INSTALLATION GUIDELINES

34

the PTB mark of conformity (Lab. 3.43) completes the protective system for the maintenance of the

temperature class.

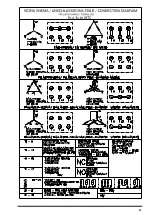

Electric motors with two velocities (two separate windings or one winding in Dahlander coupling)

must have a separate protection for each speed.

The housing of the electric motor must be connected to the protective conductor, and earthed. The

terminal box contains the screw for the connection of the conductor, the earthing screw sits on the

stator housing.

If the electric motor is supplied via the frequency converter, please make sure that the settings on

the converter correspond to the data indicated on the supplementary label. The electric motor must

be double-protected, i.e. with the motor circuit-breaker and the temperature protection. The

shutdown device connected to the temperature protection must be in the range of 2k

<Ro<4k

with Ro representing the shutdown resistance. The shutdown device must be certified.

7. MAINTENANCE

Electric motors have a robust structure and need no particular maintenance.

The motor must be cleaned in regular intervals (depending on the environment), especially the

entry openings on the fan as to guarantee a sufficient air flow for the cooling system.

Electric motors feature closed and prelubricated bearings. The life span of the bearings is 20000

service hours for 2 pol electric motors (ns=3000 min

-1

) under normal operating conditions or 40000

service hours for 4,6,8 and multiple-pol motors.

Regular inspections and control measurements carried out by qualified personel are preffered to

reduce possible damages and standstills.

Each deviation from the nominal values (such as higher load current, increased temperatures,

vibrations, unusual noise or smell, reactions of protective devices) is to be understood as signal of

possible damage! To prevent consequential damages on machines or people, please inform the

person responsible immediately on the appearance of such deviations.

8. REPAIRS

ELECTRIC MOTORS FOR EXPLOSIVE AREAS MAY BE REPAIRED EXCLUSIVELY BY THE

MANUFACTURER OR OUR AUTHORIZED REPRESENTATIVE.

THOSE WHO DISASSEMBLE AND REPAIR THE EX MACHINES MUST BE HIGHLY QUALIFIED

AND DISPOSE OF ADDITIONAL KNOWLEDGE CONCERNING EXPLOSION PROTECTION.

IMPORTANT:

Repaire according of flameproof gaps and joints according to table 2 of EN 60079-1 is not

allowed! Please conntact producer!

Special attention should be paid that no damaged has occured during disassembly on flameproof

gaps and joints.

Before assembly of electromotor all flameproof gaps and joints needs to be cleaned and greased

with grease type FOR PD-2 (Sestral MI PD LL/2A) or Renolit RHF-1 Fuchs.

If it becomes clear during repairs that the »explosion-proof enclosure« no longer corresponds to

the requirements on the explosion protection and specified in the certification, all markings for

explosion protection must be removed from this motor.

Summary of Contents for BM 4KTC71

Page 3: ...3...

Page 4: ...4...

Page 5: ...5...

Page 6: ...6...

Page 43: ...43...

Page 44: ...44...

Page 45: ...45...

Page 46: ...46...

Page 47: ...47...

Page 48: ...48...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...

Page 52: ...52...

Page 53: ...53...

Page 54: ...54...

Page 55: ...55...

Page 56: ...56...

Page 57: ...57...

Page 58: ...58...

Page 59: ...59...

Page 66: ......

Page 67: ...67...