#0-313A-SBA (6/01)

Page 13 of 14 pages

BARRETT CENTRIFUGALS INC.

1-800-228-6442

PLUMBING THE SPINDLE AND MOTOR BALANCING SPRING ADJUSTMENT

The balancing spring system is properly set up and plumbed at the factory. If your machine

is installed level no adjustment should be necessary. After extended use the springs may

need adjustment.

Proper tension of the balancing springs is imperative to insure a smooth running and well-

balanced machine. Excessive spring tension will cause unnecessary wearing of the pivot

assembly by excessive restriction of the oscillation. This will cause pounding and vibration,

which will transmit undue stress and strain to the spindle bearings, thereby shortening the

bearing life.

NEVER ATTEMPT TO ADJUST THE BALANCING SPRINGS WHILE THE MACHINE IS

RUNNING!!

To plumb the spindle, remove tension from the four balancing springs by backing off the jam

nuts. Plumb the rotating element using a level on top of the flat machined surface of the

carrier or pan support. Screw the bottom four nuts down until they bear lightly and evenly on

all four springs and the carrier registers plumb. (Tension at this point should be such that the

springs can be turned by hand.) Then tighten each nut two full turns and set the jam nuts

securely.

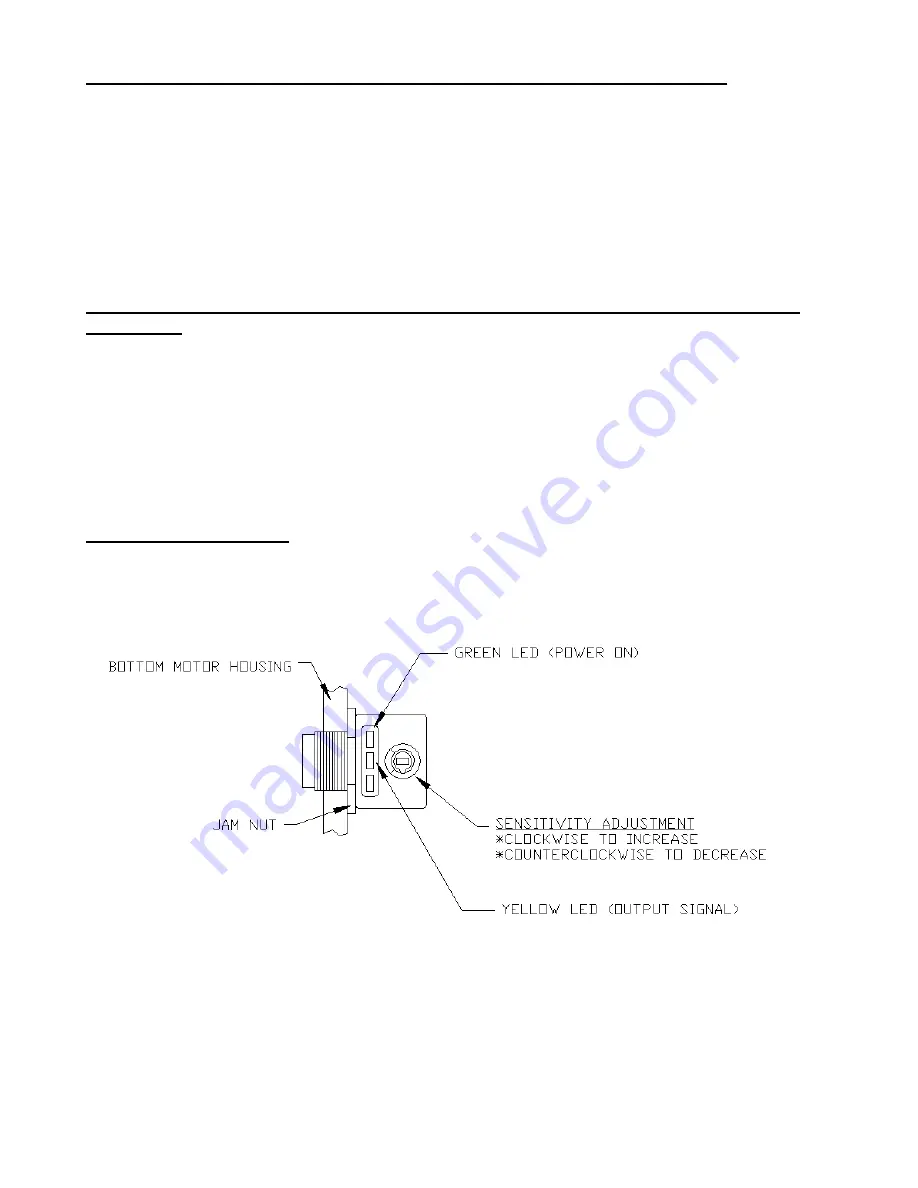

ROTATION DETECTOR

(Refer to Fig. 3)

The rotation detector is a PNP diffused mode photoelectric sensor mounted in the bottom

motor housing of the machine. It senses rotation by emitting light toward a

Fig. 3.

Rotation detector

notched cylinder attached to the bottom of the rotor and sensing the amount of light reflected

back. The sensor’s sensitivity is set at an optimum level at the Barrett factory. It should not

require adjustment. However, if it seems to be malfunctioning, check the following: