Rear Cover

Warning

Stop the engine when performing

recommended maintenance operations that

do not require the engine to start when the

rear cover is opened.

When performing maintenance with the

engine started, stay away from moving parts.

Caution

Do not open the cover in strong winds.

Caution

When closing the cover, be careful not to

pinch your hands.

The rear cover is under the seat and is opened

in order to perform maintenance.

Release the cover fastener.

2

1

uemj7o-001

Rear Cover_001

1

Cover fastener (released)

2

Rear cover

Open the rear cover, and then lift it until the

gas spring is fully extended.

1

2

uemj7o-002

Rear Cover_002

1.

2.

1

Rear cover

2

Gas spring

When closing the rear cover, slowly lower it

while firmly supporting it, and then engage

the cover fastener.

1

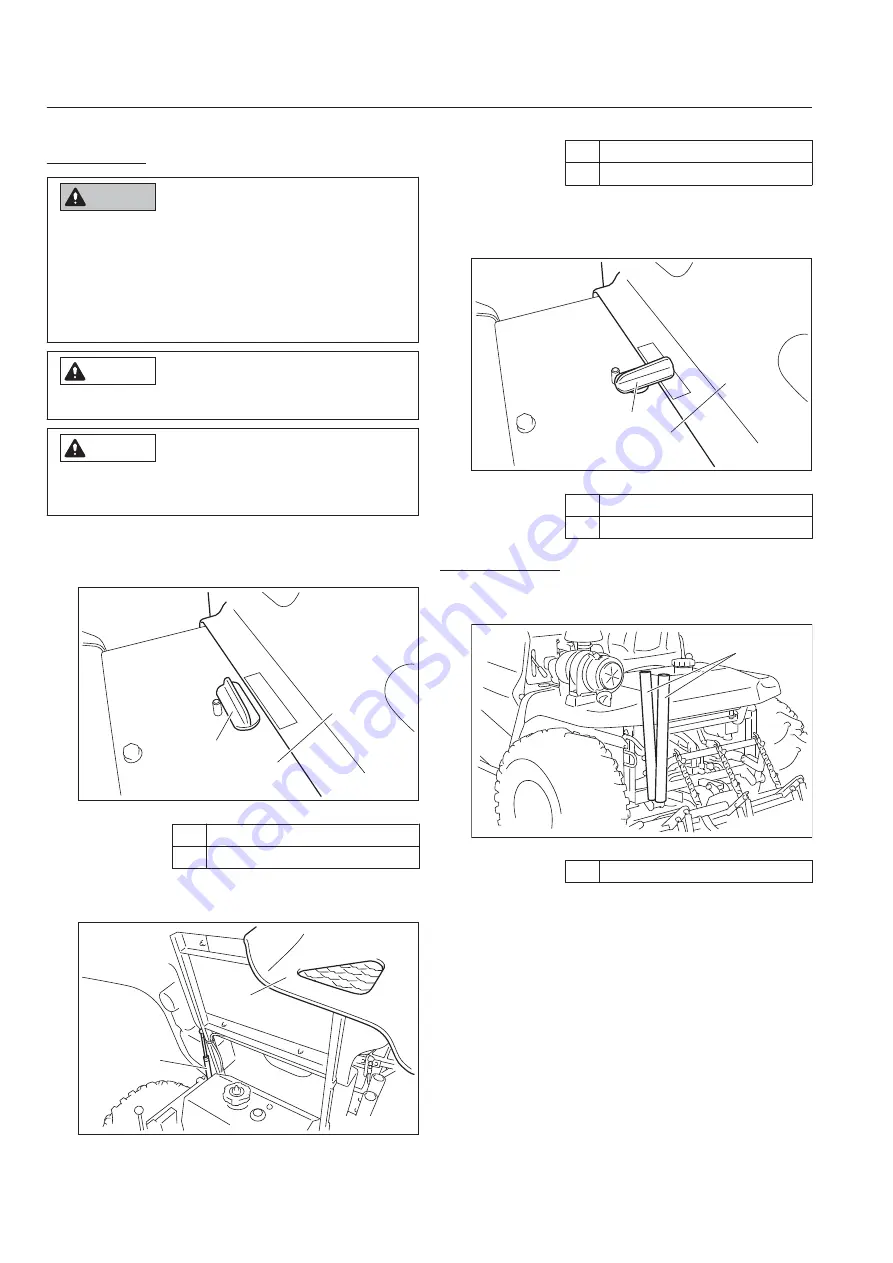

2

uemj7o-003

Rear Cover_003

1

Cover fastener (engaged)

2

Rear cover

Broom Holder

Broom and rake can be stored in these holders

for transport.

1

mdr5p1-003

Broom Holder_001

1

Broom Holder

3.

SP05A

Handling Instructions

Page 4-24

Operation Method

Summary of Contents for SP05A

Page 6: ...SP05A Contents...

Page 52: ...SP05A Handling Instructions Page 4 32 Storage...

Page 72: ...SP05A Maintenance Page 5 20 Maintenance Work...

Page 73: ......

Page 74: ......

Page 75: ......