Hydraulic Oil Supply

Important

Do not mix different types of oil.

Important

Use Shell Tellus S2M46 (or equivalent) as

hydraulic oil.

In case of an equivalent, consult

Characteristics of Hydraulic Oil and use

hydraulic oil whose characteristics are

superior to those of the specific hydraulic oil.

Especially regarding kinematic viscosity and

viscosity index, use of hydraulic oil whose

figures are less than those of the specified

hydraulic oil will cause a malfunction in the

hydraulic circuit.

Note:

Characteristics of Hydraulic Oil

Specified Hydraulic Oil

Shell Tellus S2M46

ISO Viscosity Grade

ISO VG46

Density

15 °C (59 °F)

0.873 g/cm

3

(0.0315 lb/in

3

)

API Gravity

30.6

Flash Point (Open Cup)

230 °C (446 °F)

Pour Point

-30 °C (-22 °F)

Kinematic

Viscosity

40 °C (104 °F)

46 mm

2

/s (46 cSt)

100 °C (212 °F)

7 mm

2

/s (7 cSt)

Viscosity Index

109

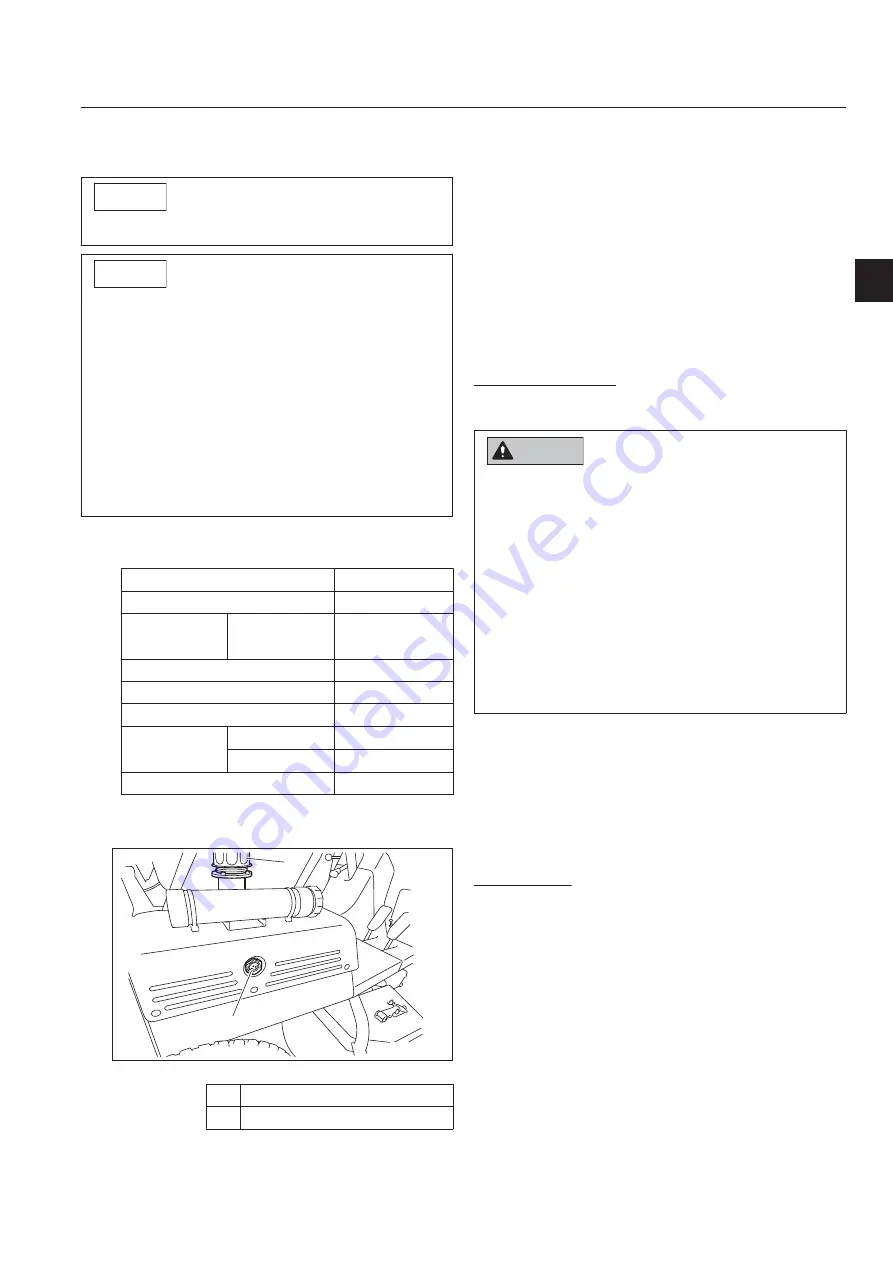

If the oil level is low, open the tank cap and

supply oil.

1

2

dmhzyz-011

Hydraulic Oil Supply_001

1

Tank cap

2

Oil gauge

Securely close the tank cap.

1.

2.

Start the engine, raise and lower the mower

decks, and turn the steering wheel left and

right.

Move forward and reverse repeatedly

several times.

Raise the mower decks and maintain that

position on a level surface, and then check

to see if the oil level is at the middle of the

oil gauge. If necessary, supply oil.

Check underneath the machine for oil

leakage.

Hydraulic Hoses

Inspection of Hydraulic Hoses

Warning

When checking the hydraulic circuit for

pinhole leaks or oil leakage from nozzles, do

not use your hands. Use items such as paper

or corrugated cardboard to find leakage

points.

Be extremely careful with high-pressure oil as

it may pierce your skin, resulting in personal

accidents.

If fluid is injected into the skin it must be

surgically removed within a few hours by a

doctor familiar with this form of injury or

gangrene may result.

Check the pipes and hoses to make sure that

there is no oil leakage, circuit damage,

looseness, wear, connector looseness,

weather deterioration and chemical

deterioration.

Make any necessary repairs before operating

the machine.

Air Cleaner

Inspection of Air Cleaner

The air cleaner is a component that removes

dirt from the intake air to prevent wear of the

cylinder liners and piston rings so that the

engine will always operate smoothly.

A contaminated air cleaner element may

cause malfunction of the engine.

Make sure that there is no damage to the

air cleaner.

3.

4.

5.

1.

Handling Instructions

GM1700

Handling Instructions

Page 4-5

Inspections

Summary of Contents for GM1700

Page 6: ...GM1700 Introduction...

Page 8: ...GM1700 Contents...

Page 14: ...GM1700 Safety Page 1 6 Safe Operating Practices...

Page 58: ...GM1700 Handling Instructions Page 4 30 Storage...

Page 82: ...GM1700 Maintenance Page 5 24 Maintenance Work...

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......