

2

625-02117

Fiberglass Sleeve

230V, 3Phase

1

625-02117

Fiberglass Sleeve

460V, 3Phase, 575V, 3Phase

11

4

105150

Wire Crimp Connector

230V, 3Phase

3

105150

♦

Wire Crimp Connector

460/575V, 3Phase

12

3

105149A

♦

Jumper Wire

230V, 3 Phase

13

150 oz.

029034

Oil- Motor Housing

40 oz.

029034

Oil - Seal Cavity

14

2

038156

Machine Screw

#6-32 x 3/8” LG, ZP

16

1

133403B

Moisture Sensor Wire

Red

1

133403A

Moisture Sensor Wire

Orange

18

2

066843

Moisture Electrode

19

4

20-14-1

3/8” Lock Washer

SS

20

4

15-23-1

3/8-16 Hex Nut

SS

21

1

065892

Bearing Bracket

CI

24

4

066103

Stud

3/8-16 x 3-7/8” LG, SS

25

1

065893

Seal Plate

CI

26

1

066744

Volute

CI

27

2

039934

Moisture Electrode Cap Plug

28

1

Impeller, Cast Iron

088545

5.00” Dia. (STD)

088545TA

4.88” Dia.

088545TB

4.75” Dia.

088545TC

4.63” Dia.

088545TD

4.50” Dia.

088545TE

4.38” Dia.

088545TF

4.25” Dia.

088545TG

4.13” Dia.

088545TH

4.00” Dia.

088545TJ

3.88” Dia.

088545TK

3.75” Dia.

088545TL

3.63” Dia.

088545TM

3.50” Dia.

29

1

066130

♦ Retaining Ring

30

1

057882

♦ Retaining Ring

31

2

003217

1/4” NPT Sq. Pipe Plug

ZP (When Item 18 Not Used)

32

1

022873

†♦ Diaphragm

Buna-N

33

1

057554

♦ Shaft Key

3/16 Sq x .585” LG, SS

34

1

038132

♦ 5/8-18Hex Nut

SS

35

1

070320

♦ 5/8” Flat Washer

SS

4SE-L 3450RPM Pump Series

(*) Included with item number 10.

Summary of Contents for 4SE-L series

Page 14: ...14 FIGURE 11...