32

R

eliant

1500 M

anual

6. Too much weight in hopper.

1. Exessive weight in hopper.

2. Excessive down pressure on gate

assembly.

3. Off-centered product from center point of

machine.

4. Stack is bearing down on edge of belt.

5. Belt wear.

6. Rollers out of adjustment.

1. Improper adjustment in any of the

following areas:

•

Gate assembly

• Back wedge

• Hold-down assembly

1. Photo sensor "staging" leading edge of

material too short of hopper plate.

2. Gripper jaw adjusted too far from edge of

hopper plate.

1. Photo sensor "staging" leading edge of

material too far past hopper plate.

2. Gripper jaw adjusted too close to edge of

hopper plate.

1. Back wedge not adjusted properly.

2. Hold down spring too tight or too loose.

1. Sensor not seeing space between feeds.

Remove material from stack. Test again.

Reduce weight. Test again.

Rotate clockwise 1/8 turn to increase gap

and manually test. Review gate assembly

adjustment in Section 3 "Preparing for

Operation".

Review side guide setting in Section 3 "Pre-

paring for Operation".

Move stack away from belt, even if this

causes stack to be aligned off-center from

machine center line.

Review gate assembly adjustment in Sec-

tion 3 "Preparing for Operation". See also

Section 6 "Inspection and Care". If wear is

excessive, consult with a qualified techni

-

cian.

Consult with a qualified technician.

1. Turn the power switch to "Off".

2. Remove jammed material. Attempt to

determine the cause of the jam.

3. Verify each adjustment by reviewing Sec-

tion 3 "Preparing for Operation".

Review photo sensor adjustment in Section

3 "Preparing for Operation".

Adjust gripper jaw per inserter owner's

manual instructions.

Review photo sensor adjustment in Section

3 "Preparing for Operation".

Adjust gripper jaw per inserter owner's

manual instructions.

Review back wedge adjustment in Section 3

"

Preparing for Opertion".

Review hold-down spring installation in Sec-

tion 2 "Installing the Machine".

Reposition sensor. Review photo sensor

adjustment in Section 3: "Preparing for

Operation".

Table 2. Quick-Look Troubleshooting (continued)

Feed belts are operat

-

ing but material not

feeding (cont)

Feed belts not tracking

on rollers

Jamming occurs during

operation

Material too far from

gripper jaw

Material too deep in

gripper jaw

Material skewing

Motor not "staging"

new material

Problem

Cause

Solution

Summary of Contents for Thiele Technologies Streamfeeder Reliant 1500

Page 1: ...Manual Reliant 1500 ...

Page 12: ...6 Reliant 1500 Manual ...

Page 36: ...30 Reliant 1500 Manual ...

Page 46: ...40 Reliant 1500 Manual ...

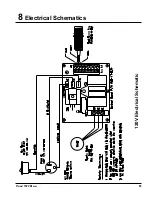

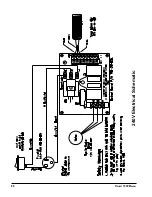

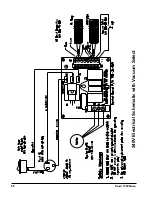

Page 49: ...43 Relaint 1500 Manual 8 Electrical Schematics 120V Electrical Schematic ...

Page 50: ...44 Reliant 1500 Manual 240V Electrical Schematic ...

Page 51: ...45 Relaint 1500 Manual 120V Electrical Schematic with Vacuum Select ...

Page 52: ...46 Reliant 1500 Manual 240V Electrical Schematic with Vacuum Select ...

Page 53: ...47 Relaint 1500 Manual 9 Mechanical Components ...

Page 57: ...51 Relaint 1500 Manual ...

Page 59: ...53 Relaint 1500 Manual ...

Page 61: ...55 Relaint 1500 Manual ...

Page 65: ...59 Relaint 1500 Manual ...

Page 67: ...61 Relaint 1500 Manual ...

Page 69: ...63 Relaint 1500 Manual ...

Page 70: ...64 Reliant 1500 Manual ...

Page 71: ......

Page 72: ... 2009 Thiele Technologies Inc Streamfeeder Printed in the USA ...