WAM™ Wrist – Cable Maintenance Guide support@barrett.com

www.barrett.com

© 2008 Barrett Technology®, Inc.

Document: D1004, Version: AG.00

Page 3 of 13

1 General Wrist Cable Circuit Descriptions

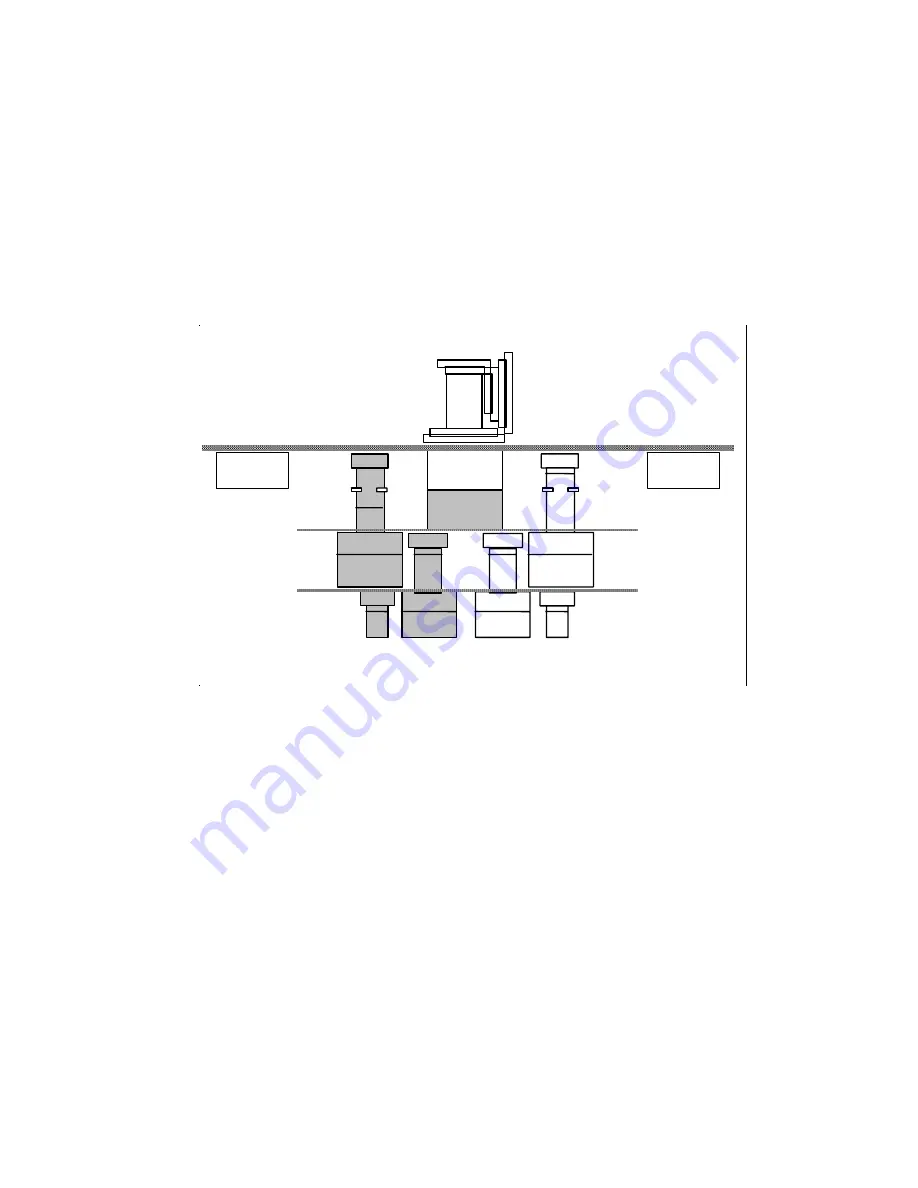

The Wrist has three distinct cabling regions: (1) the motor 5 (M5) transmission, (2) the motor 6 (M6) transmission, and (3) the

differential. Stages 1 through 3 of the motor transmission circuits are stages of reduction for the main motors in the base of the

Wrist. The differential circuit translates the rotations of the motor circuits (M5 and M6) into the main pitch and roll motion of the

Wrist. An exploded schematic of the entire Wrist, shown in Figure 1, outlines the three distinct cabling circuits.

Each stage of the cabling circuits, except the differential, is made up of one pulley and one pinion; the pinion having the smaller

diameter. In the M5 and M6 input circuits, the pinion

is

the motor shaft in stage 1. In stages 2 and 3, the reductions are

implemented with the pinion of each stage attached to the pulley on the stage beneath it. In the differential, all mating pairs of

pulleys are of identical size resulting in a 1:1 ratio. In the worm gear tensioning system, the worm gear on the level with the

smaller diameter creates pretension for differential levels 1 and 2, while the worm gear on the level with the larger diameter

creates pretension for differential levels 3 and 4.

M6

Differential

M6 3rd Stage

M6 2nd Stage

M6 1st Stage

M5 3rd Stage

M5 2nd Stage

M5 1st Stage

M5

Figure 1 -- Schematic Diagram of Wrist Cable Circuits

2 Helpful Tools & Tips

2.1 For First Time Cablers

Re-cabling the Wrist is generally easier if the user is familiar with cabling other mechanisms such as the WAM Arm. If the user is

cabling the Wrist for the first time, she should read this entire section on wrist cabling (especially Section 6.5 on pre-tensioning

input circuits) and section 1 of the WAM Arm cabling manual before beginning to cable the Wrist. Make sure that proper tools

and cable parts have been gathered prior to any cabling activities. Figure 2 shows the tools provided with the Wrist. You will also

need the wider masking tape provided in the 4-DOF WAM Maintenance kit. The cabling instructions have numbered checkboxes

next to each step for tracking progress. These pages may be photocopied for use as a cabling checklist.

Allow roughly 4 hours to cable one of the circuits for the first time. Subsequent cabling of the wrist after the user is familiar with

the instructions can be completed in 1 hour.

One important point to keep in mind is that each cable of a given drive must be held in place at all times until the entire circuit is

pre-tensioned. The wrapped cables act like light torsion springs which, when released, even momentarily, may quickly unravel

your work back to your starting point. This is the most common error for the first-time cabler. Pre-tensioning, which prevents this

unraveling, cannot be done until all cables in that circuit have been installed. Masking tape is a tremendous aid in temporarily

preventing this unraveling. As cables are wrapped onto each pulley or pinion, hold each wrap with your fingers to keep it from

unwinding. At the end of each cabling step, one or two pieces of masking tape temporarily immobilize transmission elements and

keep cables in place.